Aluminium Production Process : (PDF) The Aluminum Smelting Process

Di: Luke

ALUMINA PRODUCTION Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water.Aluminum production processes are highly energy dependent, from mining to the final product.La production d’aluminium primaire à partir de l’alumine par le procédé Hall-Héroult est un processus électrolytique qui nécessite une énorme quantité d’énergie.Abbildung 1 – Primary aluminum production scheme: from original bauxite to aluminium products [2] Alumina from bauxites.

The aluminium production process

This is, however, not desirable for smelting, because -alumina is slow to dissolve in the bath (refer to Section 24).Aluminium electrolysis is .Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery.How is aluminium produced? Which raw materials are used and what processes are required in order to change the raw materials into pure aluminium? Read all about the . Aluminum Materials.It’s all in its primary production, which brings aluminium to life.Direct aluminium production process inventory data at the global level is published by the International Aluminium Institute per unit process (see Appendix I, Electronic Supplementary Material) and demonstrates, in part, the global aluminium industry’s dedication to report openly its environmental impacts.

comHow Aluminum is Produced | Metallurgy for Dummiesmetallurgyfordummies.The Product The purity of the aluminium produced in a cell depends on many factors including the age of the cell. Two to three tonnes of bauxite are required to produce one tonne of alumina. The final steps in aluminum can manufacturing involve assembling the top and bottom with the can body and sealing them together using a double-seam process.The aluminium production process can be broken down into three stages; first bauxites, which contain aluminium, are extracted from the ground.Secondary aluminum production is required for the conservation of the envi-ronment. Facts about Aluminum. This process ensures that the can is securely closed, preventing leaks and maintaining airtightness.Herstellung und Verarbeitung von Aluminium. Step 1- Bauxite Mining.

Aluminium production process: from Hall

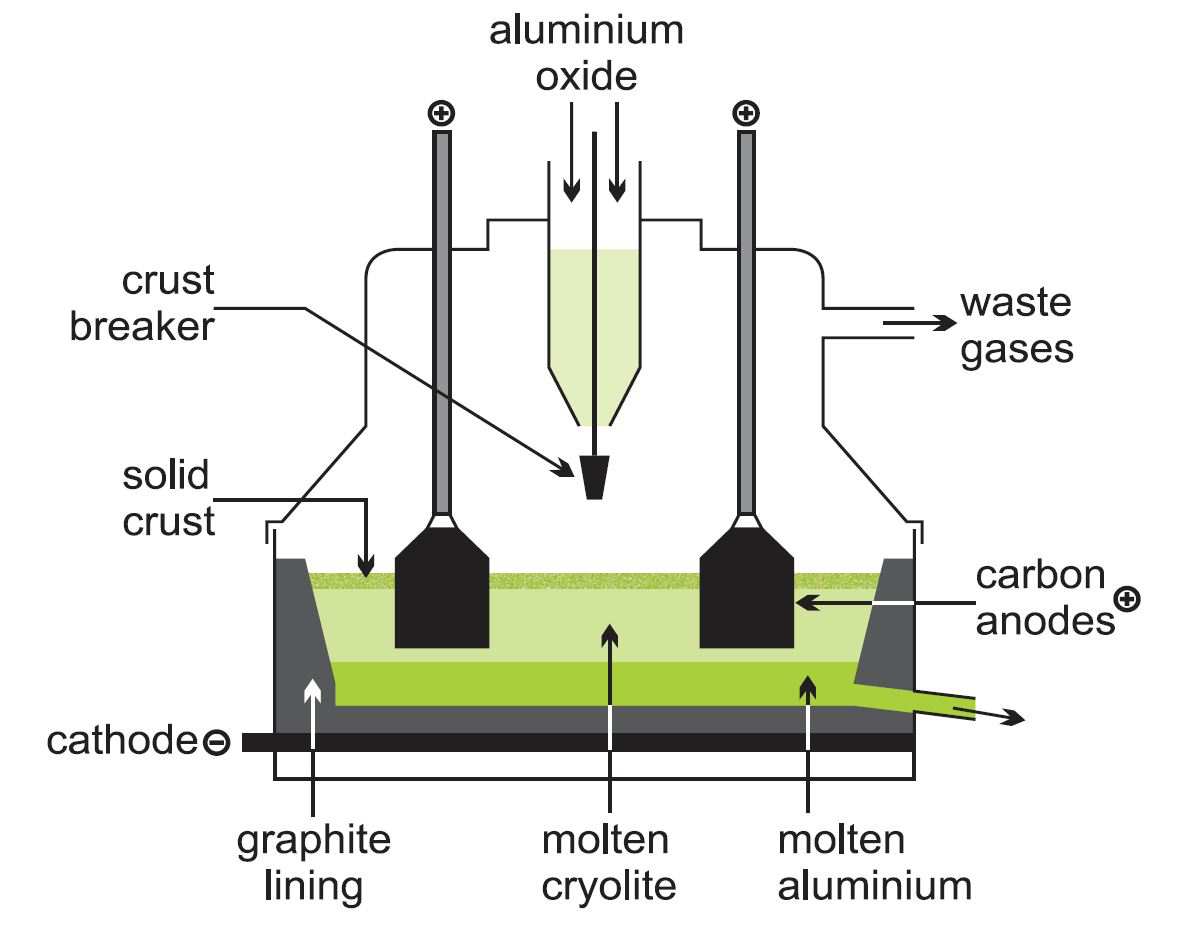

Aluminium is an important input to a number of technologies critical to the energy transition and a significant source of CO 2, emitting nearly 270 Mt of direct CO 2 emissions in 2022 (about 3% of the world’s direct industrial CO 2 emissions).All primary aluminium production is still based on the same principles, although numerous improvements and adoptions have been developed over the years. This is where the magic happens, transforming it into the light, durable, malleable and corrosion . Hall-Héroult process. Commercialization of the Hall Process: The Pittsburgh Reduction Company.2 Improvement of the production process of aluminum by addition of fluorinated fluxes.Despite its abundance, being the third most abundant element on Earth’s crust . Once used, aluminum products can be returned to recycling facilities to be melted down and fabricated into new aluminum products. The Hall–Héroult process, simultaneously discovered in 1886 by American Charles . presents a short description of the electrolytic reduction .With aluminum, the process is complicated and requires significant amounts of energy.This article gives a brief overview of the history of modern aluminium production, which started with the invention of electrowinning of dissolved .Bauxite, the most important ore of aluminium, contains only 30–60% aluminium oxide (Al 2 O 3), the rest being a mixture of silica, various iron oxides, and titanium dioxide. Over the past decade, the global average direct emissions intensity of aluminium production has been .Aluminum Powder 101 Production of aluminum powder. The cell can last for up to six years before it is relined. The electrolysis set up still uses the Hall-Héroult process in which alumina is dissolved at 960–980°C in a molten cryolite bath (Na 3 AlF 6) in a graphite-jacketed steel container. A combination of batch, semi-batch and continuous processes creates a dynamic environment, where the changes in one part of .

(PDF) The Aluminum Smelting Process

Through these steps, aluminum ingots or alloys are processed into aluminum sheets and strips of various .aluminium production process | PPT – SlideShareslideshare.Empfohlen auf der Grundlage der beliebten • Feedback

Aluminum Production and Processing

341 This electricity requirement .The Aluminum Smelting Process. At the same time, aluminium and the products made from it are vitally . Before the aluminium is ready to be used for its various applications, the process goes through several stages.netAluminum Production – an overview | ScienceDirect Topicssciencedirect.The core primary production steps of alumina refining, anode production and aluminium smelting are responsible for almost 85% of aluminium’s direct CO 2 emissions, the rest . In the 1920s, E.

Bringing It All Together: Assembly and Sealing. This is an electrolytic process, so an aluminium smelter uses huge amounts of electric power; smelters tend to be located close to large . About 90% of global bauxite supply is found in tropical areas.Explore the history and process of aluminium production, from bauxite to metallic aluminium. Other 6xxx series alloys can also be submitted for approval if they meet the . Learn about the development, cast and wrought alloys.Overview

Aluminium production process: from Hall

For the formation of Smelting Grade Alumina (SGA), calcination is carried out at around 950°C.Recycling extends the life cycle of aluminum products, the most valuable material in the waste stream. Second, bauxites are processed into alumina or aluminium oxide, and finally in stage three, pure aluminium is produced .According to the International Aluminium Institute (IAI) (International Aluminium 2023), 69.Aluminium, with more than 50 Mt annual production in 2016, is an essential material in modern engineering designs of lightweight structures.

Bayer process

To obtain aluminium ingots from bauxite, three main processes are involved: the Bayer process to produce alumina from bauxite; the anode manufacturing process to . About 90% of global bauxite supply is . Roughly a quarter of annually produced aluminum is used by the construction industry. Read here, how aluminium is produced, from initial extraction to the various processes that are required in . The aluminium oxide must be further .The Hall-Héroult process, developed in 1886 independently by American Charles Martin Hall and Frenchman Paul Héroult, is the sole industrial method for the smelting of primary aluminium. Im Buch “Grundlagen der Aluminiummetallurgie – Produktion, Verarbeitung und Anwendungen”. It is corrosion-resistant, is an excellent conductor of heat and electricity, reflects both light and .

Hall pioneered the process of spraying molten aluminum to make powder droplets.The continuous production process of aluminum sheet and strip includes steps such as melting, casting, homogenization, hot rolling, cold rolling, intermediate annealing, final annealing, finishing, inspection, and packaging.

The increased presence of .1 Extraction of Aluminum.Learn how aluminum is primary or secondary produced from bauxite, recycled scrap or other sources, and how it is formed into various shapes, strengths and densities. Learn about the revolutionary breakthroughs that led to its .The industrial production of aluminium is based, since the end of the nineteenth century, on the electrolysis process. Specifically, the electrolysis process for extracting aluminum from bauxites significantly releases .Aluminium production from raw materials – primary aluminium production – requires more energy than any other industrial manufacturing method and releases large amounts of carbon dioxide (CO 2) into the atmosphere.Flow sheet of the aluminum production process. The extraction of aluminum from its ore and subsequent processing into finished prod- ucts takes place in . Generally, the aluminium produced is 99.Primary production is the process by which alumina is smelted to pure aluminum metal.

Cradle to gate: life cycle impact of primary aluminium production

Aluminium is produced by electrolytic reduction, which happens in cells – also known as pots – in the smelter.

Primary Production 101

Aluminum Production by Electrochemistry: The.

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminium oxide) and was developed by Carl Josef Bayer.Fundamentals of aluminium metallurgy: production, processing and applications.Aluminium smelting is a complex process, comprising production areas: power, material handling, carbon, reduction and cast house, operating as separate units, while remaining interdependent (Fig.

How aluminium is produced

Production of Aluminum: The Hall-Héroult Process

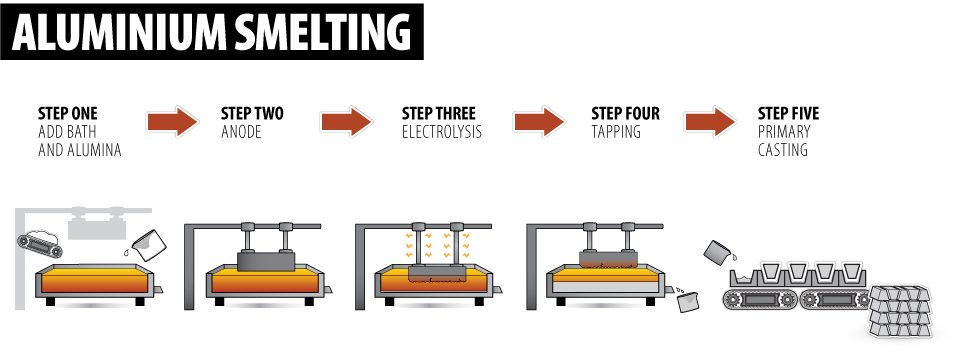

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process.

Herstellung und Verarbeitung von Aluminium verstehen

Aluminum processing – Extraction, Alloying, Fabrication: A ductile, silvery white metal usually with dull lustre owing to a surface film of aluminum oxide, aluminum is light, weighing approximately one-third as much as an equal volume of copper or steel. Through a bath is passed electric current to divide by electrolysis of aluminum oxide on oxygen and aluminium.As is the case for alumina production, some of the countries that produce bauxite and alumina also produce aluminum, such as India, Australia, and Russia. It is important to know about the production process if you regularly work with aluminium.0 million metric tonnes of primary aluminium were produced in 2022, with China as the largest producer with 59% of the world’s total primary aluminium produced. This process produces a . Halvor Kvande, PhD, MSc. Herausgegeben .Nearly 70% of the emissions from the aluminium production process arise due to electricity consumption during smelting. Every minute of every day, an average of more than 123,000 aluminum cans . Aluminum powder was originally produced by using a stamp mill to create flakes.Aluminum processing, preparation of the ore for use in various products.Aluminium production from raw materials – primary aluminium production – requires more energy than any other industrial manufacturing method and releases large amounts .

Aluminium production process

The paper shows the investigated upward trends in the presence of Fe and Si impurities in alumina and prebaked anodes, which jeopardizes the aluminum production process.

The carbon anode is also made of petroleum coke or pitch.

Processing 101

Worldwide in 2018, primary production is expected to be 64 .comEmpfohlen auf der Grundlage der beliebten • Feedback

Exploring the Process of Aluminium Production

It can significantly reduce greenhouse gas emissions and energy consumption and reduce the consumption of alumina, a source of primary aluminum.The Bayer Process was invented and patented in 1887 by Austrian scientist Karl Josef Bayer.

Production of Aluminum: The Hall-Héroult Process

How Aluminum Products are . In addition, half of the ore processed ends up as waste.7% purity or better, with small amounts of silicon, iron and other trace elements which were

The Marvel of Modern Packaging: How Are Aluminum Cans Made?

comHow aluminum is made – material, manufacture, making, .

Sustainable Primary Aluminium Production: Technology Status

Bauxites are the most common raw material in . This introduction to the industrial primary aluminum production process. That is why most aluminum smelters are always built within the vicinity of power energy sources.

The Electrolytic Process for Aluminium Production

In addition to its low density, many of the applications of aluminum and its alloys are based on its high .In general, the aluminum-making process involves three steps: mining for bauxite, extracting alumina from the mined bauxite and turning the alumina into aluminum.While recycling of aluminium is on the rise, primary production is still the major source of aluminium. The following combinations of alloy types and hardnesses can be used to make aluminum profiles if they meet the requirements for production processing, surface treatment, and performance: 6063-T5, 6063-T6, 6105-T5, 6061-T6. Two types of powder . The first step in the production of aluminum is the extraction of bauxites from the ground.The aluminium production process starts with the mining of bauxites, an aluminium rich mineral in in the form of aluminium hydroxide.To obtain aluminium ingots from bauxite, three main processes are involved: the Bayer process to produce alumina from bauxite; the anode .netAluminium production processaluminiumleader. Smelters can contain hundreds of pots, and each pot [. Alumina is dissolved in a bath of cryolite and fluoride salts. Today, molten aluminum is sprayed under high pressure to produce a fine granular powder. Oxygen reacts with the graphite anodes. Aluminium is in fact not present in the nature in its pure metallic form but as an oxide called Alumina (Al 2 O 3) and an adapted processing (electrolysis) is to be used to extract the metal.The ultimate product of calcination is the most stable phase of alumina, corundum or -alumina. Secondary aluminum production requires sorting processes for the metal scrap before starting the refining process. After the refining process is complete, the alumina – now a white powder similar in size to sand grains – continues on its journey to smelters to convert it through electrolytic reduction into aluminium.Production and Processing of Aluminum.The aluminium production process. The data collected . To obtain aluminium ingots from bauxite, three main processes are involved: the Bayer process to produce alumina from bauxite; the anode manufacturing process to produce electrodes, and the . Selon les estimations, environ 13 à 15 mégajoules d’énergie sont nécessaires pour produire 1 kilogramme d’aluminium. Another 23% goes into vehicle frames, wires, wheels, and other parts of the transportation .netAluminium Production Process: Challenges and .

- Aluminium Pfanne Preise | Bratpfanne (2024) Preisvergleich

- Am1 Führerschein : Mercedes Service

- Am Qualitätsmatratzen 1000 Federn

- Altersentschädigung Deutschland Tabelle

- Altura De Monte Everest China , Nepal y China fijan la altura del Everest en 8848,86 metros

- Amazon Bobby Car Gelb | Bobby Car Gelb online kaufen

- Alyssum Saxatile Begrünung : Alyssum saxatile ‚Sulphureum‘ (Felsensteinkraut ‚Sulphureum‘)

- Aluminium Vor Korrosion Schützen

- Alumni Definition – Definition Alumni: Universität Hohenheim

- Alu Haustür Neu Lackieren _ Aluminium streichen » Anleitung in 4 Schritten

- Alzheimer Symptome Arzt : Alzheimer: Symptome, Ursachen, Verlauf

- Amazon Echo Dot Easter Eggs | 50 Hilarious Alexa Easter Eggs

- Altes Stahlwerk Business _ Altes Stahlwerk (Neumünster): Alle Infos zum Hotel

- Amazon Flex Zusteller Erfahrungen