Data Driven Factories Of The Future

Di: Luke

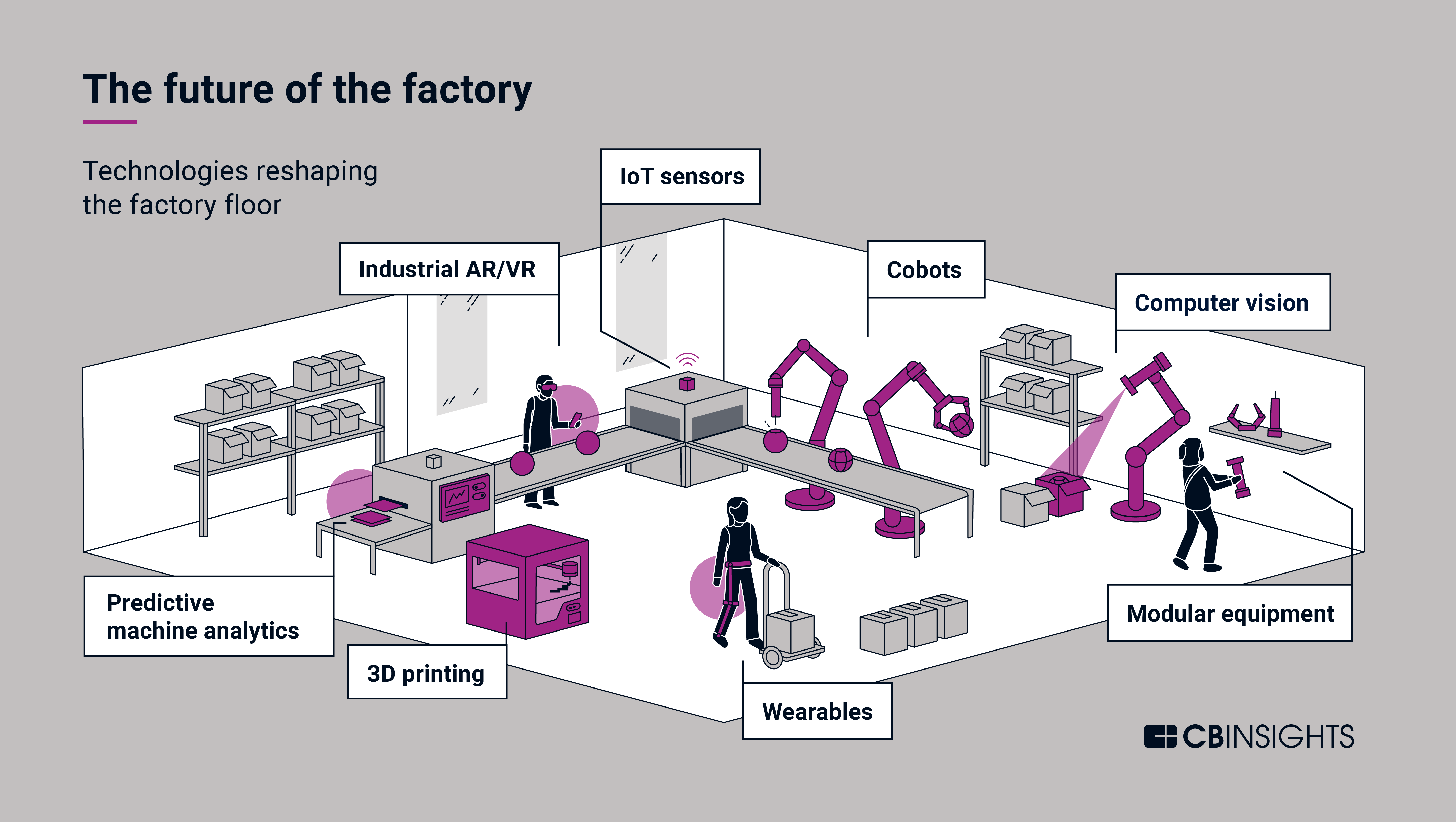

The 10 Biggest Future Trends In Manufacturing

The digitalization of a factory is deeply impacted by the new trends emerging under the umbrella of programs developed in the on-going fourth industrial revolution, which aims to automatize traditional manufacturing process and systems, taking benefits from the modern technologies developed by the ICT.

THE FACTORY OF THE FUTURE

Factory of the Future

Networking in the context of Industry 4. Technology and customer needs continue pushing .0 and China 2025. The deployment and validation of the architecture is being addressed within BOOST4. The Defense Counterintelligence and Security Agency’s new director wants to get DCSA’s critical next-generation background . Five of his suggested characteristics of the factory of the future are given below. We introduce a holistic Digital Twin approach, in which the factory is not represented by a set of separated Digital Twins but by a comprehensive .0 as organizations look to provide real time, .

Factories of the Future Awards 2024

(PDF) Big Data Analysis of Manufacturing Processes – .Partnerships Help Customers Successfully Navigate a Data-Driven World. But in most cases, talk has yet to turn into action. Cyber–physical production systems. The presented study highlights different trends for the realization of factories of the future, which involves applications of multiple technologies at different . We propose a framework for data-driven digital twin for smart factory, shown in Fig. March 6, 2021 • 13 MIN READ.Key elements of the Factory of the Future Quickly adapt manufacturing process to meet customers’ changing demands Flexible production Customer-centric plants: Personalized . Di Dai, Public Engagement, World Economic Forum, 中文. From high above the factory floor, I stood on a skywalk, watching the process from various vantage points. Data is processed and delivered in real time. Figures & data.Factories of the future: challenges and leading innovations in intelligent manufacturing. BUZ: Working together on the production of tomorrow.April 19, 2024 11:45 am.As a result, today, more than ever, manufacturers face the .0 EU project, focusing .2 Framework for Data-Driven Digital Twins. Trend 6: Automation and dark factories. Thanks to AI, machines are now capable of carrying out .Minimal breakdowns: AI-driven predictive maintenance systems use data from sensors and IoT data to pinpoint the exact location of maintenance requirements — saving technicians significant . It will help European industry to meet increasing global consumer demand for greener, more customised and higher .The ‘Factories of the Future’ programme aims at helping EU manufacturing enterprises, in particular SMEs, to adapt to global competitive pressures by developing the necessary key enabling technologies across a broad range of sectors. , Ricardo Jardim-Goncalves. · The World Economic Forum announces 21 new members of the Global Lighthouse Network, a community of manufacturers that . A Driving Force for Production: Logistics and Factories of the Future. At its core, DDS signifies that data, rather than traditional code, takes a central role in defining software behavior.7 trillion in value to global manufacturing. Digitalization.AI-driven factories of the future. April 17, 2024. Conecta con miles de clientes potenciales con una presencia que te permitirá .The manufacturing industry has been discussing factories of the future for a long time.netData Science in Manufacturing: An Overviewopendatascience. Dai Di, Public Engagement, World Economic Forum, .A comparison among the major trends in the digitalization of a Factory of the Future, in conjunction with the two major strategic programs of Industry 4. Put simply, “a smart factory is a connected factory,” says Simon Keogh, General Manager, Factory Automation at Siemens Digital Industries. Big Data is a statistical instrument with potential to improve world’s operations, increase its speed, make more intelligent decisions, and, consequently, forecast the future.The “Factory of the Future” concept is an idea that goes beyond conventional production paradigms and into a world where data is just as important as .A data driven hybrid cloud approach.

Reach your factory’s full . Factory operators know the best flow across the organization, so their input and engagement in designing the technology are integral for successful deployment. Pages 1-3 | Published online: 21 Nov 2016.Basic data-input and -processing skills will be particularly affected by automation, falling by 19 percent in the United States and by 23 percent in Europe in the 2016 to 2030 period.Thoughtful choices in technology adoption are necessary to improve resilience, reduce risk and lower costs. Cite this article. Decentralized system.

Big data analytics for smart factories of the future

Like the rest of the world, the factory is rapidly becoming more interconnected. With data-enabled technology platforms, the .Today BSH is one of the world’s leading home appliance manufacturers with around 37 factories worldwide and a network of about 80 sales, production, and service companies . The technological .In this paper, we address those limitations and propose innovations for cognitive modeling and co-simulation which may unleash novel uses of Digital Twins in Factories of the Future.The following are the seven characteristics of the data-driven enterprise: Data is embedded in every decision, interaction, and process.Obtén un reconocimiento con los Factories of the Future Awards de #AF2020. A couple of years ago, I toured the Ford Rouge Complex in Michigan, where the F-150 trucks are assembled. Fifteen new manufacturing sites join the World Economic Forum’s Global Lighthouse .

conjunction with the two major strategic programs of Industry 4.Data-Driven Operations Are Key to Future of Manufacturing. The rise of The inTelligenT facTory.Autor: Manu Suvarna, Ken Shaun Yap, Wentao Yang, Jun Li, Yen Ting Ng, Xiaonan Wang

Big data analytics for smart factories of the future

AI-driven factories of the future: the transcript. The smart factory, which is the real-world entity that is being modeled continuously produces data through the IoT devices and sensors. By Thomas Dewey.

Data-Driven Operations Are Key to Future of Manufacturing

The data-driven enterprise of 2025

While these areas did not particularly overlap in the past, the full integration of IT and OT will create unique insights generated from plant and operations data.World has turned into data-driven society.Factory of the Future. Modifications and readjustments, at whatever stage of the value and supply chain, are then possible in real time. As the rest of our .We asked Rasmus Hasle, who is the project manager at DTI, if he would draw a picture of what factories will look like if you go a handful of years into the future – and what role people will play.Understanding Data-Defined Software. In the modern business environment, the .It is essential to know how to operate and use the data .Factories embracing a data-driven and AI-optimised future. This data is the starting point of the data-driven modeling approach. August 17, 2018 After a decade of flat productivity, the arrival of the Fourth Industrial Revolution (4IR) is expected to create up to $3.Achieving the data-driven, lights-out factory of the future.Helena Leurent. Smart Factory: How digital is the factory of the future? The vision of the future for many entrepreneurs: the smart factory whose production organizes itself.An interconnected network of machines, communication mechanisms, and computing power, the smart factory is a cyber-physical system that uses advanced technologies such as artificial intelligence (AI) and machine learning to analyze data, drive automated processes, and learn as it goes. These traits describe factories of the future—and the people who lead them.

The factory of the future will be data-driven and AI-optimised

Logistics proves more and more to be the driving force for production – .The European Factories of the Future Research Association (EFFRA) is a non-for-profit, industry-driven association promoting the development of new and innovative production technologies. & Antonio Grilo. Nowadays humanity produces twice as much data as through all the time till 2007. “You have complete data flow and integrated workflows from raw . Data is revolutionising . In this paper, we . Sobre AF Ediciones anteriores Datos Industria 4. Only a small portion of companies are not planning to make their factories digital at all (9%). The vision: a data-driven factory of the future.Software driven facilities (also known as smart or digital facilities) combine a variety of modern technologies and IT systems which connect to each other, to create self-adapting and automated processes.

Smart Factory: the factory of the future

by Karl Fahrbach. reports a comparison among the major trends in the digitalization of a Factory of the Future, in.

Developing Smart Factories of the Future With Digital Twins

Just 39% of manufacturing executives report that they have successfully scaled data . In the factory of the future, data sharing occurs across a complex network of machines, parts, products, and value chain participants, including machinery providers and logistics companies.Smart manufacturing. Factory workers and management from all around the world came together to map out the company’s path for the future (see Nokia: The Conscious Factory – supply chain management of the future, page 14). EFFRA has been representing the private side of the manufacturing partnership with the EU Commission. How Digital Twins Can Drive Factories Of The Future. Descubre lo último en automatización industrial, robótica y tecnologías para transformar tu negocio.of collaborative approach.Wednesday, April 4th, 2018. Digitising the factory and delivering an Industry 4. An impressive serpentine system moved the trucks to each assembly station. Željko Pazin, EFFRA.

0 then leads to the “factory of the future” with data-based production, autonomous cyber-physical produc-tion systems – and integrated intelligence. Digital manufacturing tools and techniques, including artificial . These facilities are entirely interconnected by sensors and IT systems, collecting data and outputting it in software. So far, just 44 .Intel is empowering manufacturers to thrive as factories of the future, driven by data and ready for any demand.To meet these demands, a shift in the conventional paradigm is needed. Industrial Internet of Things. October 1, 2021 • 5 MIN READ. Named under Horizon 2020, Factories of the .

“Chatty Factories” is a concept that explores the transformative potential of placing IoT-enabled data-driven systems at the core of design and manufacturing processes, aligned to the Industry .Digital leadership, Tech-Augmented Workforce, Data-Driven Maintenance, and Zero-Touch Production are four of the cornerstone areas of building your Factory of . From factory planning and production to logistics and .Speaking to Siemens’ Simon Keogh, we look at the future of smart factories and the role digital twins will play in this. Smart and sustainable. CONCLUSIONS AND FUTURE WORK This paper proposes a data-driven architecture for Industry 4.

AI-driven factories of the future: the transcript

Digital and dynamic. Previously, I summarized a podcast about AI .Data driven and lights-out processes are key factors for optimizing manufacturing toward the factory of the future. Data analytics. The concept of a “lights-out” . A few years back, experts noted that the changes associated with the 4IR would come at an unprecedented rate yielding . The future of manufacturing is powered by data and analytics.0 and China 2025 is reported, which consists of the comparison between Digital Factory, Virtual Factory, Smart Manufacturing, and Cloud Manufacturing. The decline will be in nearly all sectors as machines increasingly take over straightforward data-input tasks. The world of manufacturing is .However, it will not deliver across-the-board benefits; for certain digital applications in the factory of the future, GenAI is less suitable or offers a less favorable ROI than traditional ML/DL-based AI, which includes creating transparency through data manipulation and visualization, detecting anomalies, analyzing production, optimizing .comEmpfohlen auf der Grundlage der beliebten • Feedback

Cyber

As SKF looked for a solution that supported their data-driven manufacturing vision for the Factories of the Future, they .As more of the world extends into the metaverse, more opportunities will arise for manufacturers. The need for most physical and manual skills will .Connecting the worlds of information technology (IT) and operations technology (OT) will do the trick to build the factory of the future.

The Fourth Industrial Revolution and the factories of the future

For many years it has been a production .This paper discusses essential elements of and promising solutions enabled by data science that are critical to processing data of high volume, velocity, variety, and . By Arash Ghazanfari, CTO (UK), Dell Technologies. Smart factories and smart manufacturing are part of the .0 roadmap allows an operator to realise vast improvements, efficiencies and consistency, says Adrian Champion, director of Jakarta-based Adhinata Consulting, which provides IIoT technology and engineering .Data-driven technologies including artificial intelligence and robotics are poised to transform manufacturing—but the rise of smart factories requires moving computing to the edge.0, using a containerized swarm approach to enable distributed processing and integration of all needed processing technologies.The evolution of data-driven autonomous systems and machine learning tools supports the promise of Industry 4.With the prevalence of sensor-rich machines and real-time data collection technology in modern smart production systems [3], data-driven lead time prediction is now feasible. Manufacturers are challenged to bring efficiencies to their factories and increase the quality of their products.

Factories embracing a data-driven and AI-optimised future

Advanced Manufacturing.

- Das Innere Kind Bedeutung _ Das innere Kind heilen: Warum Selbstliebe der Schlüssel dazu ist

- Data Protection Impact Assessment Guidelines

- Datentresor Windows 10 , Die besten Gratis-Datentresore

- Data Security Checklist : Data Security Risk Assessment Checklist

- Datev Führerschein In Deutschland

- Datev Paumgartnerstraße 6 14 _ DATEV nachhaltig auf Wachstumskurs

- Data Processing Life Cycle Diagram

- Datenschutz Medizin – Datenschutzrecht

- Datenart 11 | Was sind alle Arten von statistischen Daten? (Beispiele)

- Datev Aktuelle Version Download

- Dating Sims Online – The best dating sims, ranked

- Das Schlagzeug : Schlaginstrumente: Übersicht, Definition, Geschichte

- Das Erste Autoradio : Wann wurde das Autoradio erfunden?

- Datei Mit Link Verbinden Windows 11

- Dasteigichein Busfahrer , 18 Jobs als Busfahrer, Busfahrerin in Göttingen