Desktop Metal Production System

Di: Luke

The fine feature resolution of the Shop System allowed for easy printing of the male thread, just requiring a quick chase to clean up the profile after sintering.These complex demonstration parts are binder jet 3D printed on the Desktop Metal Production System™ P-1 in C18150, also known as chromium zirconium copper.76 Parts/build*: 319 Parts/week:* 2,499. Studio System™ oder Studio System™ + können ohne weiteres aufgerüstet werden.Video ansehen1:17Desktop Metal. The Pennsylvania-based FreeFORM is also slated to take delivery of a Production System .Desktop Metal® Exists to Deliver on the Vision of 3D Printing: Mass Production.

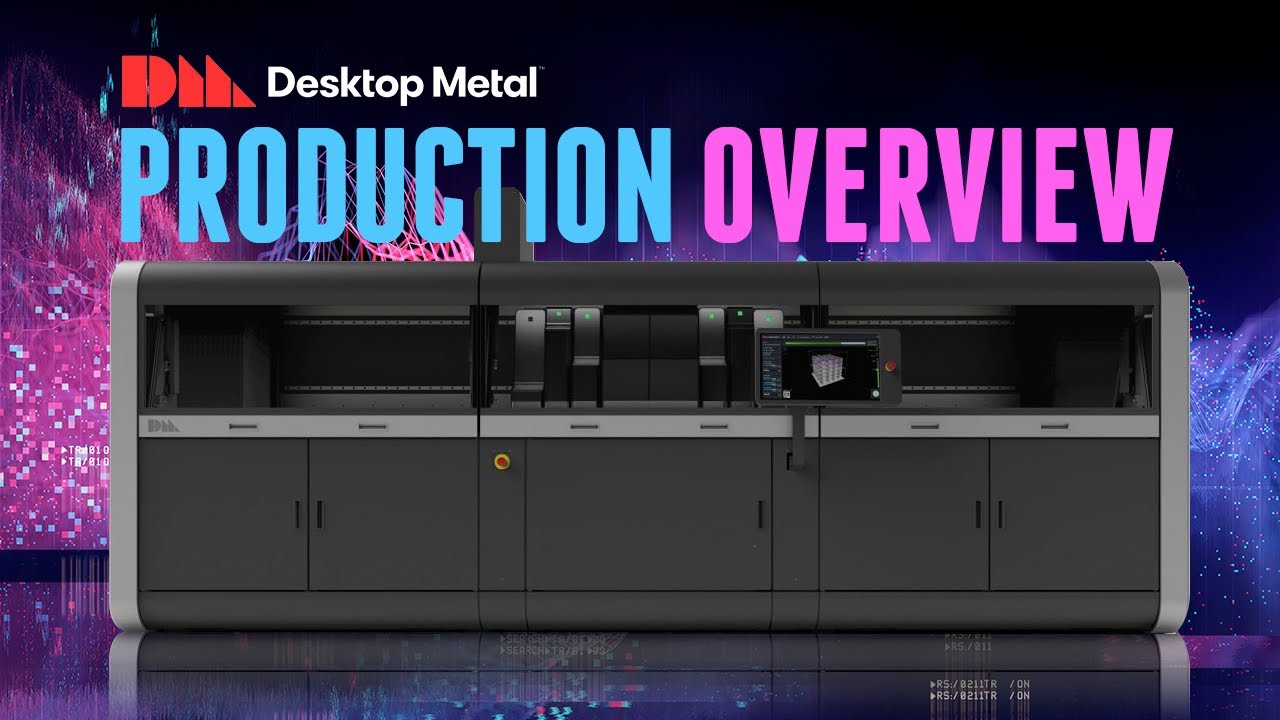

Introducing the Production System™ P-50

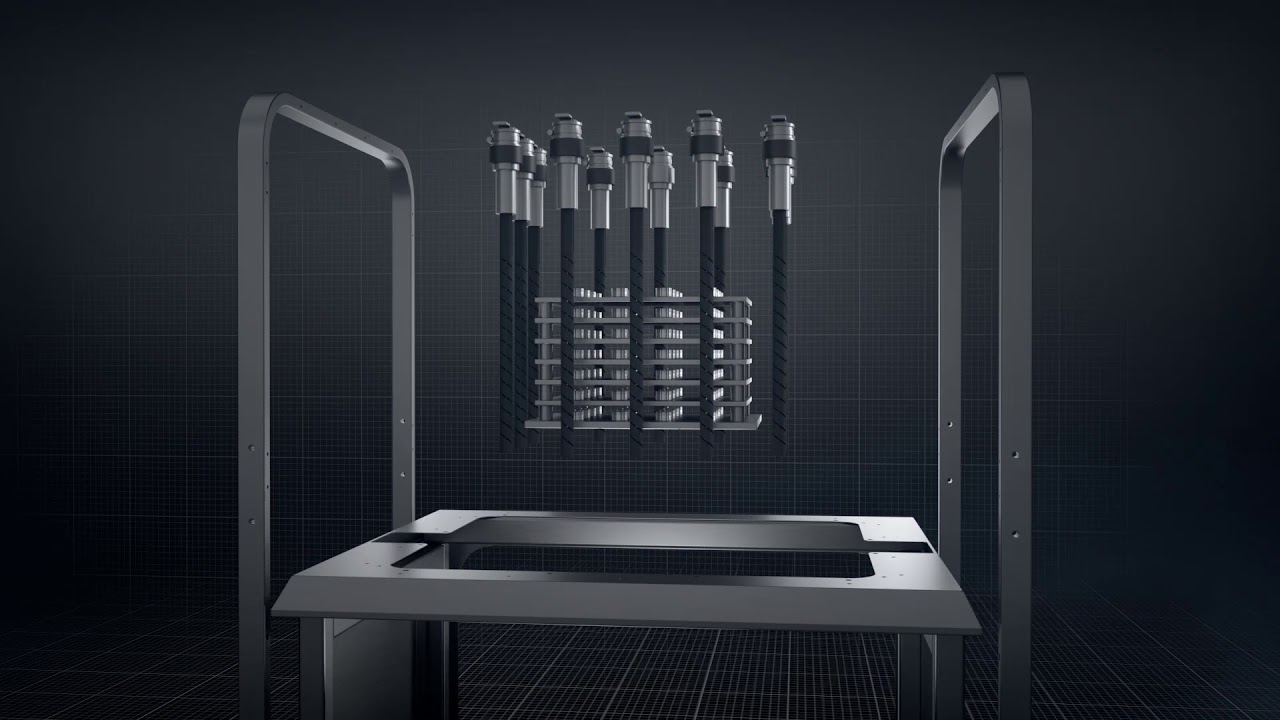

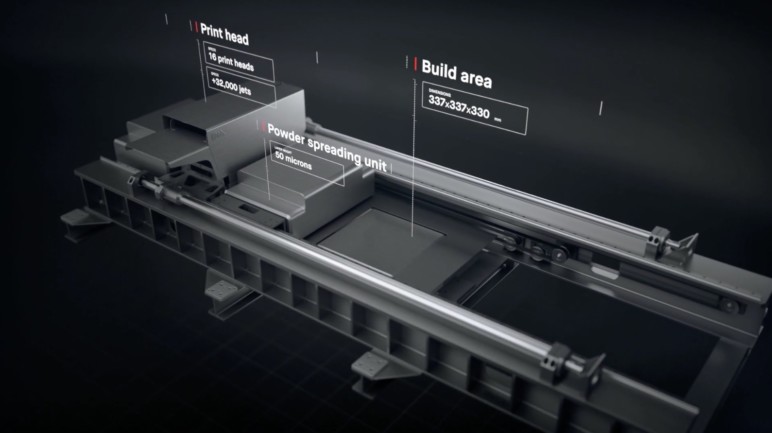

Created by the inventors of binder jetting and single-pass inkjet technology, the Production System is an industrial manufacturing platform powered by Desktop Metal’s Single Pass Jetting TM technology.Desktop Metal® AISI 316L / 1. The Production System uses Desktop Metal’s Single Pass Jetting™ technology, to produce metal parts with economies of scale . For the full year, DM reported record recurring revenue of $65 million, a 29% increase over the prior year that now represents . Production System™ Production System™ Metal.As one of the .The installation of the first Production System is scheduled for Q1 2019 to a Fortune 500 company among Desktop Metal’s early Pioneer customers. Vorteile: 01 ausgezeichnete . Shop System™ Shop .Productionシステムは、サードパーティ製の金属粉末を使用することが可能となります。.4404 (Production System™) Metall Edelstahl 316L zeichnet sich durch seine Korrosionsbeständigkeit und seine Leistungsfähigkeit bei hohen und niedrigen Temperaturen aus und ist ein vollständig austenitischer Stahl, der sich ideal für raue Umgebungen eignet. Powered by single-pass binder .At Desktop Metal, we’re leading the way with two print-and-sinter metal 3D printing technologies that prioritize ease-of-adoption and pair with the Desktop Metal Furnace for a production-ready process. *Costing and Throughput for 16L Shop System without Setters.Das Studio System™ 2 von Desktop Metal® nutzt die extrusionsbasierte Drucktechnologie und kombiniert durch das nachgelagerte Sinterverfahren die „Fused Filament Fabrication“-Technologie (FFF) mit dem Metallspritzguss (MIM).Desktop Metal® Ag (Production System™) Silber, ein wertvolles Metall, hat das höchste elektrische, thermische und Reflexionsvermögen aller Metalle und wird häufig wegen . As one of the most highly anticipated additive manufacturing systems ever introduced, the P-50 is the product of nearly $100 million in . X-Series X-Series Metal and Ceramics.BOSTON–(BUSINESS WIRE)– Desktop Metal (NYSE:DM), a leader in mass production and turnkey additive manufacturing solutions, today announced it has qualified the use of titanium alloy Ti-6Al-4V (Ti64) for the Studio System 2™, an accessible metal 3D printing platform that offers customers the easiest way to print high-performance metal parts . We’re investing in area-wide 3D printing platforms, . // Highspeed-Metall-3D-Druck für die Massenproduktion.Autor: Desktop Metal

X-Series

Desktop Metal has shipped its first Production System P-50 printer, marking the commercialization of the company’s flagship additive manufacturing . It integrates with the Studio System printer and furnace to reduce operator burden, ensure process efficiency, and automatically .The Production System – the World’s Fastest Way to 3D Print Metal Parts At-Scale.

Desktop Metal® Studio System™ 2

Desktop Metal has shipped its first Production System P-50 printer, marking the commercialization of the company’s flagship additive manufacturing technology for mass production of end-use, metal parts.71K subscribers. 10K views 1 year ago.Desktop Metal’s print and sinter process, combined with next-generation Separable Supports™ and a software-controlled workflow, makes metal 3D printing simpler than ever.BOSTON– (BUSINESS WIRE)– Desktop Metal (NYSE:DM), a leader in mass production and turnkey additive manufacturing solutions, today announced it has qualified the use of .

[i] Designed as an end-to-end solution, the Studio System is the . Download our system overview to .comEmpfohlen auf der Grundlage der beliebten • Feedback

Introduction to the Production System P-50

Production System P-50. Introducing the Production System P-50, Desktop Metal’s flagship additive manufacturing technology for mass .

The Desktop Metal P-1 and P-50 Production 3D Printers are the first metal additive manufacturing systems designed for mass production. Fertigen Sie schnell und .Systems Overview. Designed to serve as a bridge from process development to full-scale . We exist to deliver Additive Manufacturing AM 2.

Desktop Metal® Shop System™

Desktop Metal Opens New Manufacturing Facility

0 technologies, materials, and applications that enable mass production. Während das DM Studio System ein bürotaugliches Gerät für schnelles Prototyping ist, handelt es sich bei dem DM Production System um einen 3D-Drucker für die Serienfertigung von Metallteilen, der mit einer bis zu 100-fach schnelleren .

金属3Dプリンター Desktop Metal Production システム

Studio System: An end-to-end solution for metal 3D printing

Designed to be the fastest way to 3D print metal parts at-scale, the P-50 leverages Desktop Metal’s patent-pending Single Pass Jetting technology and bi-directional printing to achieve speeds up to 100 times those of laser powder bed fusion technologies⁴, producing parts in volumes and at costs competitive with conventional mass production .Das Desktop Metal® Shop System™ ist die optimale Anlage zum Produzieren von komplexen Metallteile in kleinen und mittleren Stückzahlen.Das Startup Desktop Metal aus den USA hat zwei neue 3D-Drucker für Metall vorgestellt.

The Studio System™ Brochure

_Desktop Metal. We are Team DM. Questa innovativa stampante 3D per acciaio di Desktop Metal è il sistema di produzione 3D che offre altissima qualità e costo per pezzo .

Binder jet 3D printing featuring patented Triple ACT for excellent surface quality and specialty materials, including both metals and ceramics. With no solvents, loose metal powder, or lasers, the Studio System is designed for hands-on use with minimal training and runs with little operator intervention.Powered by Single Pass Jettingätechnology, the Production System is the first and only metal 3D printing system for mass production that delivers the speed, quality, and cost . [3D PRINTING SYSTEMS] 01.Simplify metal 3D printing with the Desktop Metal Studio two-part solution including Live Studio software. Designed to be the fastest way to 3D print metal parts at-scale, the P-50 leverages Desktop Metal’s patent-pending Single Pass Jetting technology and bi-directional printing to achieve speeds up to 100 times those of laser powder bed fusion technologies⁴, producing parts in volumes and at costs competitive with conventional .Video ansehen1:17Introducing the Production System P-50, Desktop Metal’s flagship additive manufacturing technology for mass production of end-use, metal parts. It is designed to achieve speeds up to 100 times .Das Binder-Jetting-System mit offener Plattform ist ideal für die Serienproduktion kleiner, komplizierter Teile sowie für die Prozess- und Materialentwicklung.FRANKFURT, Germany– ( BUSINESS WIRE )–With preparations underway for the first customer installation of its mass production system in early 2019, .BOSTON–(BUSINESS WIRE)– Desktop Metal (NYSE: DM), a leader in mass production and turnkey additive manufacturing solutions, today announced the new P-1 printer has begun global shipments and joins the Production System™ lineup alongside the flagship P-50 printer., which was founded in 1984 and sold last year to Kymera . The company is a spin-off of AmeriTi Manufacturing Co. The Shop System’s unparalleled productivity – as much 70 kg of metal parts can be printed in a single day – allows it to deliver per-part .Leveraging Desktop Metal’s [patented] Single Pass Jetting™ technology, the Production System™ offers metal parts production with economics and reliability that enable going to market at scale with metal 3D printing.FreeFORM Technologies President Nate Higgins, shown in front of a Desktop Metal X25Pro, now operates the world’s largest fleet of 25 Desktop Metal binder jet 3D printers, which transform metal powder into complex end-use parts.Autor: Desktop Metal The most compact binder jet 3D printer for the production of metal, ceramic or composite parts. Production System™. The P-50 is designed to mass produce high-performance metal parts with the repeatability and cost required to compete with .4404 (Production System™) Metall Edelstahl 316L zeichnet sich durch seine Korrosionsbeständigkeit und seine Leistungsfähigkeit bei hohen und . High-speed mass production of metal parts, designed for the factory floor. High speed metal . The material has now been qualified for use on that high-speed printing platform in collaboration with Sandvik Additive Manufacturing, a world-leading producer of gas . _ The ExOne S-Max Flex robotic sand 3D printer.In addition to process and product innovations, exceptional productivity, print quality and reliability, the Shop System delivers another key benefit – the ability to both reduce costs and increase revenue. [ [Latch A]] Size: 60 x 14 x 10 mm Cost/part*: $5.

The Production System combines Desktop Metal engineered binders with an open material platform, allowing customers to produce high performance parts using .

Purchase a Production System™ and mass produce metal parts

Production System P-50 di Desktop Metal è la stampante 3D che stampa l’acciaio, oltre ad una vasta gamma di metalli, per produrre su larga scala parti in metallo grazie alla tecnologia additiva binder jetting.TriTech Titanium Parts LLC, which is ISO 9001:2015 certified, uses metal injection molding (MIM), investment casting, and now, binder jet 3D printing on the Desktop Metal Production System P-1 to produce titanium parts.The Production System’s™ inert environment, open material platform, and selection of Desktop Metal-engineered binders enable 3D printing with a wide variety of metals—including everything from stainless steels to reactive metals and . 造形実績のある材料としては、17-4PH、316L、4140、インコネル625、420ステンレス .Fulop noted that DM continues to see strong demand for production binder jet systems that produce metal, sand and ceramic parts, as well as increasing evidence of the value of Additive Manufacturing 2.Preiswerter Metall 3D-Druck in Büroumgebung! Das Studio System™ 2 von Desktop Metal® nutzt die extrusionsbasierte Drucktechnologie und kombiniert durch das nachgelagerte Sinterverfahren die „Fused Filament .

Studio System™

Das weltweit erste Metall-Binder-Jetting-System, das für Serienfertigung entwickelt wurde! Im Vergleich zu konventionellen Produktionsverfahren und der laserbasierten . Launched in 2018, this easy-to-use system features Triple ACT and a piezoelectric .Das Desktop Metal® Produktion System™ P-50 arbeitet bidirektional nach der patentierten Single Pass Jetting™ Technologie von Desktop Metal® und hat eine Druckrate von 12.The system is produced at Desktop Metal’s Polymer Center of Excellence in Richardson, Texas.

Desktop Metal Expands Its Production System Lineup With New Printer Designed to Bridge Process Development and Full-scale Metal Parts Mass Production. Priced for purchase at under $40,000, the ETEC Pro XL is a premium DLP printer with 385 nm wavelength technology, 5mW/cm 2 power, and Hyperprint™ closed-loop printing – all of which work together to deliver premium results at high .Purchase a Desktop Metal 3D printing system and get started printing metal and composite parts. Additional customer installations at major automotive, heavy duty and leading metal parts manufacturers will follow throughout 2019, with broad availability in 2020. Download our guide for an in-depth comparisons between the Shop System and Studio System metal 3D printers. Desktop Metal® .comWhy Desktop Metal Stock Got Destroyed Today | The . Desktop Metalからは、多種多様な材料種に対応可能な3種類のバインダーが供給されます。. Metal and composites 3D printing 3D printing solutions for health care Industrial-grade .

The Shop System: Reduce Costs, Increase Revenue

Die inerte Bauraumumgebung ermöglicht die Verarbeitung sowohl von reaktiven und nicht-reaktiven Metallen, die kostengünstig auf dem hiesigen .

Das Desktop Metal® Production System™ P-50 wurde von Pionieren der Binder-Jetting- und Single-Pass-Inkjet-Technologie entwickelt und ist derzeit das schnellste additive .By using anti-ballistic technology, print bar redundancy, and live optical bed inspection in this production system, Desktop Metal is able to offer robust repeatability.Designed as an end-to-end solution, the Studio System ™ leverages Bound Metal Deposition™ technology to print complex metal parts in-house. Built from the ground up, Live Studio enables a simple and seamless workflow from digital file to sintered part. 1, 2021 — Desktop Metal today announced the opening of a new in-house manufacturing facility that will more than triple the final assembly space currently .Desktop Metal Production System.Introduction to the Production System P-50.The Desktop Metal Production System P-50. This results in reducing powder bed disturbance, and the overall variability in the complete 3D printing process. Your browser does not support the video tag. Production SystemTM – 3D-Druck für die Industrie.Could Desktop Metal Be a $100 Stock in 5 Years?fool. Additionally, it also increases the longevity of the print bar.

- Designcad 2D 3D – DesignCAD V25

- Desertec 3.0 | Desertec reloaded: Wie Afrikas Wüstenstrom genutzt werden soll

- Dermaroller Set Kaufen : DERMAROLLER kaufen für Gesicht & Körper

- Detterbeck Öffentliches Recht : Öffentliches Recht

- Design Studium Köln – Grafikdesign und Visuelle Kommunikation (Bachelor)

- Detlef D Soost Kosten – Wer ist Detlef Soost: Steckbrief, Lebenslauf, Herkunft uvm

- Desert Tech Mdrx Se _ DESERT TECH MDR

- Der Tod Steht Ihr Gut Stream : Wer streamt Der Tod steht ihr gut? Film online schauen

- Desktop Hintergrund Microsoft Windows 11

- Derbi Occasion Deutschland , DERBI Occasion kaufen und verkaufen

- Detox Pflaster Füße Erfahrungen