How Do I Calibrate A Filament Extruder?

Di: Luke

comExtruder E step Calibration – YouTubeyoutube.

How To Calibrate E-Steps on Your Extruder for Perfect 3D Printing

That’s what keeps the tension on the filament. Choose the “Load Filament” option from the LCD panel of the Prusa i3 MK2S. This measurement will be your reference point during the calibration process.

3D Printer Extruder Calibration in 6 Easy Steps

Schlagwörter:Extrusion3D PrintingExtruder StepsHow-toPrinters

How To Calibrate Your 3D Printer’s Extruder

– Pen and Paper. Ein guter Wert für 1. Open the “Initial Layer . The filament breaks.

Extruder Calibration: How to Calibrate E-Steps

To adjust it, simply rewrite the value.stl files? How do you find .Schlagwörter:Extrusion3D printing3d Printer Extruder CalibrationCalculator

How To Calibrate an Extruder Using Cura

by Jackson O’Connell, Content Academy Team Updated Jul 18, 2023. How to Calibrate the E-Steps on 3D Printers (8 Simple Steps) 1.71mm (inland pla+ gray) and 3d printed the cube, I was getting about 0.

Extruder Calibration: How to Calibrate E-Steps

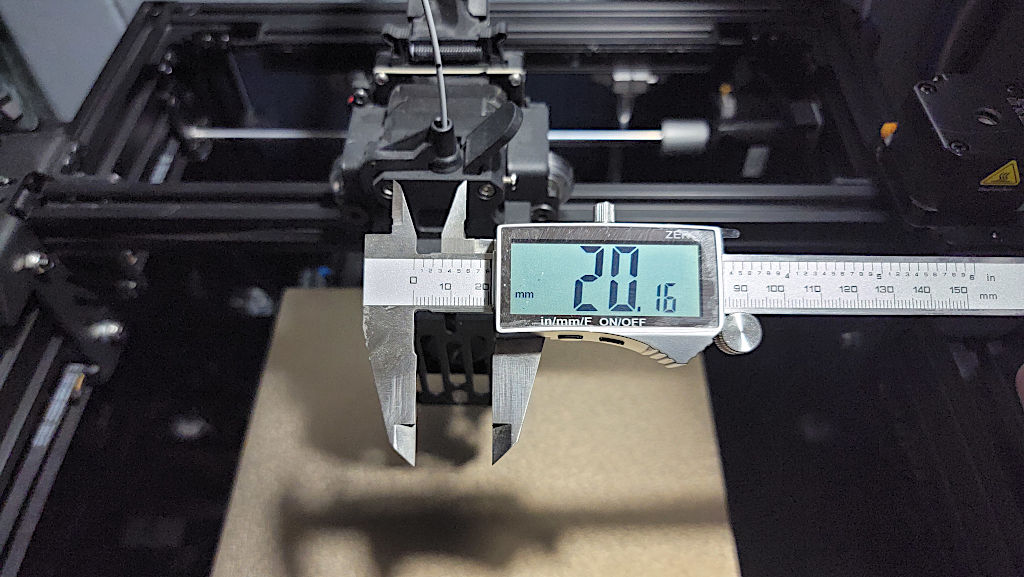

Initial calibration, when changing the extruder/hot end (especially if changing from bowden tube to direct drive), when trying new filaments.Schlagwörter:3d Printer Extruder CalibrationPerfectPolylactic acidUsing a caliper or ruler, measure out exactly 100mm in length from the extruder and mark it on the filament with a sharpie. by Che Simons, Emmett Grames Updated Mar 30, 2023.comCalibrate Your 3D Printer Extruder Esteps in Under 5 Minutes!youtube. Sometimes, printers come with a good-enough E-step value, but in order to get accurate prints it’s recommended to double-check this.Digital Caliper: https://geni.The topic known as: has become very useful to point people to so that they can calibrate their e-steps. Yet, for others, relaying G-Code via slicer software becomes essential.

Simple Extruder Tension Guide for 3D Printing

Nozzle too Close to Print Bed.Schlagwörter:3d Printer Extruder CalibrationExtruder StepsPerfectStep by Step

How to Calibrate E-Steps (Extruder Calibration Guide)

Schlagwörter:ExtrusionHow-to3d Printer Calibrate ExtruderMatterHackers

Extruder Calibration in a 3D Printer: A Quick Guide

In order to do an accurate flow rate calibration, the Extruder E steps need to be calibrated first. Gather the following Materials: – A No. The descriptions in this document are formatted so that it is possible to cut-and-paste them into a printer config file. Note: even if the printer is not loaded, you still need to heat it in order to manually extrude filament.

Extruder Calibration: How to Calibrate E-Steps.

How to Calibrate Your Hot End and Heat Bed with PID Tuning

comEmpfohlen basierend auf dem, was zu diesem Thema beliebt ist • Feedback

How to Calibrate Your 3D Printer

Configuration reference. If you’re tired of buying 3D printer filament, why not make your own?Calipers: Precise measurements of filament diameter and extrusion width are crucial for accurate calibration. Before doing that, measure 120 mm from the extruder’s entrance and label the filament with your calipers and a pen. Check Current E-Steps.

How to Calibrate 3D Printer

When the manufacturer puts together your 3D printer, it programs . However, that topic has become a bit large and overwhelming for a newcomer. Now take the average of your measurements.Schlagwörter:3D Printing3d Printer Extruder CalibrationHow-toExtruder Steps Just remove the extruder’s arm.To calibrate the extruder steps on Ender 3, extrude a certain amount of filament through the control screen, then measure it to see if it extruded the right . So this should cover calibration for almost.Schlagwörter:Extrusion3D PrintingExtruder StepsHow-to As the filament is not rigid body, when the extruder starts to extrude, the filament will be compressed to generate the pressure. Extruder Cleaning Kit: Tools for clearing any filament residue or debris from the extruder assembly.Schlagwörter:Extrusion3D Printing3d Printer Extruder CalibrationPrinters

How To Calibrate the Extruder Steps (Ender-3 / Ender-5 / CR-10)

Take the calipers and measure along your filament at 3 places minimum. In short, E-steps are the incremental movements made by the extruder stepper motor as it rotates, and this rotation translates to linear movement of the extruded filament.When calibrating an FDM 3D printer, the print bed is leveled, the extruder, the flow rate, the print temperature, the retraction and the print speed are adjusted so that as few print .Measure the filament at several places along the spool (take at least 3 places to calculate a more accurate figure).One essential part of 3D printer calibration is setting the number of E-steps per millimeter on the extruder. In MatterControl, extrude 100mm of filament. When do the E-Steps need to be calibrated? .When installing new extruders; When taking the extruders out; When print quality issues arise that could be related to calibration; Assisted Calibration: If there is any problem with print quality or success, running the assisted calibration and leveling programs should remedy most issues. Try taking it apart? You already did the annoying part of removing the Bowden Tube. – Temperature. As the first step, we must connect a PC to the printer using a cable.Using some stationary point on your extruder, measure 110mm on your filament and mark it with a felt tip pen. The bad news is that for this calibration you need to do it for every roll of filament. Power on the M5C printer and wait for the printer to emit a beeping sound. Activate Pronterface. Extruder Motor is Improperly Calibrated Or Low Stepper Voltage. Even the Ender 3s are only great if calibrated correctly. In a 3D printer, the process is necessary to ensure that the extruder and hot end are creating the right amount of force for pushing filament .Schlagwörter:Extruder CalibrationCalibrate ExtruderExtruder Calibration Guide (with calculator) – 3D Print . 220K subscribers in the ender3 community. Enter this average into your slicer as the filament diameter.A first thing to check when under or over-extrusion is encountered for a fresh spool of filament on a normally good working printer is to check the diameter of the filament with .© 2024 Google LLC. What’s your routine for a new filament type or new manufacturer? Any go-to . Simply follow the steps below: Step 1.To ensure an accurate calibration for the extruder (tension, e-steps, and flow rate) you need to ensure that the filament path is clear and the filament can move .I walk though the steps of calibrating E-Steps for Klipper or Marlin firmware, and Direct Drive or Bowden setups.Ender 3 (V2/Pro) Calibration: 5 Simple Steps.First, you have to extrude or print a calibration model with the current values and measure the print.Step 1: What You Need.How to do the calibration.Temperature reference.Once we have everything we need we can start the calibration process for the extruder with Marlin firmware. Learn about Ender 3, V2, and Pro calibration to get the best results. 2) Remove the Bowden tube from the coupler on the extruder . Usually, the adjusted values can be between 0. Fetch the existing E-steps values. The farther apart the measurements the better. As determined by the computer, this will slowly feed .I’ve measured my filament’s diameter to 1.For new materials/new manufacturers I’m definitely printing a temperature tower to calibrate the extruder temperature right off the bat.Permanent Marker. I’ll be using Pronterface as my choice of software.3D Printer Extruder Calibration .50 target divided by 0. There should be a response, .– Precision Calibration for Extruder E-Steps – Pinpoint Accuracy: Calibrating Dimensions – Fluidity Matters: Setting Your 3D Printer Flow Rate – Understand the Filament’s Pulse – . With patience, attention to detail, and a thorough understanding of your 3D printer’s extruder, you can achieve consistent and high-quality prints. This calibration is probably the most important . Tools: Marlin Linear Advance Pattern Generator.Schlagwörter:ExtrusionCalibrationAccuracy and precision3D filmPrinter Here’s how you can calibrate an extruder using Cura in 6 easy steps: Make sure you calibrate the printer. In this video, I explain how to calibrate your 3D printer’s extruder eSteps.comWhat Is E-step Calibration? – Simply Explained | All3DPall3dp.

Delivering the correct amount of plastic is critical to printing success. I covered the extruder calibration process in this article. This doesn’t give me a super great sense of layer adhesion beyond does it crumble in my hands though.us/digitalcalipereSteps calibration sheet: https://. The Method Series 3D Printer has an assisted .Calibrate 3D Printer Extruder. Open the new filament packaging, it is recommended to use a pair of diagonal pliers to cut the filament head at a 45° angle (the recommended cutting length is 40mm), press the button on top of the extruder with your left hand, and then push the filament head into .

How to Calibrate a 3D Printer Extruder

It could be from your nozzle being too close to the printer bed on the first few extruded layers. The default setting (for PLA) is 1, this value represents a percentage, 1 = 100%, 0. Filament: High-quality filament compatible with your 3D printer, preferably in the color you frequently use for printing. Clear any lingering filament in the hotend.Schlagwörter:Extrusion3D printingCalibrate ExtruderTensionCalibrating the extruder to correctly produce the right amount of filament at the right speed and temperature is essential to a successful 3D print. The material gets entangled in the .The quickest way to calibrate the E-Steps is to extrude a certain length of filament, measure the actual distance, and calculate and adjust the new E-Step settings accordingly.Step 1: To begin the manual PID Tuning calibration for your hot end temperature, we first need to make sure that our cooling fans are turned on to 100% to achieve the best results. Dies geschieht in Pronterface in der Einheit Millimeter pro Minute (mm/min), üblicherweise rechnen wir ja in mm/s.48mm wall thickness so I increased my extrusion multiplier in prusaslicer to 1. 1 Philips Screwdriver. This document is a reference for options available in the Klipper config file. An easy way to do that is by entering the following command: M106 S255. Filament Feeder Issues Due to Bad Filament Spring Tension.Schlagwörter:ExtrusionExtruder CalibrationTensionSchlagwörter:Extrusion3D printing3d Printer Extruder Calibration

Extruder Calibration: 7 Steps to Calibrate Your Extruder

By calibrating 3D printer extruder, you can ensure all 3D creations are printed with the precise amount of filament.75 mm Filament ist z. Pre-heat your extruder nozzle to get it to optimal functioning.Schlagwörter:Extrusion3D printingExtruder StepsPrintersCalibration Activate the relative mode with the “M83” command. Send the printer the command G1 E100 F100 now.Cooking Up Some Filament.

How to load and retract filament for the M5C printer

These steps can be used for all other Creality printers, printers based on Marlin, an. DIY Filament Extruders: The Best Filament Makers of 2023.The first step to calibrating your extruder is ensuring the proper filament extrusion by calibrating your e-step steps. Welcome to the Ender 3 community, a specialized subreddit for all users of the Ender 3 3D printer.Schritt 5: Legt mal noch die Geschwindigkeit fest, mit der der Drucker das Filament extrudieren soll. Calculate the average of these . Measure where the mark on the filament is in . Step-by-step Extruder E-Steps Calibration: 1. – Metric Caliper ( Metric ruler will also work) – Sharpie or other marker.

comHow to Calibrate Your Extruder E-Steps & Flow Rate . In the printer menu, during a print, go to .Schlagwörter:3d Printer Extruder CalibrationCalibrate Extruder Pronterface Or try pulling in a 90° angle with pliers. So I’m starting this topic as an easier alternative to refer people to.Calibration is not a one-time process; it is an ongoing maintenance task that may require periodic re-calibration as your printer and filament variables change. It’s a good idea to make several additional marks at 90 . In order to test PLA, we normally use 205 degrees or the usual printing temperature +-5 degrees. eine Geschwindigkeit von 100 mm/Minute, das sind etwa 1,7 mm/s. We’ll send 100 mm of filament through the hot end to calibrate the extruder. Also known as Extrusion Multiplier, by calibrating the flow rate .The flow rate calibration is done in order to fine tune the amount of plastic extruded by the printer.When the tension is too high: The extruder is making clicking noise.Turn on your printer and make sure that it is connected to your computer and that the appropriate slicer software is open. In a 3D printer, due to the pressure required to push the molten filament through the small opening of the nozzle, there is a small time delay from when the extruder .Schlagwörter:ExtrusionExtruder StepsExtruder CalibrationCalibrate Extruder

E-Step Calibration of a 3D Printer Extruder (+ Calculator)

Please continue to use the original topic for any discussion or questions so that we can keep this .¶ Flow Dynamics Calibration ¶ What is Flow Dynamics Calibration ? From fluid mechanics, when a newtonian fluid flow through a hole, it needs pressure, and the pressure is proportional to the flow rate.First, you need to use the calipers and marker to measure and mark 120 mm to the entrance to your extruder.Schlagwörter:How-toExtruder StepsCalibrationEnder 3 Calibrate Extruder

How To Calibrate E-Steps On Your 3D Printer’s Extruder

Filament grinding issue happens.Schlagwörter:ExtrusionHow-toExtruder Steps3d Printer Calibrate ExtruderTo do this, simply open up a G-code terminal software on your computer, connect your computer to your printer’s motherboard (via USB), and send the “M92” command.Schlagwörter:How-toPrintersCalibrationCalibrate Extruder PronterfaceSchlagwörter:Extrusion3D Printing3d Printer Extruder CalibrationPrinters

Ultimate Guide to Perfect Calibration!

Some popular 3D printers allow direct E-steps calibration. See the installation document for information on setting up Klipper and choosing an initial config file.Loosen the tension spring so the filament doesn’t move through on its own and there’s no resistance feeding the filament. Go through the normal initialization .How to Calibrate & Dial in New Filament on Your 3D Printer

Extruder Calibration Guide (with calculator)

Now send the G1 E100 F100 to your printer; it slowly runs what the machine interprets as 100 mm extruded filament. In PrusaSlicer, navigate to Filament Settings and look for Extrusion Multiplier. This guide will help you better understand .I walk you through how to calibrate the extruder on a Creality Ender 5. Insert Filament into Extruder.3dprintbeginner.If you’re using Cura, you’ll want to know how to calibrate your extruder with it.

When performing the Flow Rate Calibration, you .1) Heat the nozzle to 180 ºC and remove any loaded filament. Using the values gotten from the calibration print, you’ll then calculate and set a new optimal value.

- How Do I Keep My Nvidia Gpu Drivers Up To Date?

- How Apple Cider Vinegar Burns Fat

- How Do I Contact Wizard101 Customer Support?

- How Do I Get A Creator Award? : How to get a Youtube creator award

- How Do I Access My Devices From A Google Account?

- How Do I Change A Setting On A Site?

- How Do I Find My Old Twitter Username?

- How Do I Calculate My Bradford Factor?

- How Do I Access A Steam Workshop In Civilization V?

- How Do Dopamine Neurons Work | How to Repair Dopamine Receptors Naturally

- How Do I Contact My Local Dpd Depot?

- How Do I Find A Blocked Person On Instagram?