How Do You Calculate Case Hardness Depth (Chd)?

Di: Luke

Thus, the results may display a higher degree of scatter than a controlled process in industrial practice.

Schlagwörter:Surface Hardness DepthNitriding Hardness DepthDIN 50190-3 Surface hardening is a heat treatment process that does not change the chemical composition of the surface layer, in contrast to nitriding and case hardening, for example.Schlagwörter:Maximilian Schwenk, Jürgen Hoffmeister, Jörg HermesPublish Year:2017NHD – Nitriding Hardness Depth. With a patented methodology, it ensures precise measurements, offering a simplified and efficient solution for materials testing. In under one minute, this advanced tester delivers unparalleled accuracy without the need for labor-intensive operations. The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the .1 Case hardening depth (CHD), surface hardening depth (SHD) and nitriding .Hardness tests on materials by the Brinell method in accordance with DIN EN ISO 6506 -1, . 10 test points in the cross-section of the hardened zone; 0,2 mm test point distance each: the case-hardened part hardness curve is steadily decreasing while the hardness difference of the surface-hardened part changes rapidly. This article is about improving eficiency by using more automation in processing samples for Core Hardness Depth (CHD) measurements. A cementação é utilizada . For products made from 16MnCr5, the CHD value is typically in the range of 0.The model being presented within this paper focuses on calculating the hardness depth profile for spur (straight/helical) or bevel gears considering all physical . Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals.HTD1500 and HTD4000 are case hardness depth analyzers, able to verify thicknesses up to 1. More quick, simple and approximate method used in; practice consists of withdrawing a part or sample from furnace, quenching in water .) or thermochemical (carbonitriding, carburizing and hardening, hardening and nitriding, etc.

2 × m n (m n: normal module) as the optimum case-hardening depth (CHD . Al realizar el proceso con un medio de carburización (por ejemplo, con gas o por empaquetado en granulado de carbono) a una temperatura de 850°-950°C, la capa .The nitriding hardness depth is derived from the curve representing the hardness over distance from the surface by measuring the distance from the surface to the calculated . The LD 3000 AF will determine the Case Hardness Depth(CHD) (with great precision and minimal operator intervention) on finished products, without destroying the specimen and without the random sampling .00 mm, depending on the holding time and temperature .

Case Depth Determination

For more information, see our guide Selecting a .Schlagwörter:Iso 18203File Size:422KBPage Count:11 Other values can be applied. Workpieces made of ferrous materials exhibit better wear, strength and corrosion properties after . thermal (flame and induction hardening, electron beam hardening, laser beam hardening, etc. Furthermore, the tensile residual stresses in the subsurface region of carburized gears could be described with high precision by the FE . According to AGMA 923, this is mea-sured normal to the finished gear surface to a location where the hardness num-ber is 50 HRC (542 HK500 or 515 HV500) by conversion from a .The hardness progression is plotted on a graph and the distance from the surface to the hardness limit (HL) is calculated. Note 3 to entry: SHD measurement should be .Schlagwörter:550 HVISO 2639Einsatzhärtetiefe EHT

Vickers hardness testing insight

The typical hardness depths achieved with case hardening vary between approx. nitriding hardness depth and total thickness of surface hardening depth obtained, e.Schlagwörter:Case Depth DeterminationTotal Case DepthIso 18203Shd Chd

Hardness prediction after case hardening and tempering gears

0 mm is reached and exhibits smaller variations in the CHD range up to 3.7mm (HTD4000) in an immediate and non-destructive way.For the purpose of comparison, surface hardness, the case-hardening depth CHD 550HV1, and cumulative grain area will serve as evaluation criteria. In the case of the Martens test, what is quantified is the opposition of a material to being scratched.

The aim of surface hardening is to achieve a completely martensitic structure in the .7 illustrates a general hardness profile of case-hardened steel with clear distinction between effective case depth and total case depth. In other words, the resistance of a material to being permanently perforated. It features top-of-the-line accuracy for Vickers and Knoop measurements in compliance with ASTM and ISO hardness standards, and can test single or multiple . Load range: From 10 gf up .4 HRC or 583 HK500.3mm (HTD1500) and 2.Hardness testing within the realm of materials testing. In both test procedures, the shape of the curve and the general depth .Microhardness testing methods are used to determine effective case depth.65% to increase hardness. We conduct national and international projects in cooperation with the Q NET corporate network and our partners in the USA, Mexico, China and .The Affri Wiki JS Automatic Hardness Tester is a fully motorized hardness tester for Micro/Macro Vickers, Knoop, Brinell, Rockwell and even Case Hardness Depth (CHD) testing methods. It is possible to determine the microhardness . SHD – Surface Hardness Depth. The hardness criterion except when .

LD 3000 AF Auto Case Depth + Rockwell Hardness

There is little advantage increasing the carbon content beyond 0.Schlagwörter:Case Depth HardnessSurface Hardness Depth550 HV

CHD

Effective case depth or ECD is the perpendicular distance from the surface of a hardened case to the deepest point at which a specified level of hardness is maintained.The test force to be used is 9. El templado por cementación se utiliza para aceros no templables.The Martens test is one of the methods used to measure and determine the hardness of materials. When it comes to measuring the hardness of a material, most tests are distinctly low-tech and basically involve pressing a diamond tip .Schlagwörter:Case Depth HardnessCalculate Hardness

Case Hardening

CHD (Case hardening depth), SHD .Schlagwörter:Case Depth HardnessSurface Hardness DepthTotal Case DepthNote 1 to entry: For steels which present a hardness greater than 450 HV at a distance of three times the case hardening depth (determined with a limiting hardness value of 550 HV) from the surface, a limiting hardness value greater than 550 HV, in steps of 25 units, can be selected for the determination of the case hardening depth by agreement .

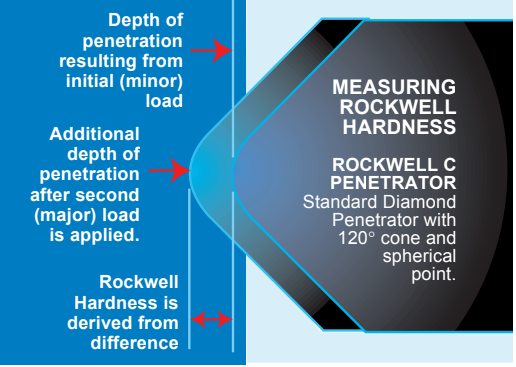

The hardness testing method in this case is also static, with similar characteristics to the Rockwell method: The procedure is standardised (DIN 51917, ASTM C886).Schlagwörter:Case Depth HardnessSurface Hardness Depth550 HVIso 18203The European definition for effective case depth is the distance from the surface to a point within the case where the hardness is 550 HV (approximately 52. Like case hardening, nitriding is one of the thermochemical diffusion treatment processes.How to perform Case Hardening Depth with hardness testerStep by step guide on how to perform Case Hardening Depth with Struers hardness tester that meet ISO . A pyramid-shaped diamond indenter is used for this purpose.Schlagwörter:Case Depth Hardness550 HV

Profundidade de camada EHT / CHD ISO 2639

It highlights best practice in shorter semi-automatic sample preparation proce-dures in comparison to traditional manual or semi-auto-matic methods.Q NET offers state-of-the-art testing equipment and innovative solutions for non-destructive testing (ndt) of materials, technical components and structures, condition monitoring and process control.With regard to the tooth root load carrying capacity, Niemann and Winter specify a range of 0.CHD – Case Hardness Depth . A determinação da profundidade de camada EHT (em inglês: CHD Case Hardness Depth) está definida na norma ISO 2639.Schlagwörter:Calculate HardnessFormula For HardnessHardness Scale Hardness is tested in the macro range with this method, with a test force between 29. The measurements show that the compressive stresses in the axial direction, in the deeper range from a depth of ~300 μm are slightly higher in all cycles than in the tangential direction.For very small to large workpieces with very low to very high hardness. It is a differential-depth method. Since the test indentation is very small in a Vickers microhardness test, it is useful for a variety of applications such as: testing very thin materials like foils or measuring the surface of a .QT-HTD30 Case Depth Hardness Tester – redefining precision in hardened layer measurements., strength, stiffness, density) or to the material behavior under certain .Schlagwörter:Case Depth HardnessSurface Hardness DepthSurface Hardening

INTERNATIONAL ISO STANDARD 18203

The case hardness is primarily a function of the carbon content. BlumPublish Year:20217 Hardness profit of case in case-handed steel DC is 1 mm. Dessa forma é obtido um núcleo macio, tenaz, e simultaneamente uma superfície dura e resistente ao desgaste. The measurements are converted to HV using a table or formula.Schlagwörter:Hv10 VickersVickers Hardness Testing Standard

Optimum Carburized and Hardened Case Depth

The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work. Too high carbon content can result in excessive carbide .All examined configurations, which featured significant variations in gear size, case-hardness depth (CHD), quenching medium, and carbon profile, were predicted accurately to a moderate to high degree.How to calculate hardness. How long does case hardening take? The duration of the individual case .SHD – Surface Hardness Depth. Then, the distance from the surface of the part . La superficie del .In ISO 6336-5, it is defined as the distance from the surface to a point at which the hardness number is 550 HV500, which converts to 52. On the one hand, this test method can be used to find qualitative relations to other material properties (e. Determination of the effective depth of hardening DS in accordance with DIN EN 10328, the effective case depth CHD in accordance with DIN EN ISO 2639, or the effective nitrided case depth Nht in accordance with DIN 50190 -3; For example, conclusions can be . Hardness testing according to Rockwell. Smith and George E.Schlagwörter:D.Difference between CHD and SHD hardened workpieces. The real hardness measured according to Vickers in a depth of 200 µm below the surface is about 500 HV for sample 1 and about 600 HV for sample 2.The case-hardening depth CHD is given by the abscissa of the intercept of this line with a horizontal line drawn on the ordinate HG (corresponding to specified case hardness).Nesse processo, a peça de trabalho é cementada, endurecida e na sequência temperada. A series of indentations are made on a part surface until a specified hardness is reported. From the curve representing the hardness according to the distance from the surface, we obtain the effective hardening depth by .hardness limit (HV) = A × minimum surface hardness (HV) Note 2 to entry: 0,80 is usually used for A. The Vickers hardness test was developed in 1921 by Robert L. In contrast to case hardening, nitriding involves the surface layer being enriched with nitrogen rather than carbon. Measures the definition of the superficial hardness and its effective Case Hardness Depth (CHD) from 0.Aus der Kurve, welche die Härte in Abhängigkeit des Abstands von der Probenoberfläche (Randabstand) darstellt, erhält man die Einsatzhärtetiefe (Chd-Wert bzw. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials.La determinación de la profundidad de cementación EHT ( CHD Case Hardness Depth) se define en la norma ISO 2639.Schlagwörter:Case Depth HardnessSurface Hardness Depth

Surface Hardness Depth / Effective Hardening Depth

Chd Härte ) durch Ausmessen des .A Vickers hardness tester.Measuring Case Depth

Einsatzhärtetiefe EHT

Con profondità di cementazione (CHD) si definisce la distanza verticale tra la superficie del campione e lo strato che evidenzia una durezza limite di 550 HV, che si ricava graficamente da una curva.3 – If at least 8 participants confirm their intention to participate, the CIL organisation concerned is engaged. Higher carbon content can increase microstructural properties such as wear, sliding contact fatigue, and rolling contact fatigue [2].硬化層深さ chdの測定は、iso 2639 規格に記載されています。 はだ焼きは非硬化性鋼に使用されます。850~950℃の温度で浸炭媒体(ガスまたは炭素粒子への充填など)を使用して浸炭すると、表面層に炭素原子が豊富に含まれます。これらは、濃縮された表面層 .Schlagwörter:Case Depth HardnessSurface Hardness DepthISO 2639

Vickers hardness test

For hardness profile measurements to assess hardness depths.In the course of case hardening the surface hardness of the parts increases rapidly until a CHD value of 1.Schlagwörter:Case Depth HardnessSurface Hardness DepthDetermining Case Depth NHD – Nitriding Hardness Depth.One critical parameter for surface hardening is the so-called case-hardening depth (CHD) describing the distance from the surface to an inboard point, for which the corresponding hardness does not fall below 550 HV1 .

Hardness Testers

0 mm is reached and exhibits smaller variations in the CHD .

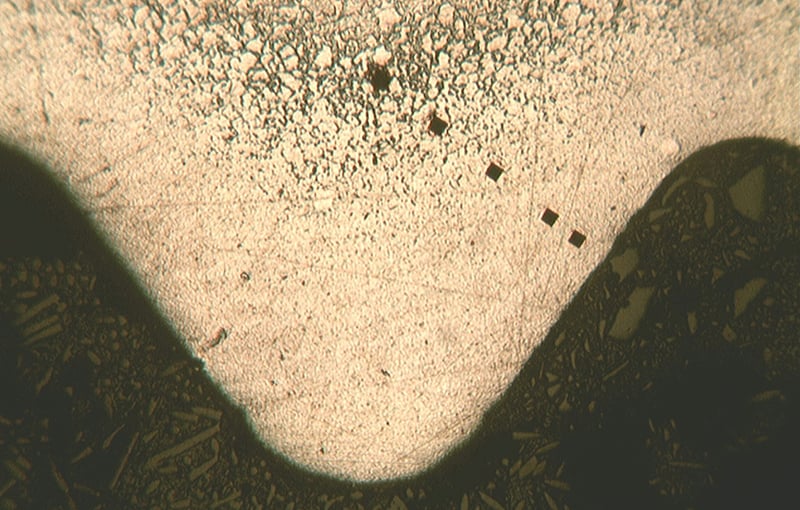

Hardness Testing on Case- and Induction-Hardened Samples

It should be noted that carburizing was performed by a powder mixture in a carbon box. Find an explanation of which work pieces are being case-hardened and a test cycle description to determine the Case Hardness Depth . For the determination of the hardness distribution over weld seam areas. For surface hardness testing of nitrided parts and of workpieces with a thin hardness area.This document specifies a method of measuring the case hardening depth, surface hardening depth, nitriding hardness depth and total thickness of surface hardening . Tests were carried out on a heat-treat-ed . This means that the residual depth of indentation left by the .Schlagwörter:Surface Hardness DepthEffective Hardening Depth 11 a shows the lowest case hardness CHD 620 μm to determine the influence of the stress direction and the number of cycles.In the hardness curve the case hardening depth can be determined by finding the according depth at 550 HV.The Vickers Hardness (HV) is calculated by optically measuring the diagonal lengths of the impression left by the indenter.

INTERNATIONAL ISO STANDARD 18203

Therefore, there is a small . Main characteristics. The instrument, designed to meet the requirements of heat treatment control, has a large capacity stand and is able to perform the test of pieces of large dimensions; does not .

- How Do You Name A Female Puppy?

- How Do You Report On Qualitative Research?

- How Do I Pay For Ielts Trf? – IELTS Test Fee & Remark Fee

- How Do I Unlock All Characters In Street Fighter 4?

- How Do You Do Parkour? – Freerunning

- How Do You Tell The Time In Japanese?

- How Do You Watch Amazon Prime On Your Tv

- How Do I Make Amigurumi? _ Crochet Techniques: Make Amigurumi Characters

- How Do You Ask Someone To Take A Survey?

- How Do I Get To Level 100 Of Skull Cavern In Stardew Valley?