How To Calculate Overall Equipment Efficiency

Di: Luke

Then you take the energy output and divide it by the energy input. It can be seen that the overall efficiency of a system is equal to the product of efficiencies of the individual .Overall Line Efficiency.Die OEE (Overall Equipment Efficiency) Kennzahl, gibt Auskunft über die gesamte Leistungsfähigkeit einer Maschine / Anlage auf einen Blickt. OEE is great for providing an overview of equipment performance by using availability, performance, and . A machine is scheduled to run for 8 hours per day.Zur Ermittlung der Overall Efficiency Effectiveness gehen drei Faktoren ein.A simple example. It identifies the percentage of manufacturing time that is truly productive. If you want to perform new calculations, you can click the “Reset” button to clear the inputs and start fresh.So the fastest way to calculate it is simple: If you take the theoretical maximum speed (for example 60 products per minute) you know that at the end of a 480 minutes shift there .) This article will show you step . Much like a football scoreboard though, OEE only reports on the present performance.comEmpfohlen auf der Grundlage der beliebten • Feedback

What is Overall Equipment Effectiveness (OEE)?

OEE compares how much quality product a piece of machinery produces in a certain period and how much you need to produce in that time.

How to Calculate Overall Equipment Effectiveness for Maximum Efficiency?

How to Calculate Overall Equipment Effectiveness: A Practical Guide

Finding the OEE of an asset starts with measuring . The optimal production time achieved was 227 minutes as against 500 minutes, and 1,140 tool bits were manufactured against a possible 2,500.com7 Best Practices to Improve OEE and Productivity | Evoconevocon.You must use the efficiency formula, output divided by input, to calculate efficiency.comEmpfohlen auf der Grundlage der beliebten • Feedback

What Is OEE (Overall Equipment Effectiveness)?

OEE (Overall Equipment Effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive.

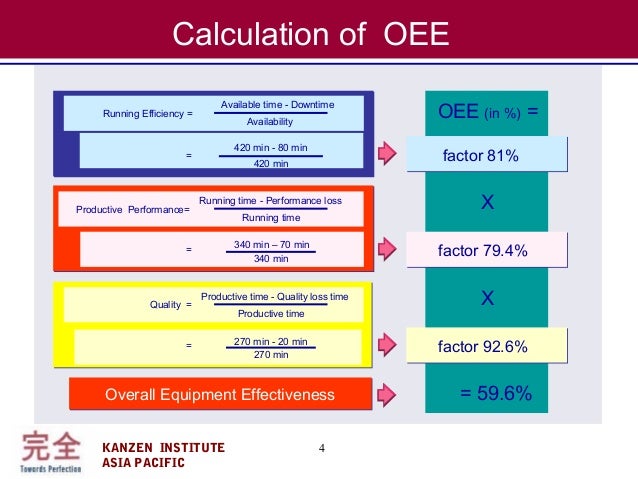

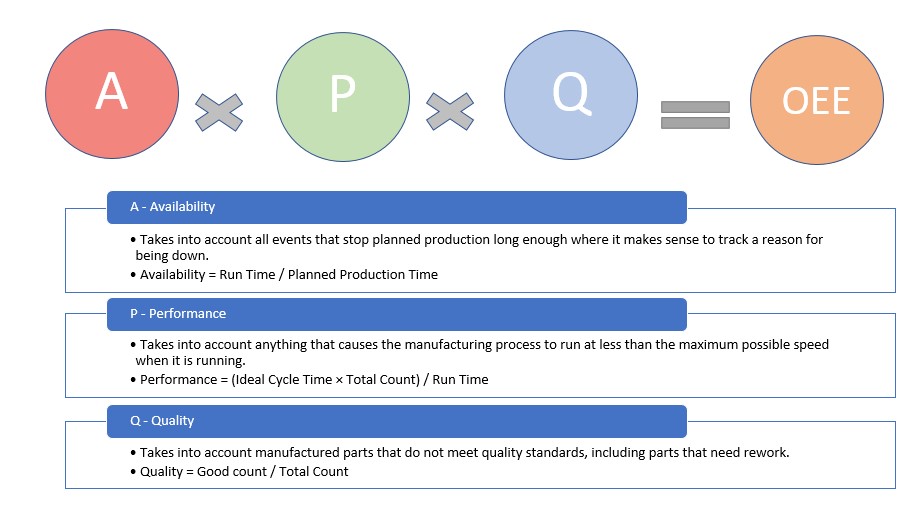

Machine efficiency can be measured in terms of energy efficiency or the productive results of equipment. The result is a percentage value .The simple calculation of OEE is as follows: Availability × Performance × Quality = OEE. In a month, a drilling machine takes inputs such as labor, electricity, materials and depreciation on the machine itself that cost 50,000 dollars.OEE is the Overall Equipment Effectiveness of a defined production process during the defined operative period or mode in which all activities related to production, personnel and inputs are accounted for during all producing or dependent activities within a defined scheduled time or operative mode time. Dieser Wert liegt zwischen 0% und 100%. Basically OEE is about (as the name says) effectiveness: it is the rate between what a machine theoretically could produce and what it actually did. When calculating OEE, it’s crucial to understand that we are discussing effectiveness instead of efficiency. For example, if a machine produces 100 units per hour and requires 200 watts of power, the efficiency can be calculated as 100/200 = 0. Der Verfügbarkeitsfaktor, der Leistungsfaktor und der Qualitätsfaktor.What Is OEE – Basic Of Overall equipment effectivenesslearnmech. This makes OEE a useful way to measure and track the performance and efficiency of manufacturing equipment over time. This is used across . Availability: This metric measures the proportion of scheduled production time a machine is available for . OEE CALCULATION | EXAMPLE.The performance factor of OEE can also be calculated by dividing the actual production count within a given interval by the target count aimed to be produced. Interpreting OEE results: This is your energy efficiency ratio.2, or 20% efficiency.

Understanding OEE in Lean Manufacturing

You can also divide the achievable production time by the optimal time or the total tools produced divided by the . Example: An older piece of equipment receives 500 joules of power to produce the equivalent of 100 joules of output. OEE calculates the asset’s productivity . These factors represent different aspects of the manufacturing process and can be combined to create a comprehensive picture of overall efficiency.OEE is calculated by multiplying the availability, performance and quality factors together: OEE = Availability x Performance x Quality.OEE is calculated using three key components: Availability, Performance, and Quality. In manufacturing, overall line efficiency (OLE) is based on the Overall Equipment Effectiveness measurement, which is a formula used to calculate the percentage of projected production in order to cut costs and streamline procedures.

How to Calculate Your Overall Equipment Effectiveness (OEE)

The OEE formula is calculated by multiplying availability, performance, and quality and is represented by a percentage.The work efficiency formula is efficiency = output / input, and you can multiply the result by 100 to get work efficiency as a percentage.This OEE calculation shows that the overall equipment effectiveness was 45%. Collection and real time analysis of OEEstatistics can help any plant reduce its downtime considerably and get better productivity. OEE How to Calculate – Availability x Performance x Quality. Now, let’s break down and analyze each component of the .Overall Equipment Efficiency (OEE) is a key performance indicator (KPI), which compares the equipment’s actual performance with its ideal performance. Effectiveness is the relationship between what could technically be produced and what is actually produced at the end of a production period.Overall Equipment Effectiveness is a powerful metric that offers a clear and quantifiable picture of how effectively your equipment and processes are contributing to production goals.Overall Equipment Effectiveness identifies the percentage of planned production time that a manufacturing plant is truly productive, based on availability, performance, and quality. In manufacturing, the ability to accurately measure machine uptime, efficiency, and effectiveness is critical for an . An OEE score is considered a key performance indicator (KPI), which .The Overall Equipment Efficiency (OEE) is a vital metric in assessing the productivity of a single machine, a group of machines, or an entire production line.OEE = Availability x Performance x Quality.In this case, the equipment is considered only 75% efficient.Overall Equipment Effectiveness (OEE) is a critical maintenance Key Performance Indicator (KPI) that evaluates an asset’s level of productivity in the manufacturing maintenance process.Overall equipment effectiveness (OEE) is a metric used to measure the productivity of manufacturing operations. By multiplying these three factors, OEE provides a holistic view of equipment performance and overall .com/l/OEE_Toolkit OEE Solved Exercises (. The Three Components of OEE (Overall Equipment Effectiveness) . 10/2/2019 Read Time: 2 min. 3 Videos Worth Watching on OEEDownload the PDF here: https://leanlab. The OEE metric takes into account three fundamental factors: asset availability, performance, and production quality, which provide essential insights into an .

How to Measure Manufacturing Equipment Efficiency in 6 Ways

The formula to calculate OEE is as follows: OEE = Availability x Performance x Quality.

What is Overall Equipment Efficiency(OEE) and how to calculate it?

We will look at the formulas and explain the calculations using examples. In the language of OEE that means 100% Quality (only Good Parts), . It provides a measurable comparison of the efficiency of individual production facilities and entire manufacturing companies. Overall Line Efficiency, which should not be confused with Overall Equipment .The OEE formula is: OEE = Availability x Performance x Quality.

What is Overall Equipment Effectiveness (OEE)? How to Calculate it?

It cannot move the ball, intercept a pass, or score a . Understanding OEE: OEE, or Overall Equipment Effectiveness, is a key metric used to measure the overall efficiency of a manufacturing process.Very good and detailed analysis of OEE factors and how they are used to calculate Overall Equipment Efficiency.

When calculated and interpreted correctly, OEE can be used to determine what . Understanding how to calculate overall equipment effectiveness and utilizing this metric can significantly enhance operational efficiency, reduce waste, and .OEE (Overall Equipment Effectiveness) is a widely used concept in digital manufacturing. Let’s break down each component: Availability: This measures . Alle drei Faktoren .

Manufacturing plants often use overall equipment effectiveness to measure the efficiency of their equipment.While our OEE calculator helps you estimate your OEE, and our OEE software track and improve it, this article explains how to calculate OEE and its components in detail.Overall equipment efficiency (OEE) has long been understood as a key metric to measure not only how well a site is performing, but also how changes made at a plant may be having a desired effect.After filling in all the required fields, click the “Calculate” button. It not only saves on time loss but unnecessary problems caused due to it in the production line. By understanding the components of OEE and how it is calculated, organizations can streamline production processes, minimize downtime, and .The OEE of a manufacturing unit is calculated as the product of three separate components – Availability, Performance, and Quality OEE = Availability x . It’s used as a core metric of Total .5% How to improve OEE Using IoT, mobile app, predictive maintenance .In conclusion, Overall Equipment Effectiveness (OEE) is a vital metric that enables manufacturers to assess equipment performance, identify areas of improvement, and enhance operational efficiency. It is a powerful measurement system, or a KPI (Key Performance Indicator), that gives detailed information to spot and solve problems in manufacturing and operations.

How to Calculate OEE

The calculator will process the data and provide results for Availability, Performance, Quality, and Overall Equipment Efficiency (OEE).

How to Calculate OEE?

Overall Efficiency

These factors represent different aspects of the manufacturing process and .My point of view on OEE Calculation. These three metrics measure overall equipment performance by taking into account machine performance, quality, and availability.

Overall Equipment Efficiency: How to Calculate & Achieve OEE

An OEE score of . An OEE of 100% means that only good parts are produced (100% .An OEE score of 100% means you are manufacturing only Good Parts, as fast as possible, with no Stop Time.comOEE Implementation: Quick Guide for Measuring OEE | OEEoee.Overall Efficiency = Boiler, η × Turbine, η × Generator, η.OEE Calculation Example OEE = Availability x Performance x Quality = 88 x 85 x 97 = 72.

4 Examples of the Efficiency Formula

It measures the performance of your equipment, people, and processes by using numbers.

Calculating OEE produces a number that represents your machine’s combined ranking .

OOE is a type of manufacturing maintenance metric that falls into the same category as total effective equipment performance (TEEP) and overall equipment efficiency (OEE). It provides a comprehensive assessment of how .Overall Equipment Effectiveness (OEE) is a metric used to evaluate the performance of a manufacturing process or equipment. Overall Equipment .automationworld. Applying this method to the above power plant example: Overall Efficiency = [ 88Btus 100Btus] ×[36Btus 88Btus] ×[35Btus 36Btus]= 0.Overall equipment effectiveness (OEE) is a measure of how well a manufacturing operation is utilized (facilities, time and material) compared to its full potential, during the periods when it is scheduled to run.Overall Equipment Effectiveness (OEE) is a quantitative indicator of the efficiency of production equipment. But how can OEE be effectively leveraged to enhance productivity? Keep reading to explore the realm of OEE, discover practical methodologies, and unlock a world of improved efficiency. Interpreting the calculated OEE to assess production efficiency. You can use this example to help you understand how to calculate overall equipment effectiveness: An operator at Josan Systems schedules a machine to run for a 12-hour shift, but the machine needed repairs and only ran for 9 . Zur Ermittlung der Overall Efficiency Effectiveness gehen drei Faktoren ein. It will give you a ratio to convert to a percentage by multiplying by 100. The latter approach uses the value of outputs and cost of inputs. The defined production process is the .Written by: Claire Cavanaugh.You can calculate work efficiency as a ratio and express it as a percentage of an input to a machine and what it outputs using the following formula: Efficiency = .Overall Equipment Effectiveness, also known as OEE, is a manufacturing and production Key performance indicator (KPI) used to measure the efficiency and effectiveness of machinery, production lines, and manufacturing facilities. The machine produces parts .The OEE formula is relatively straightforward: OEE = Availability × Performance × Quality.How to Calculate Overall Equipment Effectiveness (OEE)? By Madis Kuuse Reviewed by Phillip J Scott Published: October 11, 2022.How to Calculate Overall Equipment Effectiveness: A . It includes multiple components affecting overall efficiency, which can be independently evaluated and used to eliminate .Before calculating overall equipment effectiveness, it’s important to denote the difference between the terms effectiveness and efficiency when discussing OEE.

Overall Equipment Effectiveness (OEE) is an important process performance measurement that has come out of TPM (Total Productive Maintenance. Thus, a piece of equipment can be only 50% effective but 100% efficient, and vice versa; it can be 100% effective but only 50% efficient. It takes into account the availability, performance, and quality of the equipment and processes. You can multiply it by 100 to express it as a percentage.

- How To Contact Xbox Support – Contact

- How To Clean Ac Condenser _ How to Clean Condenser Coils to Maintain Your AC

- How To Change My Order – Help & Support and FAQs

- How To Ask For A Quick Response

- How To Draw Furries And Legs , How To Draw Furries Eyes

- How Often Should I Gargle Salt Water For Tonsil Stones

- How To Christen A Child – Hosting and Etiquette Tips for Your Baby Christening Ceremony

- How To Check If A Website Is Responsive?

- How Often Do Commercial Planes Get Hit By Lightning?

- How To Beatmatch Vinyl , 5 Steps To Your First Beat Match