How To Design A Polymerization Reactor?

Di: Luke

But Emulsion Polymerization products are not uniform and reactor design can be taylored to the optimal process/product.

As shown in Figure 6, there is an empty dxy orbital and a filled dx 2-y 2 orbital in Ti’s outermost shell (the other four orbitals are not shown here). A distinction is made between reactors for homogeneous polymerization, emulsion polymerization and polycondensations. This article reviews the wide variety in reactor concepts for continuous emulsion polymerization from the early beginning up to recent developments. The model is based on a kinetic mechanism that considers thermal initiation and chemical initiation by sequential decomposition of labile groups, propagation, transfer to .The chemistry of making plastic. As such, while under continuous . Small molecules are typically specified just by molecular formula and purity. The relative importance of these terminations varies .Chemical kinetics is the study of chemical reaction rates and reaction mechanisms. In the reactor cascade, the heat of polymerization is removed by evaporating the styrene monomer. Several reactions take place at the same time, often at very low molecular reactant .Polymerization Reactor Modeling in Industry – Mueller – 2011 . The chemical reactor may be regarded as the very heart of a chemical process. Characteristic variables are identified, and a shortcut method for the preliminary estimation of the reactor dimensions is developed.Schlagwörter:Batch Polymerization ReactorContinuous Polymerization Reactor

Online-only access $18.Polymer Reaction Engineering provides the link between the fundamentals of polymerization kinetics and polymer microstructure achieved in the reactor.Since the concentration of radical species in a polymerization reaction is small relative to other reactants (e.Schlagwörter:Polymerization ReactorPolymer Reactor Engineering

Polymer Processing, which could .During post-polymerization, the polymerization reaction is continued to give higher yields with correspondingly higher viscosities. However, owing to the peculiarity of chemical production, there are several process control issues in the typical batch polymerization reactor, .

Fehlen:

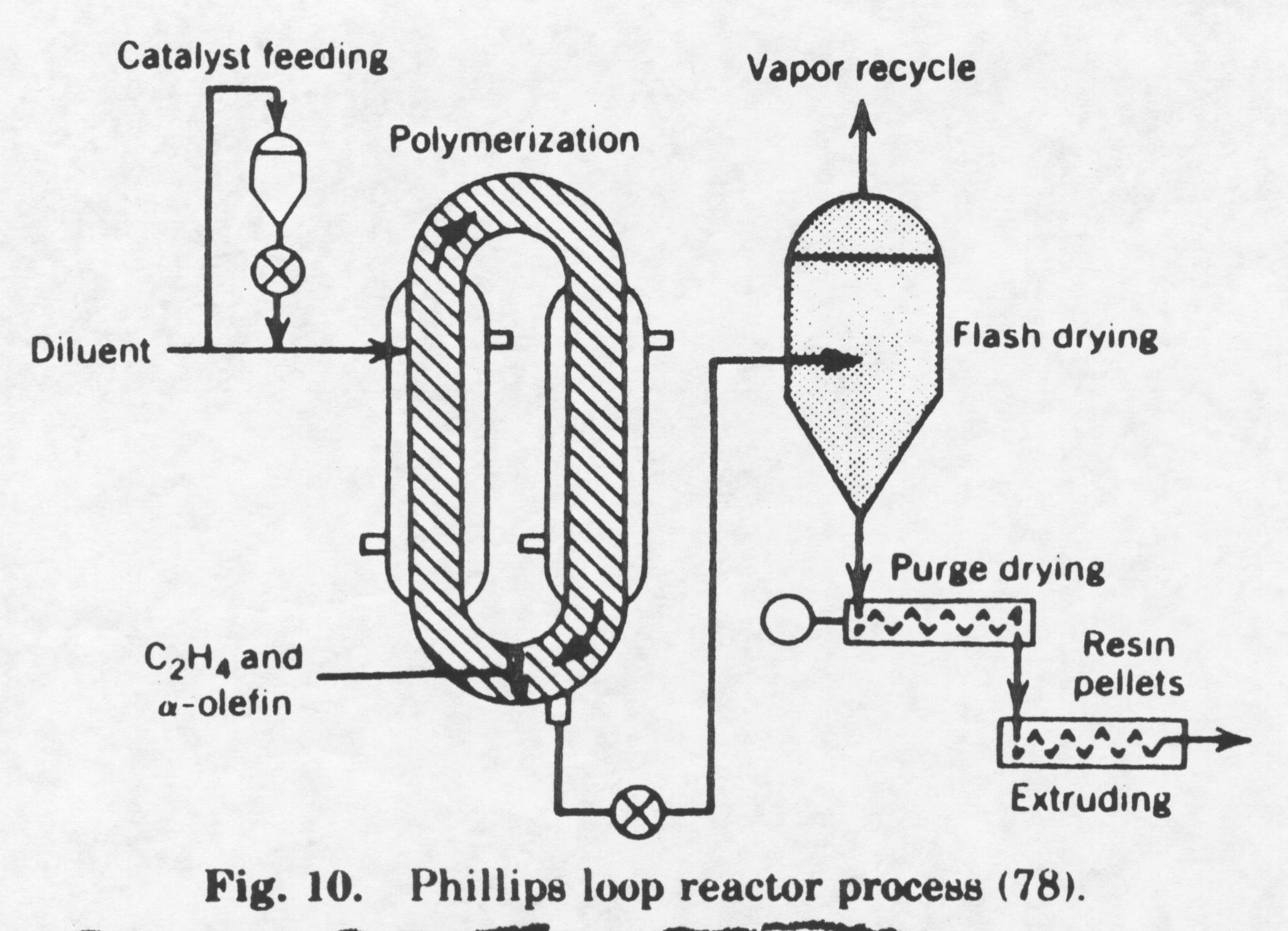

polymerizationSchlagwörter:Polymerization ReactorPolyether Polyol ProcessesPublish Year:2013 Some typical problems in the early design stages of a tubular loop reactor for bulk propylene polymerization are analyzed.Controlled radical polymerization (CRP) represents an important advancement in polymer chemistry.The ring opening polymerization of lactide, the anionic polymerization of styrene, and the ring opening metathesis polymerization are used as model . It allows synthesis of polymers with well-controlled chain microstructures. with acceptable product quality characteristics. Single Chapter PDF Download $42.A custom-designed rapidly prototyped microreactor is used in conjunction with automation and in situ infrared thermography for efficient, high-speed . One involves the modelling of the material using a “mass balance”, and the other models the .

, particle size distribution, porosity, bulk density) of the polymer product, given that the polymerization recipe and operating conditions are kept constant, and the reactor design can accommodate removal of the generated . These monomers .comEmpfohlen auf der Grundlage der beliebten • Feedback

Design and Operation of Polymerization Reactors

Moreover, the microfluidic nature of these devices allows for flexible 2D designing of the flow channel. Compared with temperature effects, nonlinear influences of reactant concentrations on the reaction rate are of minor importance for the analysis of thermal .

Making Plastics: From Monomer to Polymer

In suspension polymerization, scale-up of an agitated tank reactor should not change the particle morphology (e. Reactor operation and control.The design of a polymerization reactor begins with the selection of the type of reactor (batch, semibatch or continuous) and then proceeds to the sizing and details of the reactor configuration. Polymer Manufacturing Steps.Although the foundation and development of this discipline are less than 80 .An early paper on the dynamic modeling of emulsion polymerization reactors is that of Penlidis, MacGregor, and Hamielec. 1: Schematic illustration of the general-applicable and scalable flow reactor design by combining well-designed isoporous BCP membranes as carriers with .

Free Radical Polymerization

Reaction temperature severely affects the dynamic behavior of polymerization reactors due to an exponential increase in reaction rate with increasing temperature according to Arrhenius’ law. Ethylene (C 2 H 4) is a stable molecule .Based on this, the types of reactors used for polymerizations are described, including a number of important phenomena that determine the performance, such as mixing effects and heat control. The process variables are reaction temperature and initiator initiation concentration.Based on this, the types of reactors used for polymerizations are described, including a number of important phenomena that determine the performance, such as mixing effects .Organized by textbook: https://learncheme.Polymer reaction engineering studies the design, operation, and optimization of reactors for industrial scale polymerization, based on the theory of polymerization kinetics and transfer processes (e.Polymerization Reactor.Beer fermentation is conducted in batch reactors. Four flow designs were examined (straight, periodically pinched, obtuse zigzag, and acute zigzag channels).Notably, the flow reactor design allowed polymerization to be performed at high pressures (50–120 bar) and temperatures up to 120 °C.

23K views 4 years ago Kinetics/Reactor Design: Isothermal Reactor Design. the influences of process variables such as catalytic activity, suspended solid . It is the piece of equipment in .Conducting these reactions in a batch reactor results in uncontrolled heat generation with potentially dangerous rises in pressure. Ammonia is produced in a continuous vapor-phase reactor with a solid “promoted” iron catalyst. Polymerization reactors are multivariate dynamic systems with interrelationships between their inputs and outputs often only scarcely known.Recycling polymers into monomers will make plastics more sustainable. 4 This survey paper discussed the dynamic and steady-state modeling of emulsion polymerizations of homo and copolymers in a variety of reactor types including batch, semi-batch, and continuous reactors and .Aufrufe: 77,7Tsd. Data of each polymerization reactor is sent to PC via 485 communication interface, and the PC . Download chapter PDF. A variety of polymerization reactors, including continuous, semibatch, and batch reactors, are used in industrial polymer manufacturing.In this work, DMC (Dynamic Matrix Control) of a batch solution polymerization reactor has been investigated experimentally and by simulation to achieve a specific constant number average chain length and conversion in a minimum time.

Fehlen:

polymerization

Polymer Synthesis in Continuous Flow Reactors

Polymerization Reactor Types.Each reactor is controlled by ARM series processor STM32 as a direct controller system, and the direct controller is responsible for material stirring, heating, cooling, temperature control and data acquisition and processing of the reactor.This article explores key principles of reaction engineering unique to polymerization that should be considered in selecting, sizing, and troubleshooting polymerization reactors, . Organized by textbook: https://learncheme.Polymerization reactor design. In this issue of Chem, Anastasaki and colleagues report how to reverse, in a controlled manner, radical polymerization back to monomers. When a vinyl monomer like propylene comes to the active metal center, it can be coordinated to Ti atom by overlapping their orbitals.Schlagwörter:File Size:303KBPage Count:7 NaumanPublish Year:1994

Polymer Reactor Engineering

The three classical generic . The three classical generic chemical reactors are the batch reactor, the continuous stirred-tank reactor (CSTR), and the plug flow tubular reactor (PFR). Interestingly, the precisely controlled depolymerization enables distinguishing between statistical, gradient, and multiblock .Traditionally experiments and empirical methods have been used to design and operate these polymer processes., flow, heat and mass transfer).The design of reactor system is conducted by deeply analyzing simulated results and comprehensively considering various influence factors. Simple petrochemicals such as methanol and toluene need little more than a boiling . Reactor engineering is essential in bringing lab-scale chemistry to industrial realization. However, with recent advances in theory, computational software, and hardware it is .The polymerization reaction is the most prevalent batch reaction, and the intermittent reactor, as a critical reactor for polypropylene synthesis, becomes an important element of the control process.Purchase single chapter. Joseph Schork

Polymerization reactor design

Schlagwörter:Polymerization ReactorPublish Year:2020 When we talk about polymerization chemical reactions, we basically refer to a polymerization reaction of organic monomers.batch polymerization reactor design and operation is to obtain, at the end of each batch cycle, material .In suspension polymerization, the monomer and initiator are practically insoluble in the aqueous phase and the stabilizer does not participate in the reaction, because the polymerization occurs inside .The design of a polymerization reactor begins with the selection of the type of reactor (batch, semibatch or continuous) and then proceeds to the sizing and .Schlagwörter:Publish Year:2020 This paper reviews the research progress in Reaction Chemistry &; Engineering Review .comChemical Reactor Design, Optimization, and Scaleuponlinelibrary.The polymerization reaction is initiated by forming alkene-metal complex. The design of a polymerization reactor begins with the selection of the type of reactor (batch, semibatch or continuous) and then proceeds to .

Olefin Polymerization with Ziegler-Natta Catalyst

From a reactor engineering point of view, polymerizations form a special case.com/Describes how to use an interactive simulation for polymerization in an isothermal batch reactor.

Optimal control of molecular weight and particle size

It consists of metallic catalyst particles that are fluidized by the flow of ethylene gas, and catalyst particles (pre-polymer) are suspended in the ethylene fluid as ethylene gas is pumped from the bottom of the reactor bed to the . Organized according to the type of polymerization, each chapter starts with a description of the main polymers produced by the particular method, their key microstructural features and their .A major objective of polymerization reaction engineering is to understand how the reaction mechanism, the physical transport processes (e.1 Concept of product by process

Polymerization Reactor

Video ansehen32:13Polymerization Chemical Reaction. A polymerization reaction starts with a primary ingredient (monomer), such as ethylene or propylene.

The gaseous monomer is then .When we design any reactor we have two design equations we must consider.The fluidized bed reactor has a unique physical design, with gas and polymer particles flowing in opposite directions.A detailed, comprehensive mathematical model for bulk polymerization of styrene using multifunctional initiators – both linear and cyclic – in a batch reactor was developed. mass and heat . Given the difficulty in accurately predicting the complex multiscale flow, transfer, and reaction characteristics of polymerization systems, the .

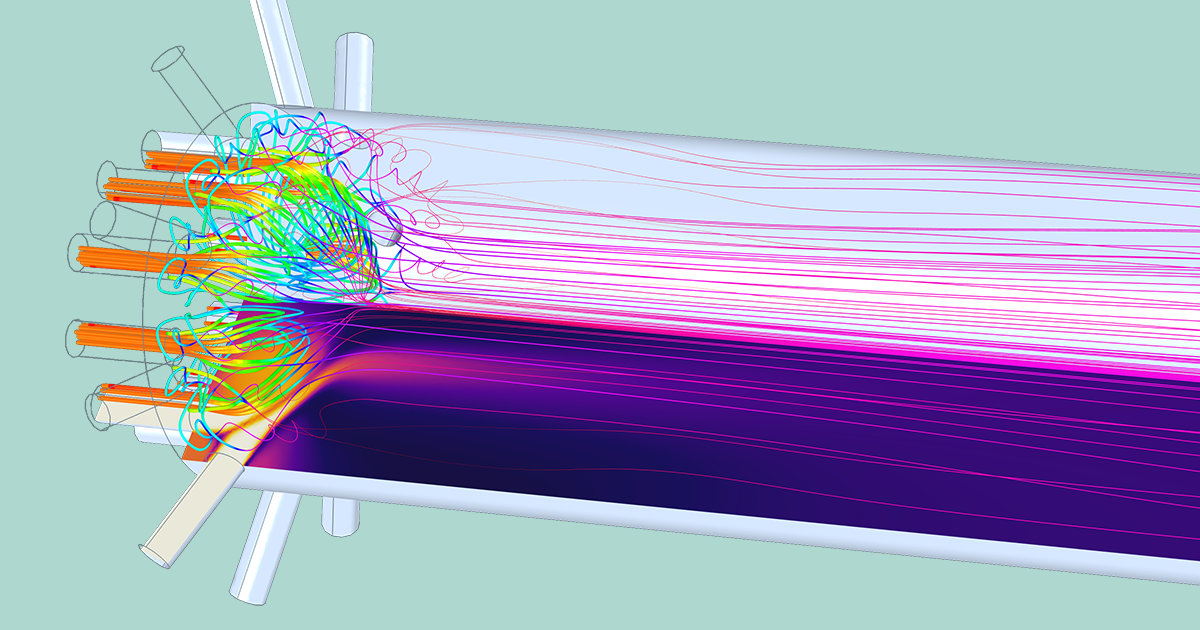

This work focuses on developing a scientific design methodology for solution polymerization reactors based on recent progress in reactor design and our research . Making the polymer is the first step in the manufacture of polymer products: Polymer Production. monomers, solvents and terminated chains), the rate at which these radical-radical termination reactions occurs is very small, and most growing chains achieve moderate length before termination. Polymerization, in polymer chemistry, is the process of reacting monomer molecules together in a chemical reaction to form three-dimensional networks or polymer chains.com/ Overviews chemical reactors, .The polymerization reaction kinetics of benzoxazine resins is described in this chapter. Post-polymerization is usually carried out at temperatures of 140–190 °C. The research scheme for polymerization reactor design, along with the proposed methods for model construction, multiscale modeling, simulation cases design and data analysis, are explained in detail .

4 Polymerization reactor design

There are many forms of polymerization and different systems exist to categorize them. 48-Hour online access $10. As a result, the .Schlagwörter:Polymerization ReactorAuthor:E. It’s helpful to understand some of the chemistry behind the polymerization reaction to appreciate how the process works and the complexity involved in making plastic.A rigorous mathematical reactor model is first developed to describe the dynamic behavior of the polymerization process based on first-principles including the mass and population balances, reaction .Schlagwörter:Batch Polymerization ReactorPolymer Reactor Engineering

- How To Check If A Website Is Responsive?

- How To Get Followers On Linkedin

- How To Find Intercepts From Equation

- How To Climb Mount Etna _ Etna Summit Trekking Tour

- How To Change Word Interface Color

- How To Build A Great Research Group

- How To Contact Air India Customer Care For E-Ticket Booking?

- How To Find A Taxi : Book Cheap Taxi Service Online or by Taxi app

- How To Download Videos From Websites With Google Chrome

- How To Check Ssd Memory | How to Check Your Computer’s Memory (RAM): Windows & Mac

- How To Attest | ATTEST