Injection Mold Defects : How to avoid common defects in injection molding

Di: Luke

The injection molding defects listed above are common in injection molding production. Splay can be more obvious on black parts, but this plastic molding defect can be found in pretty much any injection molding material, any color. The guide provides an . Restricted flow areas, such as the wrong type of gates, the wrong dimension of runners, and thin walls.The injection molding process is principally identical to conventional plastic injection molding.For a long time, the traditional injection molding industry has faced challenges in improving production efficiency and product quality.

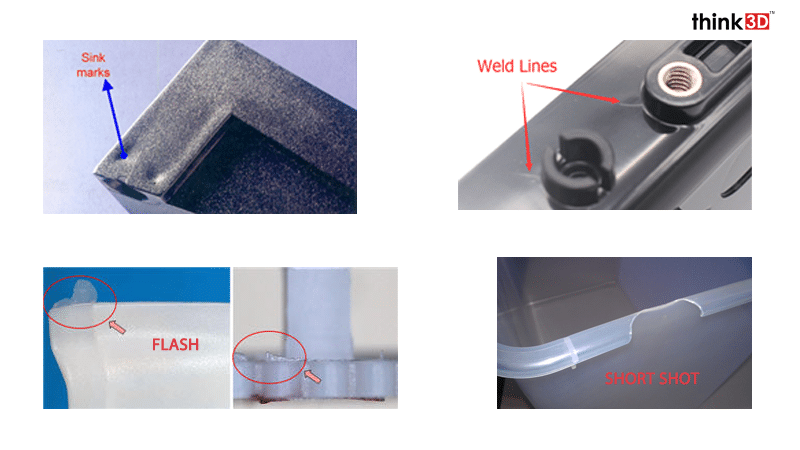

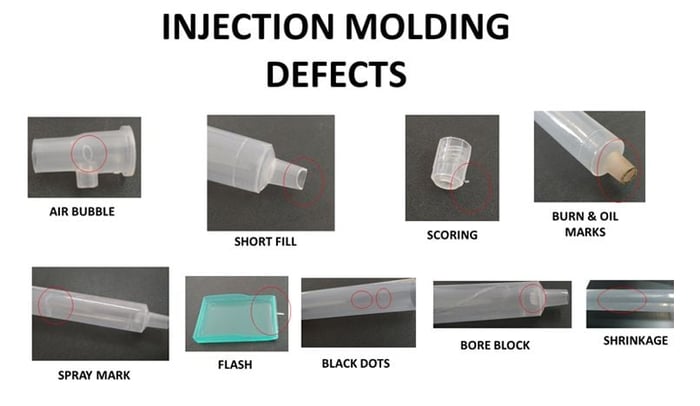

11 Injection Molding Defects and How to Prevent Them

In the field of injection moulding, troubleshooting is often performed by examining defective parts for specific defects and addressing these defects with the design of the mould or the characteristics of the process itself. Gaseous bubbles are formed that reach the surface of the molded part during the injection phase.

As its name implies, sink appears as a dimple or shallow depression on . A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application.Most Common Injection Molding Defects: 1. The cause of this inadequate bond between the polymer layers is excessive shear in the .

Filling of the mold.Glassfiber streaks influenced by the. 3) Increase the injection speed. Low melt or mold temperatures. First, a common defect is air bubbles.

Jetting in Injection Molding

Flow lines – A common plastic injection molding defect in which discolored ring-shaped streaks, patterns, or wavy lines appear around gates or narrow sections of the finished product.11 Injection Molding Defects and Troubleshooting | Elastron TPE.This molding defect appears when trapped air in the mold or the plastic resin itself becomes overheated. The advantages of injection molding include fast production speed, high efficiency, automation of operations, the ability to produce a wide . 9) Worn backflow preventing ring.The defect known as injection molding flash happens when a component has excess plastic on the parting line, a mold’s edge, or at any other spot where different shapes and regions meet.Common injection molding defects. The cause for this is severe thermal damage to the polymer melt.Plastic injection molding is a very cost-effective method for mass production of parts – but even the best designs sometimes have shortcomings that result in quality defects.Bewertungen: 4

13 Plastic Injection Molding Defects and How to Fix Them

In this step, reciprocating screw moves forward forcing the molten material inside the feed system and cavities of the mold. How to Fix: Lower temperature and injection speeds.In this blog, we will explore six common injection molding defects and discuss effective strategies to avoid them.Accurate detection of injection molding defects plays a crucial role in effective quality control of injection-molded products. KEYENCE’s Digital Microscope Analysis Examples website introduces new examples that change the conventional observation, analysis, and measurement performed with .

Common Plastic Injection Molding Defects & Solutions

Here are some common cosmetic defects that occur on plastic injection-molded parts, and tips on how to avoid them.Delamination in plastic injection-molded parts refers to the peeling of surface layers. Brittleness may be caused by overly dry conditions, by the overuse of recycled materials, . Warping manifests as uneven deformation due to uneven cooling or non-uniform mold design. Experienced operators understand the nuances of machine operation, mold intricacies, . Nonetheless, the influence extends to other regions of the area.Blistering and burn marks are two common defects associated with injection molding. Read on for a list of common injection molding defects, why they occur and how to troubleshoot them: Brittleness: The mold does not have suitable strength, and will easily crack or break. As its name implies, sink . Avoid Sink in Molded Parts.Defects are irregularities or flaws in plastic parts produced by injection molding methods, which can affect the part’s appearance, functionality, and structural . Sufficient draft is an important part of any mold design, and quick-turn tooling is no exception. What Are the Most Common Injection Molding Defects? 2. In the next section, we’ll see how you can avoid each of them by following good . Burn marks – Often appears .Plastic Injection Molding Defects — And How to Avoid Them.Mold clamp-up: injection unit approach and contact with the mold. Splay appears as a surface-level light or white streak on . Adjust the mold opening speed and pressure to .

Preventing Injection Molding Defects

On molded plastic pieces, burn marks are black or rust-colored discolorations. These defects are especially concerning as they can impact both the aesthetics and functional aspects of the final product. Both of these can damage the appearance and strength of the final product.Injection mold construction is the process of creating molds that are used to perform injection molding operations using an injection molding machine. So keep reading to . Defects may also be prevented by replacing . (2) Check the size of the exhaust port.Injection molding issues and defects can be caused by a host of reasons, including poor design, production process mistakes, quality control failures, and more.

6 Common Injection Molding Defects and How to Avoid Them

A thin layer of plastic is formed by excess .

Injection Moulding Process

1 Design Rules. 2) Increase the injection pressure. A thorough understanding of design, process parameters, material selection, and mold maintenance is critical for ensuring the production of defect-free and high-quality parts. Burn marks do not affect part integrity unless the plastic is damaged. Flashing is often the most common occurrence on the separating line of plastic molding. With advancements in Computer-Aided Engineering (CAE) technology, many factors that could lead to product defects have been eliminated, reducing the costs associated with trial runs during the . Splay appears as a surface-level light or white streak on the plastic.

The Twenty Most Common Injection Molding Defects

1 Molding defects and countermeasures. Warpage and deformation are distortions that occur in an injection molded part, causing it to deviate from its intended shape or design. The solutions, therefore, are to reduce both the resin temperature . Following are the commonly found injection molding defects .

How to avoid common defects in injection molding

This defect typically occurs along the edges or seams of molded parts, particularly in areas where two halves of the mold come together, known as the parting line. Defects in injection molding gates can occur due to various factors, including gate design, material properties, process conditions, and mold configuration. It is important to be familiar with these defects in order to identify and trouble-shoot them, as well as avoid them by developing a competent design! Below are the top . Trials are often performed before full production runs in an effort to predict defects and determine the appropriate . In actual production applications, many other injection molding . There are many rules for designing molds. (About 5/1000 mm) 6) Increase the runner or gate size.Despite its popularity and efficiency, injection molding can encounter various defects that may affect product quality, performance, and cost-effectiveness.This section explains the observation, analysis, and measurement of various defects in molded resin (plastic) products, bubbles in molding materials, and filler dispersion. Burn Marks: One of the most common injection molding defects is “burn marks.

4 Understanding the Basics of the Injection Mold

Molding Defects and Countermeasures

Flow Lines Or Flow Marks. These are generally .Here are some common cosmetic defects that occur on plastic injection-moulded parts, and tips on how to avoid them. During the injection . Vertical walls, meaning those part surfaces parallel to the direction of mold operation, should have a minimum draft angle of a 1/2 degree, and 2 degrees is even better; heavily textured surfaces may require 5 degrees or .When an injection molded part has jetting defect, it will automatically become weaker due to the defect’s flow pattern. Here is a list of defects to keep in mind while designing a part for injection molding.

Injection Molding Defects: Causes and Solutions

Excessive processing pressure, too fast speed, more filling materials, too long injection and pressure holding time will cause excessive internal stress and cracking.

While they seldom affect part quality, prevention involves adjusting injection parameters or incorporating gas vents. Most defects in injection molding are related to either the flow of the melted material or its non-uniform cooling rate during solidification.These injection molding defects are numerous and arise from various causes, possibly involving mold design, injection molding operations, raw material issues, and other factors. Injection molding, also known as injection moulding, is a manufacturing method that involves injecting molten material into a mold to produce various products. (3) Cleaning the mold surface.Defect 6: Warpage and Deformation. Whether you are an industry expert or a newcomer to the field, understanding these defects and their prevention methods will help you optimize your injection molding processes and ensure high-quality production.The severity of injection molding defect depends upon molding defect type, its position, and that part application. Defect: Cause: Solution: Gate vestige or gate mark: Large gate size or improper gate shape – Use a smaller gate size or change the . The injection pressure, injection speed, injection temperature profile, and shot size need to be controlled. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold. Machine: Set the machine of the appropriate size process: (1) Increase the injection time and reduce the injection speed.Common Injection Molding Defects and Solutions. What it is: Flow lines (also called flow marks) are waves, streaks, or lines that are discoloured when compared to the area surrounding them. However, some machine hardware changes are usually required to process .Injection molding is the most commonly used manufacturing process for the fabrication of plastic parts. The two most common causes are 1) excessive heating of the plastic resin before injection and 2) injection speeds that are too fast, which can trap hot air in the mold.One of the most common injection molding defects is Splay, also referred to as “silver streaks” or “jetting”. If you’re looking for a way to identify this common plastic injection molding defect and solve it in time, this guide will take you through the defect, its identification, and troubleshooting methods. These rules and standard practices are based on logic, past experience, convenience, and economy. How to Identify and Troubleshoot Injection Molding Defects? The injection molding process is . Charred streaks occur in the form of silver, light-brown to very dark discolorations on the surface of the molded part. These are usually observed . As injection molding offers high repeatability, design flexibility and low unit cost, it’s no surprise that most plastic parts you find around you .

Avoid Drag in Molded Parts. Introduce gas vents and gates.Plastic injection molding is a widely used manufacturing process, however, it sometimes leads to some common defects that affect the quality of the final plastic part.Defects in injection molding can result from various factors, including issues with the material, design flaws, or manufacturing process issues. 1) Increase the resin amount.

Injection Molding Defects and How to Prevent Them

Defects and solutions in injection molding gate.

To get the best results in injection molding, it’s crucial to understand these defects and how to mitigate or prevent them.Defect Resolution of Injection Molding. We cannot assume that an injection molding factory with defects is not a good company, because defects are almost inevitable in all injection molding . This paper presents a U-Net training strategy, namely Semi-Supervised Auxiliary Learning (SSAL), that incorporates the morphological information of the inspected products into the U-Net network.Preventing plastic injection molded part defects can be as simple as correcting the injection molding process. Operator Training and Expertise. Avoid Sink in Moulded Parts. 4) Increase the cylinder temperature.Injection molding flash, often referred to as “burrs” or “excess material,” is an unwanted protrusion on the final molded part. Product failure, .Remedies: Mold design: (1) Reasonably design the mold to ensure that the mold can be closed when the mold is closed.

Warping: When Plastic Takes a Twist.Injection molding is the go-to process for creating high quantities of plastic parts. 5) Provide a vent for the unfilled portion.

- Iniciar Sesion En Hbo _ Sign in with account email

- Insel Poseritz Kransdorf , Poseritz auf Rügen: Tipps für Deinen nächsten Urlaub

- Infrarot Kochplatte Nachteile | Kochplatten Ratgeber

- Infusionsdauer | Infusion legen: Vorbereitung, Durchführung, Komplikationen

- Inhaltsverzeichnis Ohne Seitenzahl Aktivieren

- Innsbruck Klima – Klima Innsbruck (Innenstadt): Klimatabelle

- Inkontinenzprotokolle Tabelle , Miktionsprotokoll Vorlage zum Ausdrucken (PDF)

- Innogy Zählerstand Einstellen | Westenergie Metering GmbH

- Ing Diba Kontaktlos Bezahlen : ING Kreditkarte + Girokonto: alle Vorteile, Nachteile & Erfahrungen

- Inglewood Arena Clippers | Clippers announce 2026 NBA All-Star Weekend at new Intuit Dome

- Inline Vs Online Vs Atline | Inline-/Offline-Messung