Laser Vapor Deposition Process

Di: Luke

Laser chemical vapor deposition

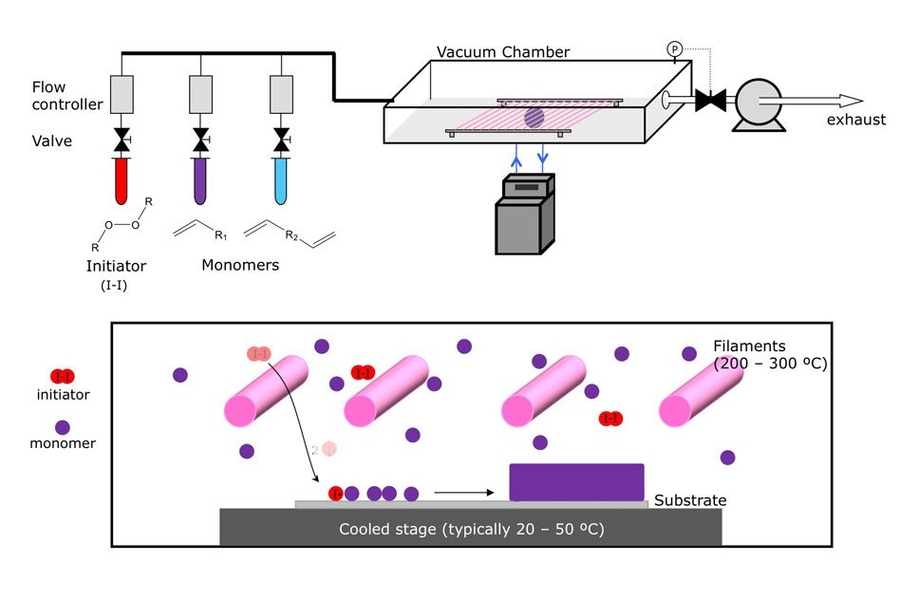

Pulsed Laser Deposition is a process which involves focusing of a high intensity pulsed laser beam on the source material to be deposited on a substrate inside a chamber under high vacuum condition. CVD is commonly used to deposit conformal films to surfaces essential in the manufacture of semiconductors and . Then, a via dielectric is deposited. The unique aspects of pyrolytic and photolytic laser chemical vapour deposition have been stressed.Geschätzte Lesezeit: 3 min

Chemical vapour deposition

Pulsed laser deposition is a physical vapor deposition technique in which a high-energy laser is focused on a target material in a vacuum chamber and .Carbon-based materials (CBMs) such as graphene, carbon nanotubes (CNT), highly ordered pyrolytic graphite (HOPG), and pyrolytic carbon (PyC) have received a great deal of attention in recent years due to their unique electronic, optical, thermal, and mechanical properties. Normally, the substrate is directly and uniformly . Therefore, PLD is favorable for the stoichiometric deposition of materials.: physical vapour deposition) zusammenfasste.

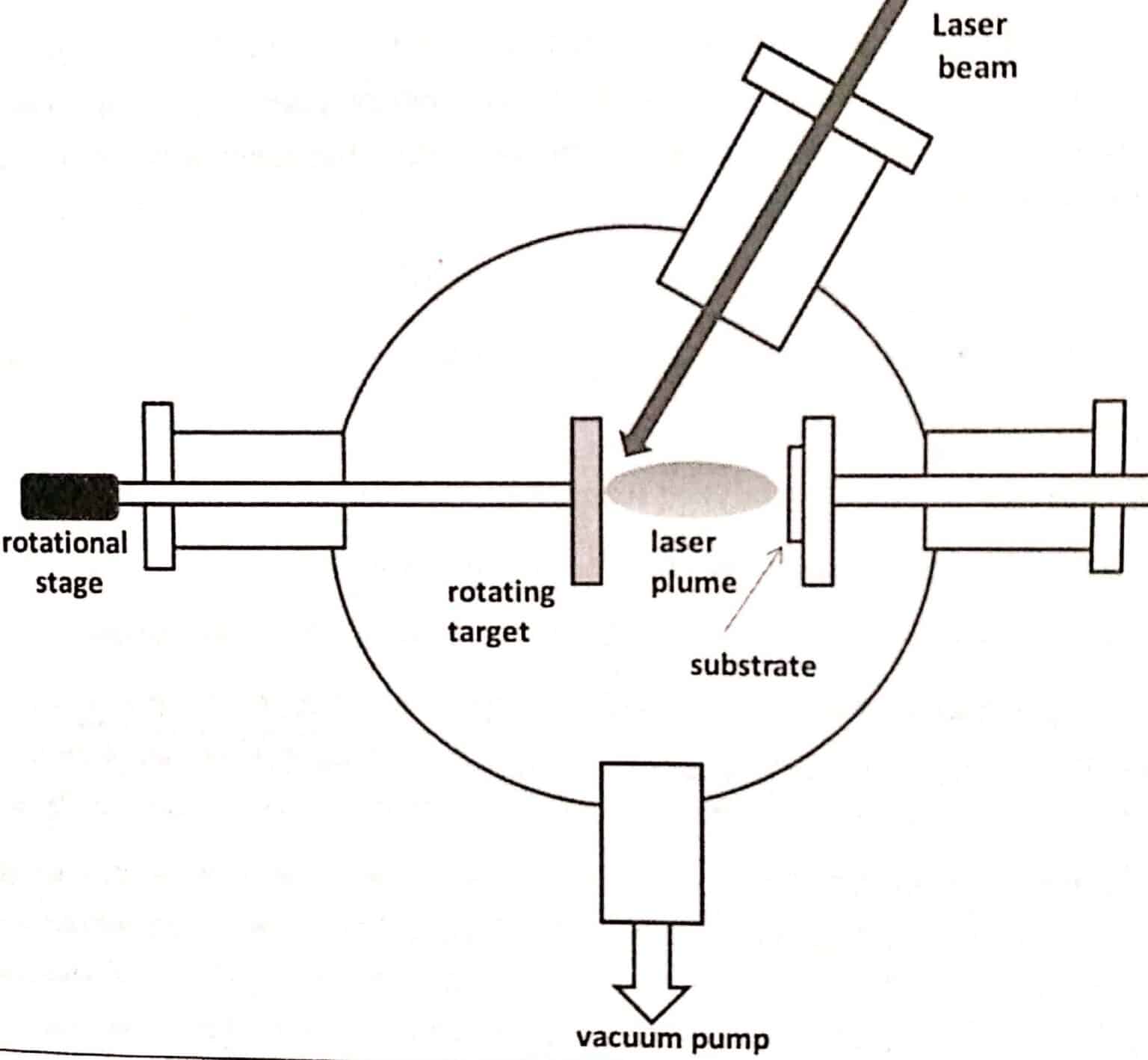

Pulsed Laser Deposition (PLD)

Der Begriff chemical vapour deposition wurde im Jahr 1960 von John M.Chemical vapour deposition (CVD) is a widely used materials processing technology in which thin films are formed on a heated substrate via a chemical reaction of .Laser chemical vapor deposition (LCVD) is a chemical process used to produce high purity, high performance films, fibers, and mechanical hardware (MEMS).Pulsed laser deposition: a high-power laser ablates material from the target into a vapor.Autor: Raja Nassar, Weizhong Dai

Research progress of laser-assisted chemical vapor deposition

Pulsed laser deposition is one of the multiple physical vapour deposition routes to fabricate thin films, employing laser energy to eject material from a target in the form of a plasma.3 Pulsed Laser Deposition. The technique is based on ion bombardment of a source material, the target.Laser chemical vapor deposition (LCVD) is a process by which an organometallic compound in the form of a precursor gas is induced, by light or heat from a laser . It is a form of chemical vapor deposition in which a laser beam is used to locally heat the semiconductor . the material to be deposited, start out in solid form, whereas in CVD, the precursors are introduced to the .

The deposition rates were significantly increased from 1 to 230 µm/h.

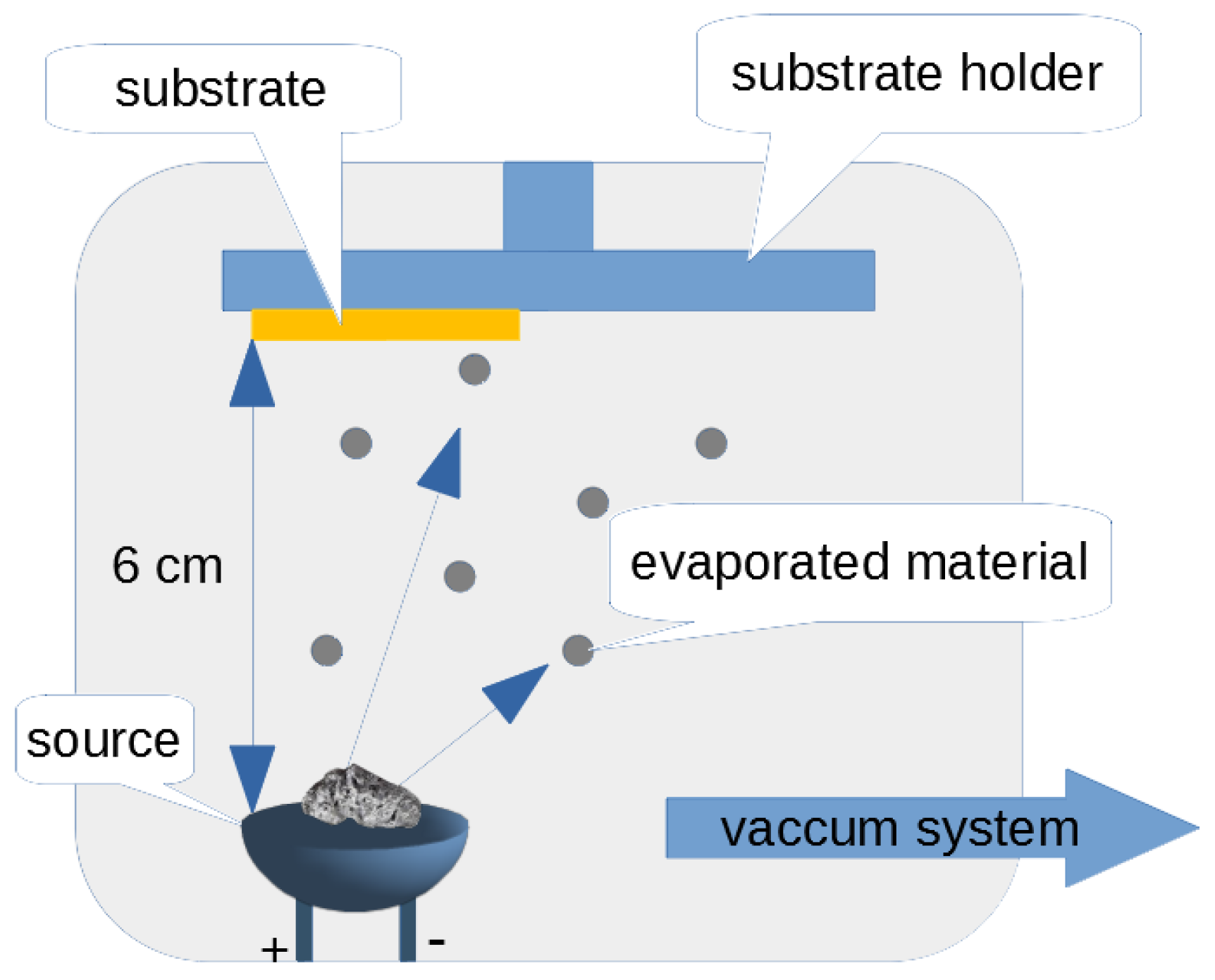

Physical vapor deposition

Chemical vapor deposition ( CVD) is a vacuum deposition method used to produce high-quality, and high-performance, solid materials.Laser vaporization cutting is a type of laser cutting that heats the surface temperature of a material so rapidly that the material avoids melting and instead, boils .Laser chemical vapor deposition (LCVD) technology has its unique advantages in reducing deposition temperatures, enhancing film purity and directly writing complex thin film patterns compared with conventional chemical vapor deposition (CVD).PVD is a deposition method that involves high-temperature vacuum evaporation and sputtering.LCVD is a chemical vapor deposition (CVD) process for the localized deposition of thin films. The process is often used in the .Diese Technik wird als Laserstrahlverdampfen (englisch: Pulsed Laser Deposition) bezeichnet.The special role of lasers in material processing is outlined in this article. Compared to alternative deposition processes, the PLD offers more excellent benefits such as adaptability, control over the growth rate, stoichiometric transfer, and an infinite degree of freedom in the ablation . However, the deposition rate is generally limited to nanometer or even . The process is in some respects similar to CVD, except that in PVD the precursors, i. Physical vapor deposition (PVD) is referred to deposition processes of thin films and nanostructures through the evaporation of solid precursors into their vapor phase by physical approaches followed by the condensation of the vapor phase on substrates.Plasma enhanced chemical vapor deposition is considered to be a special form of chemical vapor deposition (CVD). It is a synthesis process capable of producing high-purity, high-performance solid materials through chemical reactions in vapor phase.

Chemical Vapor Deposition

Laser chemical vapor deposition (LCVD) is one of several recently developed deposition techniques using laser sources. Pulsed Laser Deposition [21], Molecular Beam Epitaxy [22], Physical Vapor Deposition [23], and Magnetron Sputtering [24] are examples of . The process of PLD is well suited . Taking the reduction approach, chemical, thermal, microwave and laser reduction methods have been applied to prepare graphene from graphene .This study aims to select a suitable process and composition for the fabrication of a functionally graded GH4169/K417G superalloy by laser metal deposition (LMD).Mit diesem Begriff sollte die chemische Gasphasenabscheidung von physikalischen Beschichtungsverfahren unterschieden werden, die John Blocher unter dem Begriff PVD (engl.1,2 In contrast to . Ion bombardment results in a vapor due to a purely physical process, i. The chemical deposition is supported only by a plasma.SURFACE AND THREE-DIMENSIONAL PROCESSING BY LASER CHEMICAL VAPOR DEPOSITION .Autor: Luzhao Sun, Guowen Yuan, Libo Gao, Jieun Yang, Manish Chhowalla, Meysam Heydari Gharahcheshmeh, Kare. The whole process consists of three stages: (1) evaporation of the solid source .

A practical guide to pulsed laser deposition

In the standard procedure the chemical reaction is thermally activated near or on the hot surface of the substrate, where deposition takes place.Laser-assisted chemical vapor deposition was used to grow the layers in a few seconds. They are then applied to a substrate as thin films.Prior to the LR process, NPs had to be synthesized by chemical or mechanical processes which are time, cost and energy consuming [13], [14], [15]. Laser Chemical Vapor Deposition (LCVD), on the other hand, does not require the pre-synthesis of nanomaterials. This investigation . A substrate, commonly a single-crystal oxide, is placed in the path of the plume and acts as a template for the arriving species from the target to coalesce and self .In contrast to this standard CVD technique, laser-induced chemical vapor deposition (LCVD) allows local deposition of materials within the focus of a laser.The laser parameters are mainly influenced by the dominating mechanism, i.An overview of a Chemical vapor deposition process [31] .Laser chemical vapour deposition (LCVD) is a new manufacturing process that holds great potential for the production of small and complex metal and ceramic .Yttria-stabilized zirconia (YSZ) films were prepared by a laser Chemical vapor deposition (CVD) process. A plasma-like strong light emission was observed from a reaction zone around a substrate by laser irradiation.Pulsed Laser Deposition (PLD): PLD involves the use of a high-power pulsed laser to vaporize the target material, resulting in a highly energetic and reactive . A universal process parameter was optimized through an orthogonal test, and the influence of the preheated substrate temperature on the residual stress was investigated.

Pulsed laser deposition (PLD) is a physical vapor deposition technique that relies on the interaction between a high-power pulsed laser beam and the surface of a target material, which in most cases is a solid.These techniques include chemical vapor deposition, vacuum evaporation, sputtering, spray pyrolysis, and Pulsed laser deposition (PLD).

Laser Chemical Vapor Deposition

Abstract To enhance the corrosion and wear resistance of biological titanium alloy Ti6Al4V in the human body, plasma nitriding + plasma enhanced chemical vapor deposition (PN + PECVD), laser remelting (LR) process were employed to modify the titanium alloy, respectively.Physical vapor deposition (PVD) is a vaporization coating technique, involving the transfer of material on an atomic level under vacuum conditions. The resulting solid material is in the form of a thin film, powder, or single crystal. The microhardness of LR and PN + PECVD samples was .

Physical Vapor Deposition (PVD)

CBMs have been grown using a variety of processes, including . The LCVD system consists of a chamber with inlets for reagent gases.

Abstract Laser chemical vapour deposition (LCVD) is a new manufacturing process that holds great potential for the production of small and complex metal and ceramic parts., plasma and vapor are generated (thermal evaporation process) when the high energy density of short-pulse lasers is .Laser chemical vapor deposition (LCVD) is a promising method for selective deposition of solid materials via localized chemical vapor reaction driven by a laser beam. Thermal laser epitaxy: a continuous-wave laser evaporates individual, free-standing . These deposition methods are up-scalable, involve a controlled solvent-free environment, have the ability to conformally coat rough substrates, involve soft, low-energy deposition conditions, are compatible with shadow masks for . In the background of the various chemical vapour deposition processes, the laser-induced chemical vapour deposition processes have been described. Mit Hilfe eines fein fokussierten Laserstrahls können kleinste .Pulsed laser deposition (PLD) can be used to vaporize and ablate all type of solids including metals [ 11, 12, 13 ], semiconductors [ 14 ], insulators [ 15 ], and for the .Pulsed laser deposition (PLD) is a commonly utilized technology for growing thin films in academia and industry. An etch step then forms a . The charges in the light-emitting zone .Schematic of the laser-driven chemical vapor deposition process. As the laser light is focused on a .

Max-Planck-Institut fur .Pulsed laser deposition (PLD) is a commonly utilized technology for growing thin lms in academia and industry. The difference between these processes stem principally from the fact that not only uncharged particles but also charged ones (ions, electrons) are present in plasma.Chemical vapor deposition (CVD) is parent to a family of processes whereby a solid material is deposited from a vapor by a chemical reaction occurring on or in the vicinity of a normally heated substrate surface. Hence, this technique is part of the class of physical vapor deposition . PLD evaporates and ionizes the material through one or a series of high energy laser pulses. The two predominant characteristics of a laser .Vapor-based processes are particularly promising to deposit the perovskite thin film absorber of solar cells.Physical vapour deposition processes with the presence of plasma possess many specific features which are not present in non-ionized gas crystallisation processes. • The effect of process parameters on graphene growth was discussed.Autor: Khalid Bin Masood, Pushpendra Kumar, Mushtaq Ahmad Malik, Jai Singh

Laser Chemical Vapor Deposition

Another critical capability of the LCVD technology, harnessed through . Laser-driven chemical vapor deposition for high-performance fibers and powders Celebrating 100 years in both amorphous and nanocrystalline states by using different precursor gases.

Plasma-Enhanced Chemical Vapor Deposition (PECVD)

Laser chemical vapor deposition (LCVD) uses a focused laser beam to locally heat the substrate and drive the CVD deposition reacton. Die Geschichte des . Compared to alternative deposition processes, the PLD oers more excellent benets such as adaptability, control over the growth rate, stoichiometric transfer, and an innite degree of freedom in the ablation geometry.

In this process, a structure undergoes a diffusion barrier etch step. This technology has been widely applied in thin film deposition and attracted growing . • This cost effective method could facilitate the integration of graphene in electronic devices.Pulsed laser deposition (PLD) is a physical vapor deposition (PVD) technique where a high-power pulsed laser beam is focused inside a vacuum chamber to strike a target of . Chemical vapor deposition (CVD) is a widely used technique for the production of thin films of metals, semiconductors, and insulators [1]. This source material is ejected as a plasma plume from the target. Laser vaporization offers a precise means of treating mouth lesions that reduces the potential for pain and scarring. The problem of compositional changes often encountered with evaporation processes practically does not arise.

Laserablation

The deposition temperatures are usually between 100 and 600 °C. the sputtering of the target material. The area onto which the laser beam is focused undergoes several transformations that involve heating, melting, and/or local . The plasma serves as an activation for the reaction of the reactive gases.Most of these microelectronics-focused methods yield deposition rates that range from tens to several hundreds of microns thickness per hour. Physical vapor deposition has been the workhorse of the back-end-of-line for the copper damascene process. By varying experimental conditions, including .

Laser Vaporization of Mouth Lesions

Sputter deposition is a widely used technique to deposit thin films on substrates.The most popular processing methods include epitaxial growth, liquid phase chemical/electrochemical exfoliation, mechanical exfoliation, chemical vapor deposition and laser-assisted synthesis. Several different deposition reactions and substrates have been examined as a function of intensity and irradiation time using a CO 2 laser source: Ni on SiO 2, TiO 2 on SiO 2, TiC on SiO 2, .Chemical vapor deposition (CVD) is a widely used materials-processing technology.

- Längen Umrechnen 5 Klasse , Größen und Maßeinheiten Mathematik

- Laser Ästhetik Permanent Make Up

- Langhans Riesenzellen Anatomie

- Laptop Formatieren Und Neu Aufsetzen

- Larnaca Hotels Near Beach _ THE 10 CLOSEST Hotels to The Golden Bay Beach Hotel, Pyla

- Lasten Über Personen Sicherheitsniveau

- Lappland Glasiglu – Igloo hotel Finland

- Laub Aufnehmen Mit Bürsten – Die besten Laubsammler: Gartenarbeit neu gedacht

- Last Chance U Basketball Professional Team

- Langzeitkrank Urlaubsanspruch _ Urlaubsanspruch bei Krankheit: Das gilt

- Largest Airlines In North America

- Lasergravur Oder Beschriftung , Lasergravuren & Laserbeschriftung

- Latex Symbol Finder : How/Where to find such special symbol/character?

- Lateinisch Erde 10 Buchstaben , LATEINISCH: ERDE