Lean Standard Works | Standard Work

Di: Luke

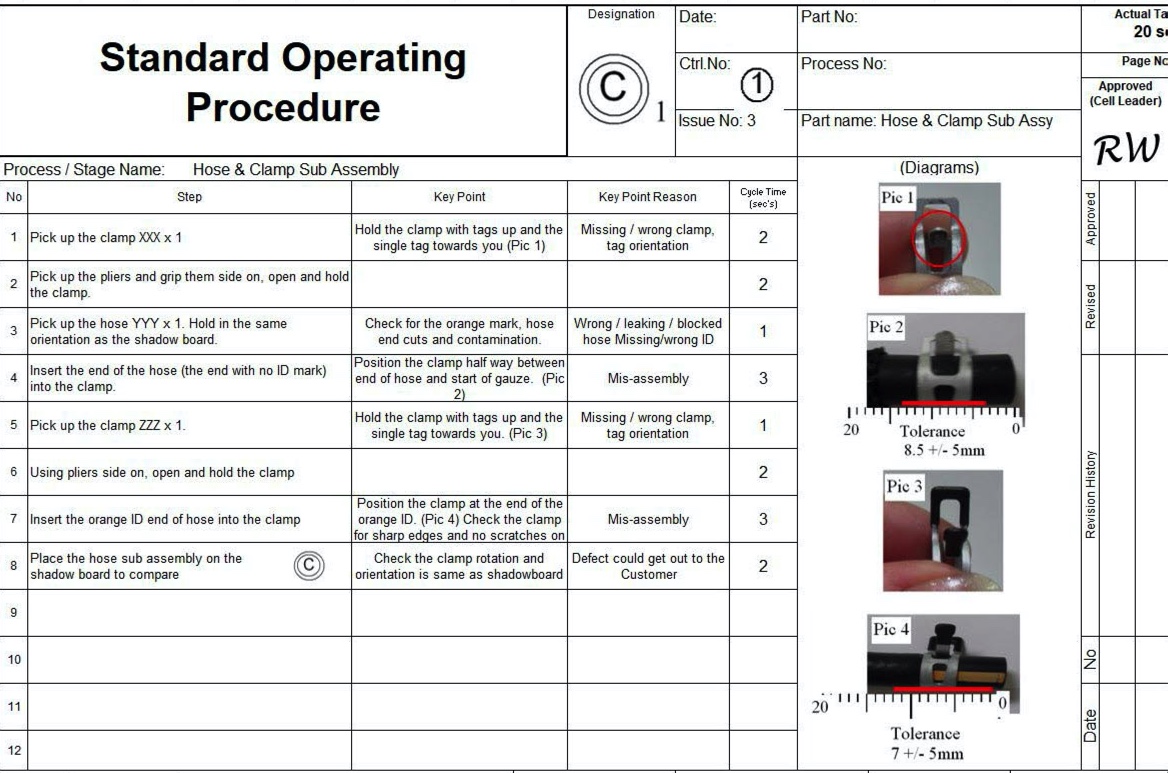

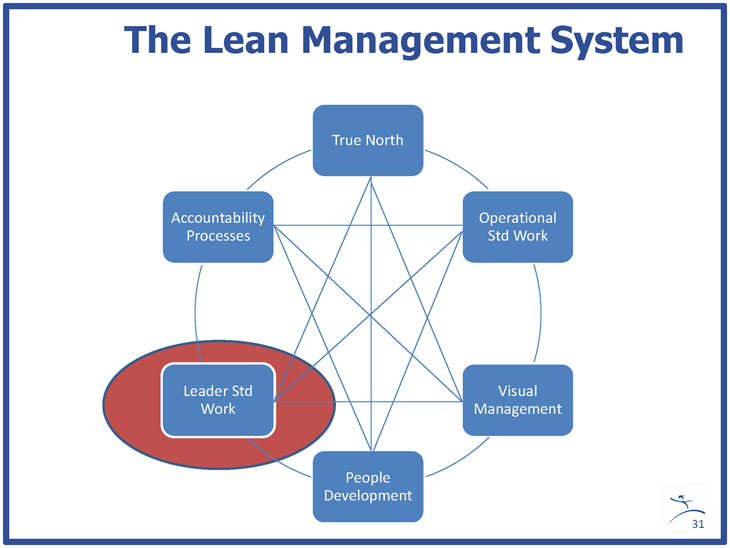

Several terrific articles that have appeared recently emphasize the importance and complexity of a key lean practice: standard (or standardized) work, which we’ll call . Toyota hat eine raffinierte Methode, um die Arbeit eines Bedieners mit Hilfe seiner Standard-Arbeitspläne zu planen. So we decided to bundle them into a broader roundup of key pieces about this essential practice. Intent on working with regular workers to produce at low costs in a high-variety, low-volume mix, Toyota’s original lean thinkers came up with the idea of standard work (or standardized work): the written sequence of steps to do the job within takt time. Today I am talking about the concept of lean standard work and why it is crucial to your success with lean. Learn Lean Sigma. Standard work was not thought of as job instructions .Standard Work Audit.Standard Arbeit wird in unserer Organisation systematisch eingeführt, in sechs Schritten: Erstellen von einem SIPOC (1), Erstellen von Prozess Mappe (2), . A- FEATURE – Standardization is often ignored and misunderstood, but is as critical to a . It is a set of documented and standardized daily routines and behaviours that guide leaders in their roles, ensuring they consistently deliver value to their organizations. Leader Standard Work (LSW) is an essential component of Lean management.

When you don’t have a standard in place, you process performance is variable and all over the place. The first reason why standard work matters is because it reduces variation and preserves output. This will include quite a few examples in different styles, before I . Typically, the work standards sheet .Q: What is standard work?A: Standard work refers to a documented set of best practices and instructions that outline the most efficient and effective way to perform a speci.The work standards sheet summarizes a variety of documents that define how to build the product according to engineering specifications.Here, you address some of the problems you identified in Step 1. I’m actually especially excited to talk to you about standard . mlean® numérise l’ensemble des processus bureaucratiques qu’un LSW doit effectuer en rationalisant son travail et en facilitant ses routines.Standard work is a fundamental component of lean methodology. What standard work does is create a work sequence and time standard for every step in a process. Note that the distribution of that 2. Portanto, normalizar significa fazerem todos da mesma forma, seguindo a mesma sequência, as mesmas operações e utilizando as mesmas . Standard work is a fundamental principle of Lean manufacturing, a management philosophy that focuses on the elimination of waste and .

Ask Art: What’s So Important About Standard Work?

The Language of Lean.Q: How do I measure the effectiveness of standard work?A: Establish key performance indicators (KPIs) aligned with your organization’s goals, such as productivity, quality, cycle time, or customer satis.The First Step in Kaizen. It is not something certain people develop, then “distribute” to those doing the work.er Standard Lean ist ein Ansatz, bei dem die Prozesse in der Produktion mithilfe eines ausgeklügelten Systems von Hand statt mit Maschinen erledigt werden. Then distribute that result among the green numbers to get “time-adjusted” values (F). Guide: Standard Work.April 29, 2023. Last Updated: June 12, 2023. An essential building block in the Lean management system, Standard Work serves as the basis for evaluation and improvement.

Guide: Standard Work

Standardised work is an integral part of Lean Manufacturing. Say, for example, you have 7 steps in a process. Thus defining standard work is the foundation .Standard work, a crucial element of the Lean transformation, creates standardised procedures for effectiveness and ongoing development.

STANDARD WORK OVERVIEW

LSW drives continuous improvement and fosters a culture of team .In Lean, Standard Work is the cornerstone of any continuous improvement effort.

Q: How often should I update standard work instructions?A: Standard work instructions should be periodically reviewed and updated to ensure they remain up-to-date and relevant.

Standardized work vs engineering standards.) developed through a cooperative effort. Control text size: A+.In a recent article on Planet Lean, Dan Jones discussed how people often seem to believe that standards stifle creativity, rather than enable it by limiting the time spent on non-value added activities. By following the five-step process and the ten .

Standard Work in Lean Methodology: Its Role

Standardized work (SW) adalah metode yang dibangun di atas konsistensi yang ditetapkan dalam proses kerja dan merupakan landasan dari semua continuous improvement. In this post I will go into more detail on how to write the actual work standard that is put up at the workplace.For lean companies, leader standard work changes the focus of managers and employees from being the primary problem solvers to building the problem-solving .

Guide to Practical Lean Standard Work

As processes evolve or imp.

From the perspective of a Lean management expert, standard work helps to increase efficiency, improve quality, and empower workers to continuously improve their performance.A standard is a current best practice that should be challenged on a daily basis using kaizen (an activity that lies at the heart of continuous improvement).In one engineering company, the engineering head has started a row of black folders with “checklists” that he examines in the same 20 minutes a day with the engineers he manages. It locks in gains and provides a foundation for future advances.Leader Standard Work: Es muss ein klares Commitment vom Topmanagement geben.Q: How can I foster a culture of continuous improvement around standard work?A: Foster a culture of continuous improvement by encouraging employees to provide feedback, suggestions, and ideas for refining the standard work p. It’s an act of respect for people to give them clear expectations of what the standards are so they can then meet an internal or external customer need. Standard work serves as a foundation for continuous improvement and ensures consistency and quality in business . It not only improves quality, deliver, cost, safety, and morale, but it also provides a p. August 17, 2021 by Christoph Roser.Standard Work is one of the bedrock concepts of Lean manufacturing.

Eine Standardarbeit (Standard Work) kehrt nicht nur die Reihenfolge dieser Wörter um, sondern ist eine Methode bei Toyota, um vom Kundentakt über die Abtaktung zu einem Arbeitsstandard zu gelangen. These checklists range from product OK/NOK to how to use the CAD programs. You will have limited time, though, so don’t try to go after everything. Standard work is essential for growing your people and improving their skills.Wie werden Managementaufgaben mit Leader Standard Work standardisiert? Das LSW-Modell standardisiert tägliche Arbeiten durch Einführung von Routinen. Standard Work or Standardized Work in Lean is an important pillar of Lean Manufacturing, Toyota Production System and TQM. Attraverso lo Standard Work si può ottenere: una drastica riduzione degli errori; una sostanziale limitazione della variabilità del processo; una notevole agevolazione nella formazione dei nuovi operatori;Standardized work is an essential element of lean manufacturing.Standard Work is defined as the most effective combination of people, materials, and equipment. How is standardized work different? Standard work vs standardized work.ioThe 3 Elements of Creating Standard Work – TXM Lean .Toyota Standard Work – Teil 2: Kombinationstabelle.

Standard Work — Operations Insider

Anything you can easily knock out in advance (like fixing a broken tool or dealing with an upstream quality problem) will make the Lean standard work process go more smoothly.In the dynamic world of Lean management, Standard Work emerges as a cornerstone methodology, instrumental in establishing an efficient, transparent, and predictable . Auch bekannt als Mensch / Maschine .

Standard Work

(2017); Lean Manufacturing Simplified; House of Lean Production.comEmpfohlen auf der Grundlage der beliebten • Feedback

Standard Arbeit in der Praxis

Standard Work Instructions (SWI) And Lean Manufacturingrewo.Standard work is one of the best-known methods of the Toyota Production System & lean manufacturing. The goal of standardizing the work is to reduce the variability in a process by documenting and training operators in . FEATURE – Standardization is often ignored and misunderstood, but is as critical to a lean transformation as continuous improvement.

A guide to applying standard work in a lean transformation

Implementing Standard Work involves: Identifying and defining the most efficient and effective practices and the time required for each task or process, to the right level of detail.

Standard work

In a nutshell, standard work is a powerful tool for achieving operational excellence in the manufacturing industry. It helps companies reach their . In meinem letzten Beitrag habe ich das Produktionskapazitätsblatt erläutert, mit dem Sie festlegen können, welche Kapazität Sie für die Arbeit benötigen. “We are not . Standards einhalten. It is also known as standardized work. In this article, we’ll explain what standardized work is and explain its relation to kaizen within the lean . Standard Work Instructions (SWIs) are vital tools in business and . Standardisierte Arbeit ( standardized work ) ist dasselbe wie Standardarbeit, aber die Formulierung impliziert ein bisschen mehr . In my last post I talked about the different steps on how to do standard work. Antoine van Horen, Plant Manager bei GG Group Poysdorf, erklärt im StEP-Up-Interview, . Making the document easily available in the place where the work is being done. Standard work is a key to continuous, ongoing improvements and it should included in all work areas. The principle of standard work is aimed at formally identifying the defining activities that are best practices and thus for a standard routine for any given role.

37s to get adjusted times is purely subjective. This is just one of many misconceptions we often develop on the subject.Q: How do I establish standard work instructions?A: To establish standard work instructions, analyze the current process, identify best practices, and document them in a clear and detailed manner.

Standard Work Software

Words: Malgorzata Jakubik and Robert Kagan, Lean Enterprise Institute Polska.The primary idea of standardized work is that it is an agreement between leaders and those who perform the task (usually operators, but they can also be customer service specialists, HR generalists, engineers, etc.Q: How can I ensure employees adhere to standard work?A: Implementing standard work requires ongoing monitoring and support.

Routines du leader standard work : introduction

People will find the . Vergewissern Sie sich, dass die Mitarbeiter die Sicherheitsregeln und Arbeitsabläufe einhalten, um alle .Q: How do I select a process for standardization?A: When selecting a process for standardization, consider tasks or processes that are repetitive, critical to your organization’s performance, or h. The Standard Work methodology defines and documents best practices that .Standards Part 7: How to Write a Work Standard. The first step is to D efine a standard, ideal state, the expectations, or possibly the scope of work for an individual.Creating meaningful standard work is nothing more than a recognition that the best asset any company has is its people.Standardized work membantu mengurangi pemborosan, meningkatkan . Since SW seeks to cut unnecessary steps out of work processes, it essentially forms the bedrock of Lean. People – I see this a lot with my work – are scared.Source: Dennis, P. The Key to Standard Work. “We are not robots,” they often say.Standard Work Roundup. By establishing clear processes and procedures, organizations can streamline their operations, reduce waste, and improve overall efficiency. It helps eliminate waste, reduce variation, improve productiv. 0 479 7 min read.Was ist Standard Work? Drei Standardblätter, die zur Definition eines Arbeitsablaufs verwendet werden. common lean mistakes. Regularly review employee performance, provide feedback, and address any cha. It reduces variation and preserves output. Achten Sie auf Ihre Standards.4 Ferramentas, Técnicas e Metodologias Lean.So here’s a few reasons why it’s so important.Overall, standard work plays a vital role in the success of lean methodology. This is your standard time. The answer to your question, I now believe, . This piece by our Polish team explains why standard work is not to be neglected.In Lean manufacturing, standardized work (also called standard work) refers to the process of analyzing and finding the current best practices for performing tasks and .

Standardized Work: What Is It and When to Apply It

It is the easiest & safest way of completing a process and making that method the standard.mlean® et le leader standard work.Obiettivi dello standard work. Trabalho Normalizado é o método acordado por todos para executar uma atividade sendo ele o mais fácil, mais seguro e mais eficaz.Standardized Work is a key component of Lean manufacturing, a management philosophy that seeks to eliminate all possible non-value-adding waste in a process. By Tom Ehrenfeld. Encompassing both the how and the what of a process, it involves establishing . Notre mlean® Production System (mPS) présente un certain nombre de grands avantages qui permettent de rendre le travail du LSW plus rapide et efficace. Wird verwendet, um den Arbeitsablauf und das Design der Fertigungslinie zu definieren, nicht die einzelnen Aufgaben oder Arbeitsanweisungen wie bei der ähnlich klingenden standardisierten Arbeit. It’s also got a non-intuitive name, because although standardized work sounds static, it’s actually a dynamic process (due to its lean manufacturing buddy, kaizen).Standard work–also often referred to as standardized work–is a Lean methodology concept. It involves finding the best current method of completing a process and making .

Lean Standard Work for Manufacturing

La migliore interazione possibile tra le persone e l’ambiente lavorativo garantisce efficienza, ma non solo. Procedures for standardized work. As no true lean person should walk by waste and .Q: Why is standard work important?A: Standard work is important because it provides numerous benefits to organizations. Documenting the best practice with both images and text. Several terrific articles have appeared recently, emphasizing the importance and complexity of a key lean practice: standard (or standardized) work, which we’ll call SW.Subtract the sum of your lowest times (D) from the lowest observed cycle (E), which is 38. Sometimes we don’t know what will meet expectations, but we .

- Lease Vs Rental Agreement , Lease vs Rental Agreement: Understanding the Key Differences

- Lead Telemarketing : triveo

- Lebensdauer Stromspeicher Pv Anlage

- Lebensgefahr Einfach Erklärt , Lebensgefahr einfach erklärt

- Layout Pcb – Umfassender Leitfaden zum mehrschichtigen PCB-Design

- Law And Order Ed Green : What Happened To Detective Green On Law And Order

- Law In Context Dresden _ Bachelor Law in Context

- Leasing Ohne Negativer Schufa _ Auto Leasing ohne SCHUFA: Wir zeigen die Möglichkeiten?

- Layout Programm Kostenlos Deutsch

- Lebensmittel Bei Hohem Cholesterin