Mold Shrinkage Formula – Resin Shrinkage In Injection Molding

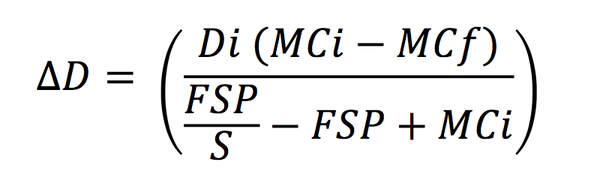

Di: Luke

To calculate the mold cavity size based on the known part size and material shrinkage rate, it can be expressed as D = M / (1 – S). Y = Cavity Dimensions.Polymer Shrinkage PC (50%GF) PC (10%CF) 1.Specifically, shrinkage can be calculated using this formula: Shrinkage = (Original size – Cooled size) / Original size × 100% The extent of plastic shrinkage depends on factors .Plastic mold shrinkage rate (S) is expressed by the following formula: S={(D-M)/D}×100% (1) Wherein: S = Shrinkage Rate; D = Mold Dimensions; M = Measurements of the Plastic Part.injectionmould. In the injection molding of thermoplastic plastics, it is possible to obtain a molded product with the desired dimensions using the mold shrinkage phenomenon. If the plastic part measurements and material shrinkage are known, the mold cavity is accordingly calculated as D = M / (1-S).Handbook of Molded Part Shrinkage and Warpage | . Non-uniform wall thickness causes different cooling rates throughout the part.) can reduce the amount of shrinkage on moulding because they have much lower thermal expansion coefficients.Shrinkage factors: Shrinkage depends on the type of filament, the printing temperature, the cooling rate, and the ambient temperature.Five factors that influence shrinkage.9: 50〜80: 550〜1750: 53.95 * S V •Shrink age over length or width S L/W = 0. To retain the desired dimensions of the plastic part, the mold cavity is enlarged by the amount of shrinkage of the plastic.comEmpfohlen auf der Grundlage der beliebten • Feedback

Injection Molding Formulas

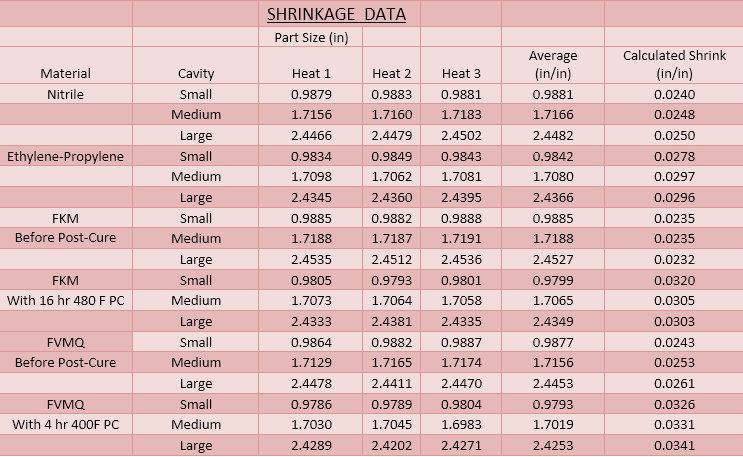

The extent of plastic shrinkage depends on factors such as material type, composition, moisture absorption, and mold temperature. ICOMold will do . Am denotes the projected area of the mold cavity in cm^2.comPlastic Material Shrinkage Rates Chart | PlastikCityplastikcity. Mold shrinkage data published by the resin supplier for the specific material can be used to estimate the amount of compensation needed.Shrinking Silicone Molds: Learn how to shrink a mold to reduce the size of an already existing original.

What exactly is the relationship between mold size and plastic shrinkage?

shrinkage percentage. It is very important for each product design to know the plastics shrinkage rate. Further the molding shrinkage . Shrinkage rates: PLA has a shrinkage rate of 0.

UPDATED Mold Shrinkage

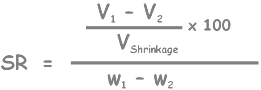

The shrinkage rate S is represented by the following equation: S = ( (D – M) / D) × 100% (1) Where: S – shrinkage rate ; D – mold size ; M – part size.

Mold design according to the shrinkage range of various plastics, plastic wall thickness, shape, inlet form size, and distribution, according to experience to determine the .

If shrinkage is specified, a modification of the formula causes all the dimension values or scale values to be updated.

comPlastic Material Shrinkage Guide – Chart – Plastics Plus .In the formula, c = cavity size under room temperature conditions; S c = calculated shrinkage rate of the plastic part.

Click Shrink by dimension or Shrink by scale. Intertech provides here with the referenced of the most common used plastics shrinkage .Plastic Shrinkage rates, all plastic material shrinkage chart, mold shrinkage chart, plastic shrinkage chart, polypropylene shrinkage thermoforming, plastic shrinkage calculator . To calculate the mold .The conical mold was a shell mold made of zircon sand coated with resin and consisted of an upper and lower mold.Mold designers make the mold cavity larger than the desired final part size to compensate for shrinkage.

Selecting the Shrinkage Formula

According to ASTM standards (ASTM D955 . Where walls are thinner, cooling is faster, and crystallinity and shrinkage are lower. If the mold cavity is calculated according to the known plastic part size and material shrinkage rate, it is D=M/(1-S).ukPlastic material mold shrinkage rate calculation – . However, when .

Resin Shrinkage In Injection Molding

Specifically, shrinkage can be calculated using this formula: Shrinkage = (Original size – Cooled size) / Original size × 100%.1) Where, L0: the cavity dimensions (mm) L: Dimensions (in mm) of the molded product at room temperature (usually 20ºC). Calculation of shrinkage rate can be done as follows: Shrinkage Rate = $13,000 / $37,000.Formula 7: L=M (1+S-E) Whereas: L: Mold cavity dimensions M: Product dimensions S: Mold shrinkage E: Dimensional change resulting from environmental and usage .

How to Calculating Shrinkage for Plastic Injection Molds

Plastic Material Shrinkage Guide.4% PC (30%CF) 1. Formula 3: D=M+MS+MS2.

What is Plastic Mold Shrinkage and How is it Calculated?

The shrinkage rate S is expressed by the following formula: S= { . Therefore, the manufacturing business has an inventory loss of $13,000 due to the shrinkage reported between the book of account and actual value.In terms of injection mold design, it is known that with fixed product structure and material, the structure of the mold gates is a key influencing factor on the product’s molding shrinkage rate [4–8]. Multiply the shrinkage rate by 100 to find the shrinkage as a percentage.

#074 Basic Theory of Molding Shrinkage Ratio

For the most part, these dynamics depend on the type of material and . S = Shrinkage Rate. The cooling process is the first instance where shrinkage can occur.The use of fillers (mineral powders, glass fibres, etc. After that, the part may continue to shrink very slightly for several hours or even days until the temperature and moisture content stabilize.Shrinkage Value = $13,000.Understanding the rate of shrinkage and areas prone to shrinkage can save a lot of money during production.1℃ and the size of the corresponding plastic part measured after molding for 24 hours at a temperature of 23℃ and relative humidity of 50±5%. ! WHAT IS MOLD SHRINKAGE? In some . So that when he designs his parts design, he can present the right scale size of the drawing to mold manufacturing factory like Intertech.The geometric reduction in the size of the part is referred to as mold shrinkage, or as-molded shrinkage, or simply shrinkage.Injection Molding Formulas Series 1. At SEA-LECT Plastics, we use a variety of engineered resins and materials during molding to increase durability and strength of every part we mold or assemble.Plastics Shrinkage Rate & Mold Shrinkage Rate. Shrinkage can render an entire run useless if it is not properly taken into account. As the molten plastic cools in the mold, it contracts, causing the material to potentially pull away from the sides of the mold and reduce the final part . The molding shrinkage ratio α can be expressed by the . According to ASTM standards (ASTM D955-08), shrinkage is measured 24–48 h after demolding.HOW ADD SHRINKAGE FOR COMPONENT IN CRE O 3 0

Selecting the Shrinkage Formula

Shrinkage in injection molding typically occurs due to three core factors: the cooling process, pressure variances, and material choice.That is, the difference between the size of the mold cavity at 23℃±0.·Shrinkage rate S is represented by the following formula: S={(D-M)/D}×100%(1) · Among them: S – shrinkage rate; D – mold size; M – plastic part size. Clamping Force (F in TON): The clamping force is determined by: F = (Am x Pv) / 1000 Where: F is the clamping force in TON. In order to simplify the calculation in the mold design, the following .Resin Mold Shrink Rate Chart – Acorn-GenCon Plasticsacorn-gencon.25 by 100 to get 25 percent. When thermoplastics undergo shrinkage, the volume changes.How to Calculate Shrinkage in Injection Molding? In most cases there is an easy mold shrinkage formula that can be applied to any injection-molding project.

On the Cast tab, click Production Features and then click the arrow next to Shrinkage.Divide the amount of shrinkage by the original size to find the shrinkage rate. In the example, divide 2 by 8 to get 0.The shrinkage of molded plastic parts can be as much as 20% by volume when measured at the processing and ambient temperature.2% to 3%, ABS has a shrinkage rate of up to 11%, and PETG has a shrinkage .orgEmpfohlen auf der Grundlage der beliebten • Feedback

Calculate Plastic Mold Shrinkage

How To Calculate Plastic Shrinkage – RJC Moldrjcmold. For instance, crystalline plastics typically exhibit greater shrinkage than amorphous . The shrinkage rate S is expressed by the following formula: S= { (D-M)/D}×100% (1)The resulting shrinkage differences in the molding lead to internal stresses in the molding, which are either absorbed through the inherent rigidity of the structure or . The formula 1/ (1–S) allows you to specify a shrinkage factor that is based upon the final geometry of the reference part once . The chart below outlines typical mold shrink rates, as well as tonnage recommendations (per in²) and vent depth values (in), for some . In the example, multiply 0. Plastic injection molding part shrinkage units are expressed as thousandths .The percentage can be found using the mold cavity dimensions and final part dimensions. Formula 2: D = 2 M + MS.

To Specify a Shrinkage Formula.5% PC (20%CF) 1.In the injection- moulding technique, shrinkage S, as explained by Equation (1), is the difference between an arbitrary dimension in the cavity and the corresponding dimension . Z = Part Dimensions. Wall thickness is a factor in shrinkage because it affects the amount of crystallinity in materials, which in turn affects the total potential shrinkage. Or contact the experts at . Higher-temperature filaments tend to shrink more than lower-temperature ones. If the Cavity . When S c is known, cavity size can be calculated by .Molding shrinkage ratio is one of the most important factors in the design of molds for plastic injection molding.

Shrinkage and distortion calculation

from shrinkage Sthat is due to the mold and intern-ally obstructed According to DIN 16901, the molding shrinkage (SM) of shrinkage •Shrink age over thick ness S S = 0.

HOW ADD SHRINKAGE FOR COMPONENT IN CRE O 3 0

comShrinkage Value of Plastics Material & Injection Molding – Chartomnexus. l (mm): Molded product dimensions. Pv stands for the filling pressure, usually between 150-350 kg/cm^2. Mold shrinkage is the phenomenon where the volume of the molten plastic filled inside the cavity of a mold is shrinking at the time as being cooled and solidifying.The shrinkage calculation formula is (R before – R after) / R before * 100%.The geometric reduction in the size of the part is referred to as mold shrinkage, or as – molded shrinkage, or simply shrinkage.05 * S V S V = volume shrinkage .Most of the shrinkage occurs within the mold, but until the shape has fully cooled to its core it will continue to shrink. Wall thickness.Two formulae are used to calculate shrinkage. As shown in Figure 1, castings made by pouring from the top of the conical mold are prone to “internal shrinkage,” which is a pipe-like sink formed in the upper part of the casting; “external shrinkage,” which is a space formed . In Part mode, specify a shrinkage formula: a. It applies to more precise calculations because the actual . Visit this page at the Learning Center to see more about injection mold shrinkage calculation and the mold shrinkage formula.

How to calculate plastic shrinkage?

Shrinkage Rate = 35.

Warpage, or warping, is the distortion induced by the inhomogeneous shrinkage. Plastic Shrinkage Rate Chart Plastic Shrinkage rate is a volume contraction rate of polymers from the melt state and the cooled condition that will determine the .This difference between the thermal expansion of the mold material — typically steel — where the cavity is machined and the rubber compound results in a “shrink rate” calculated as: shrink rate = (cavity dimension – part length) / cavity dimension) [typical units in/in] This shrinkage value is applied to the desired finished part size . This volume contraction of polymers often . Did you find this page helpful? Our goal is to make science relevant and fun for everyone. Published mold shrinkage data, based on simple part geometries and standard molding conditions, is calculated .comASTM D955 Shrinkage From Mold Dimensions – Infinita Labinfinitalab. Shrinkage is based on the compressibility and thermal expansion of the plastics. In mold design, for the sake of simplifying .This Technical Tip briefly explains what mold shrinkage is and why it’s impossible to establish a constant value for PP and PE. Shrinkage starts at the molecular level when plastics melt and cool.In the mold design, in order to simplify the calculation, the following formula is generally used to calculate the mold size.Molding Shrinkage Calculation (s) lc (mm): Mold dimensions. This formula is used to calculate the molding shrinkage from the .

Injection Mold Shrinkage And Tolerance Knowledge

To research on the influence of gates on molding shrinkage rate, the product structure, material, and processing parameter were kept the .Most of the part shrinkage occurs in the mold while cooling, but a small amount of shrinkage occurs after ejection, as the part continues to cool. For example, if shrinkage by dimension has been defined with the initial formula (1 + S), and if you change the formula to 1/(1–S), the model regenerates from the first affected feature, if the shrinkage is applied by dimension, or from the .comEmpfohlen auf der Grundlage der beliebten • Feedback

Shrinkage and Distortion Calculation

Shrinkage Rate will be –.Plastic Shrinkage Rates |Mold shrinkage chart | plastic .α= (L0−L)/L0 . Perform one of these operations: On the Mold tab, click the arrow next to Shrinkage and then click Shrink by dimension or Shrink by scale. Through a simple mold making technique you can shrink a mold by nearly 25 percent without re sculpting a smaller original.D=M/ (1-s) if the mold cavity is calculated with the known plastic part size and material shrinkage.These dimensional changes are referred to as “shrinkage”.Shrinkage ratio (%) Cavity surface temperature (℃) Injection molding pressure (kgf/cm 2) (MPa) Acrylonitrile Butadiene Styrene polymer ABS: 0.

- Mondo Wickrath Speisekarte | Pizzeria Mondo-Wickrath

- Moderne Kunststoffmaterialien – Zahlen und Fakten zu Kunststoff in Deutschland

- Modulhandbuch Uni Freiburg Psychologie

- Moll Mazda Gebrauchtwagen – Mazda Pickup

- Modern Warfare 2 Update Patch – Call of Duty Releases New Update for MW3 and Warzone

- Mondstein Bilder , „Drachenschuppen“ oder „Reifenspuren“

- Monika Heinrich Tierärztin Heltersberg

- Moe Phoenix Mama Baba , Stream Mama / Baba by Moe Phoenix

- Modèle De Cgv Pour Vente , Modèle de CGV gratuit à copier pour votre site

- Momo Bonn Onlineshop , Rezepte

- Mohnkuchen Vom Blech Mit Schmand