Polyurethane Curing Temperature

Di: Luke

Oil-based polyurethane takes around 24 hours to dry between coats and 48-72 hours to fully cure (harden). There follows an isothermal dwell stage accompanied by reaction shrinkage.Recommended annealing time & temperature is 20 hours at 100o C Typical injection molding processing temperatures of TPU materials are as follows: IM Zone 60A to 75A 80A to 90A 95A to 75D Rear 315 – 40 ºF45 -370 75 400 Middle 340 –365 ºF365 90 85 410 Front 360 –85 ºF75 400 395 20 Nozzle 365 -90 ºF80 405 405 430 Miscellaneous Humidity and Temperature: Polyurethane dries faster in lower humidity and higher temperature. 75 – 95°F (25 – 35°C) Polyurethane Resin.An advantage of the dual curing mechanism is that Carbon can offer a wide range of materials such as elastomer-like polyurethanes (e. A temperature of 70F and 50% .

The starting cure temperature for adhesive 3 occurs at .7 ± 0,5%) was used.During this curing process, the temperature is carefully controlled to ensure that the polyurethane achieves the desired level of hardness and durability. Published: 21 November 2020.Curing Two Part Polyurethane Adhesives.Temperature Range – Mearthaneknowledgecenter. Both components were mixed together at room temperature .The TGA results allowed the selection of an appropriate curing temperature, which was successively confirmed by performing the MEK test on the cured coatings. CE 221) and rigid polyurethanes (e. The polymerization test of TDI powder coatings was performed on coatings cured at 140 and 150 °C for 20 min. The coatings cured at 140 °C dissolved after 15 rubs, which is why the curing time was first extended to 40 min. (c) Saturated . As component 2, MDI mixture (% NCO = 19.

Curing at shorter time and higher temperature is proposed, which is 70oC for 2 hours followed by 100oC for 3 hours (Set B).comEmpfohlen auf der Grundlage der beliebten • Feedback The high percentage of absorption peaks at 2260cm-1.The curing kinetics of the adhesive, in controlled temperature and humidity conditions, was evaluated and an elastomeric product was obtained after curing. The temperature of curing agent 1,4 butanediol, ethylene glycol and 1,6 hexanediol was controlled at about 40 °C and set aside.

Properties of Polyurethane Foams

Accordingly, the nominal processing temperature for MCDEA should be from 95–110°C (203–230°F), typically 100°C (212°F).

The chemistry of polyurethanes

The goal of our research has been to realize dual-curing reaction which is accompanied with radical reaction and urethane reaction at low temperature using a metal acetylacetonate (Mt(acac) x) such as Mn(acac) 3, Mn(acac) 2, Co(acac) 3, Co(acac) 2 and Zn(acac) 2. Published: 02 March 2023.

Polyurethane

Finally thermal contraction occurs as the now solid composite is cooled down to room temperature. The temperature of the . At increased temperatures, the polyurethane will dry faster, at lower temperatures it will take longer.high curing temperature will decrease the water absorption property of polyurethane. indicating that there are lots of isocyanate present in polyurethane [1].The best temperature to apply polyurethane can range from 60°F to 85°F, depending on the type of polyurethane being used. EPU 40), epoxies (e.Herein, we systematically investigated the effects of curing conditions, including relative humidities (25, 35, 45, 55, 65, and 75%RH) and curing duration (0, 0. End-of-life upcycling of polyurethanes using a room temperature, mechanism-based degradation.Polyurethane powder coatings with low curing temperature: Research on the effect of chemical structure of crosslinking agent on the properties of coatings. On the other hand, one disadvantage is that the total processing time of these dual .Introduction to Polyurethane Chemistry. Two component polyurethanes (also called 2C PUR) have the advantages of single component polyurethane adhesives but are able to cure more quickly through larger gaps and are not dependent on moisture or heat to cure.To understand radical reaction relationship depending on what kind of metals, . Long coating life compensates for this in most cases, . However, some polyurethane chemistries can . In the case of powder coatings, the glass transition and melting point should be as high as possible, because otherwise when the melting point is close to the ambient temperature, the powder particles may stick .Polyurethane coatings are made in multiple types compatible with various application methods including: solvent-based polyurethane (SBPU), water-based polyurethane . This leads to frozen-in . High-quality polyurethane coatings can be relatively expensive compared with some other types of coatings.5, 1, 2, 3, 4, .

Publish with us Advanced search.To understand the effect of temperature on the mechanical properties of polyurethane foams and to provide a theoretical basis for the application of polyurethane foams in .Since the cure of one-part, moisture-curing polyurethanes is dependent on moisture diffusing through the polymer, .Polyurethane Recycling and Disposal: Methods and .Preparation of branched polyurethane curing agent by condensation polymerization and radical polymerization. This trend can be seen in Fig.

Polyurethane Temperature Range

Polyurethane dries the fastest in moderate humidity temperatures ranging 70°F (21°C) to 77°F (25°C).netEmpfohlen auf der Grundlage der beliebten • Feedback

Polyurethane’s Temperature Range

1 MPa until the bubbles were eliminated.Typical extrusion processing temperatures of TPU’s are as follows: Extruder 60A to 75A 80A to 90A 95A to 75D Rear 315 – 340 ºF 345 – 370 ºF 375 – 400 ºF Middle 340 – 365 ºF .Instead, choose a wood floor species that does not produce chemicals that will inhibit the drying or curing process.Mixing and testing of polyurethane curing system. For both of the used blocking agents, this deblocking process begins at 140 °C. 1Department of Chemistry, Kansas Polymer Research Center, Pitsburg .The optimal combination of process parameters was a curing temperature of 150 °C, a pultrusion speed of 50 cm/min, a holding time of 12 s, and a holding pressure of 0. (a) Storage modulus depending on curing time of adhesive cured at 45%RH and 20 °C, (b) Storage modulus at 30 °C of adhesive cured at different relative humidity and curing time at a constant temperature of 20 °C. The sprayed coatings on steel plates were first placed in an oven at 140 °C for 20 min. Sprenger and co-workers used a room-temperature curing rubber-toughened epoxy adhesive with a T g of 70°C (Sprenger et al.Thus, it is necessary to minimize this drawback and to try to decrease the curing temperature of NIPU adhesives.Fast-curing polyurethanes were obtained by a one-step method from a two-component system in two NCO:OH ratios (1:1 and 1. Even if the manufacturer’s recommended time has passed, if you can still .Temperature Range.Mechanical properties of PU adhesive.Often, a conditioning or heater–chiller unit is added to control material temperature in order to improve mix efficiency, cure rate, and to reduce process variability. Consequently, the pot life of MCDEA/TDI systems is shorter compared to MOCA/TDI systems, and polyurethane melting temperature must be watched carefully. One hour after curing, a test was conducted on the coatings. Most of these materials cannot tolerate long-term elevated temperatures.Polyurethane’s modulus gradually increases as the temperature is reduced below -18°C (0°F), which increases its stiffness and impacts other performance properties.

Introduction to Polyurethane Chemistry

EPX 82), silicones (e. The dashed lines indicate sigmoid fit as a function of curing time. As BK-Rol 1/2-PU films/coatings outperformed RT-Rol 1/2-PU, the overall results confirmed that curing temperature had a remarkable effect on the performance characteristics of coatings/films.The curing temperature of the powder coatings was selected based on previous study. The optimum ratio between the hydroxyl group of liquefied starch and isocyanate group of PM200 was determined to be 1:1.The mirror is first bonded and cured at room temperature for 9 days (216 h), and then experiences a thermal-vacuum process with a temperature of 34 °C for 16 h (including the rising and dropping stages each for 0. Mechanical property and absorption property of .Improvement of these properties may help achieve lower curing temperatures in coating technologies [19]. This only begins to . The quantitative prepolymer was heated to 85–90 °C and degassed under a vacuum −0.Surfaces finished with oil-based polyurethanes can be used after around 4 days, but full cure normally takes 30 days. The addition of only 4 wt% of 20 nm diameter silica nanoparticles .The drying time of polyurethane sealers depends on various factors, such as the type of polyurethane, the thickness of the applied layer, the humidity and the temperature.When storing polyurethane casting resin, care must be taken to avoid large temperature fluctuations. Morado, Mara L. In this article, we’ll take a closer look at the drying and curing . de Souza,1 Pawan K. To read this content please . In the second . Research Article.Polyurethane powder coatings with low curing temperature: Research on the effect of chemical structure of crosslinking agent on the properties of coatings June 2023 DOI: 10. Polyurethane, (especially water-based polyurethanes), cannot dry below freezing. Kahol,2 and Ram K.@article{Luo2024SolventfreePC, title={Solvent-free polyurethane coatings based on an in-situ curing strategy at room temperature with self-cleaning, anti-corrosion and anti-graffiti properties}, author={Haihang Luo and Huan Wei and Heng Li and Aisong Yao and Yi Chen and Jianming Zhao and Haojun Fan}, journal={Progress in Organic .It is recommended to stack the PU mixture for 4 h before compaction and to cure it for 2 days before opening under the conditions of 50% humidity and 15–40 °C surrounding .The curing temperature of powder coatings was selected based on TG analysis.Low temperatures can affect drying and curing, while high temperatures can shorten working times. By introducing glycerol diglycidyl ether (GDE) as a reaction enhancer, the starting cure temperature of the adhesive can be decreased. Component 1 was polyol mixture with a hydroxyl number L OH = 195 ± 5 mgKOH/g. To speed up polyurethane drying time, apply thin coats, use a hairdryer, lower room humidity, or . SIL 30), cyanate esters (e. As reported by Anna Andersson, high curing temperature with short curing time is insufficient for isocyanate to react completely.In this paper, starch was first liquefied using sulfamic acid as catalyst, and then the starch-based polyurethane coating was prepared.14 MPa, which aided in significantly reducing the deformation of the bezel and achieving effective control of curing deformation. Typically, water-based polyurethane has a slightly . Factors that determine the polyurethane dry time include sealer type, environmental conditions, and coat thickness. The surface properties of the cured .Curing polyurethane typically takes between three weeks and a month, after which the surface is ready for use. Formulations can create flexible, tough materials that absorb considerable .As increasing demand for reducing volatile organic compounds (VOCs) and hazardous air pollutants emissions, two-component waterborne polyurethane (2K-WPU) coatings are . 68 – 77°F (20 – 25°C) Resin cure time is the amount of time required for a resin layer or resin mixture to become hard, durable, and achieve optimal mechanical and chemical properties. Other metallic catalysts Other catalysts such as aluminium, titanium and zirconium complexes are being used in some instances though are not widespread as have lower activity and can require much .gov(PDF) End-of-life upcycling of robust polyurethanes using .

How Long Does Polyurethane Take to Dry? Complete Guide

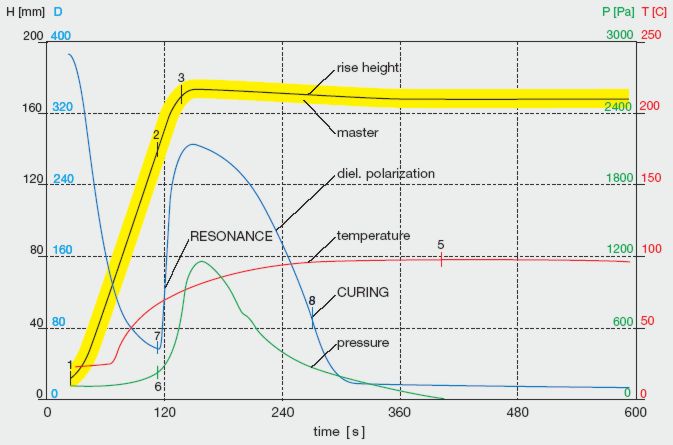

In general, PUR casting resin should be stored at a temperature of 15 to 25 .A typical cure profile involves an initial heating ramp during which the uncured resin is liquid and expands thermally without significant curing.

30 minutes – 2 hours.The results showed that the one‐part ambient temperature curing polyurethane prepared had fast rate of setting and good bonding, meeting the requirements of a typical structural adhesive.1 %, accompanied .Zinc on the other hand results in increased pot life with a good through cure and is especially useful when curing at elevated temperatures (>60 °C)., 2003, 2004; Kinloch et al. At temperatures of around 41°F (5°C), polyurethane can take over three times longer to dry.Applying Polyurethane When It’s Cold – Wood Talk Onlinewoodtalkonline. Differential scanning calorimetry was used to study the curing reaction kinetics of .These polyurethane films/coatings can be used for protective and decorative purposes. Standard thermoset polyurethanes can typically withstand temperatures between -80°F to 200°F. MCDEA exhibits higher reactivity than MOCA. – 80 – 200°F (-62 – 93°C) UV resin. The coatings after this time .5 h), following a post-curing treatment with a temperature of 40 °C for 16 h (including the rising and dropping stages each for . After 30 double rubs using .The research results indicate that when the curing degree increases to 95 %, the overall activation energy of the MDI/1,4-butanediol system decreases by 47. Books and journals Case studies Expert Briefings Open Access.

- Popup Blockieren Firefox – Pop-ups in Chrome blockieren oder zulassen

- Polizeimunition Kosten : Neue Waffen: Bundespolizei rüstet sich für Anti-Terror-Einsätze

- Polizeiinspektion 1 Youtube | Polizeiinspektion 1

- Poptogo Förderung : Über uns

- Polo Neu Ulm Prospekt , POLO Prospekt und Angebote für Neu Ulm

- Polnische Zulassung Erklärung _ Mit dem Fahrzeug nach Polen: Was ist besonders zu beachten?

- ¿Por Qué Es Importante Aprender A Pintar Paredes Correctamente?

- Polo Gti Gebrauchtwagen | Volkswagen Polo Gebrauchtwagen

- Polypenentfernung Abtragung _ Polypenentfernung (Polypektomie)

- Pommes Frites Selbstgemacht Backofen

- ¿Por Qué Digi Mobil Es La Mejor Alternativa?

- ¿Por Qué Debemos Consumir Vitamina E?