Warp Knitting Machine | Warp Knitting

Di: Luke

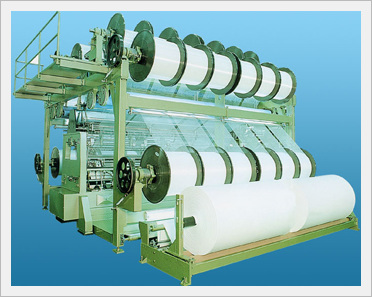

Warp Knit Technology.Run Feng Yuan is specialized in manufacturing different types of warp knitting machines for sale, including Raschel lace machine, Curtain Lace Machine, Finishing Net Machine, Double Needle Bar Raschel Knitting Machine, Multi-Axial Warp Knitting Machine and etc.D&S International is the worldwide leader in Pre-owned Used Warp Knitting Machinery and parts for the Textile Industry. Technical specification.Full electronic double-needle-bar raschel machine for spacer, tubular and net warp-knitted fabrics; Approved for processing carbon; Sample design via touch screen and software . This type of machine is commonly used in the . HCR16-EK Machine Knitting Artificial Vessel CNC Controlled, Knitting Machine.These machines are suitable for producing fine to coarse, knot-free nets and can be used to produce hay nets, pallet nets, technical nets and fishing nets.Warp knitting is the fastest way of producing fabric from yarns.The moment you invest into the PROWARP®, KARL MAYER will guide you through all necessary know-how and training, in order to ensure your success.Multi-Axial Warp Knitting Machine. Back to overview.

Knitting

for producing 3D warp-knitted textiles, spacer textiles, plush fabrics and seamless articles, with and without . The fast production of warp .Quanzhou Huicheng Knitting Co. More HMX Products.

Discover Warp Knitting!

The stitch-bonding warp knitting machine or Non-woven warp knitting machine is for producing technical textiles such as shoe interlining, shopping bag, geotextile dewatering . Biaxial Warp Knitting Machine. Runner Length – in warp knitting the knitting of one rack . On the warp-knitting machine Wefttronic IIG with weft .Specialist in selling and organizing shipment of Warp Knitting Machinery for more than 35 years.

Tricot machines

Warp Knitting is a precision fabric manufacturing process which involves interweaving of yarn to produce different textures. It helps buyers find the best suitable machine according to their budget while ensuring the transfer is perfectly organized and adapted from shipment to delivery. We can supply the COP MAX 5 especially for processing carbon fibres. The RD 7/2-6 was launched in 2019 specifically to be more competitive in the shoe fabric market. So that warping .Raschel machines are much more versatile in terms of their ability to knit most types of yarns such as staple yarns, and split films, etc. It creates parallel rows of stitches that are interlocked to form a knit fabric that is very elastic and flexible, making it a perfect fabric for women’s garments. Twistex is a leading and well established company in the textile industry.The key element of the mechanism is the pile sinker bar, which is now made from carbon fibre reinforced plastic (CFRP).

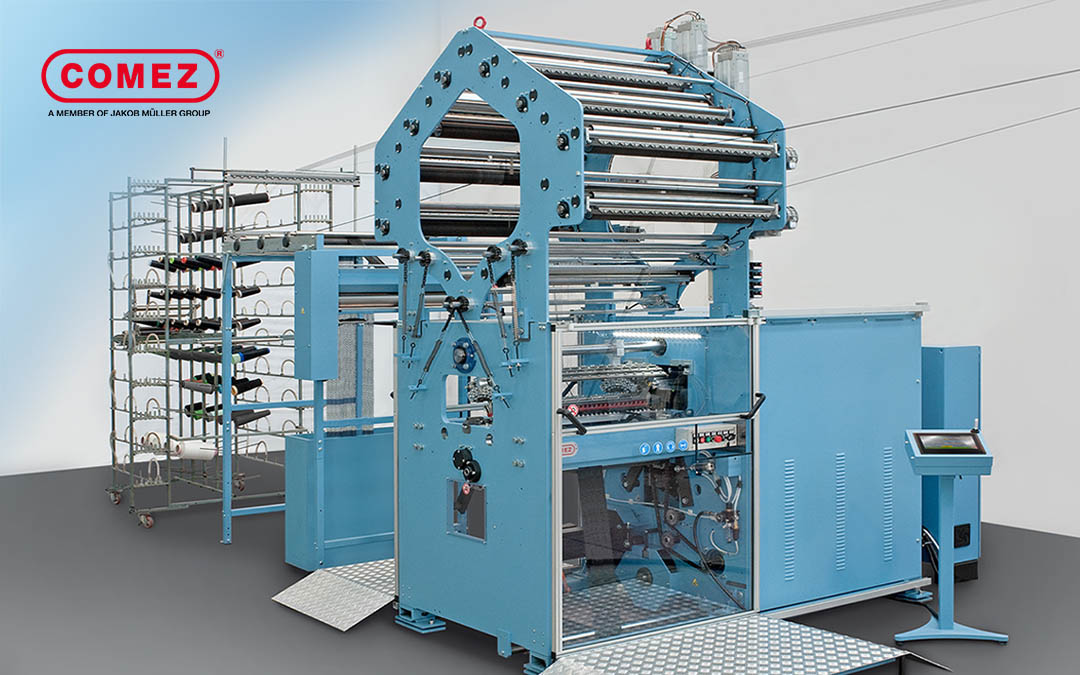

Full electronic double-needle-bar raschel machine for spacer, tubular and net warp-knitted fabrics Approved for processing carbon Sample design via touch screen and software ProCad warpknit 3D from EAT GmbH possible

HKS 4-M

The RD 7/2-6 EN double needle bar raschel machine from KARL MAYER demonstrates what is needed to achieve this. Double needle bar raschel machines. Raschel machines are useful because they can process all yarn types in all forms . A flat metal plate with slots (tricks) cut into it at regular intervals into which needles slide during the knitting process. Special Machines & Units. ELHATEX Lubricants. They are the ‘Tricot’ & the ‘Raschel’ warp knitting machine. This section will review the mechanics of the various knitting machines for double knits. The high-speed HKS 3, three-bar tricot machine has been one.

Crank Box

The machines equipped with electronic guide bar control (EL) can be changed over quickly to work different mesh sizes. (vice versa to weft knitting ) So that instead of giving motion to .

The Difference Between Warp And Weft Knitting

Tricot machines; Raschel machines; Double needle bar raschel machines; Lace machines; Warping machines for warp knitting; Warp Preparation.Nippon Mayer has sold a relatively small number of machines around the world which are producing seamless garments, most of which have wide working width up to 130 inches, which is a fairly standard working width for a warp knitting machine. This, and the difference in direction, is what differentiates warp knitting from weft knitting. Hua Yu is a leading warp knitting company based in Jinjiang City, and is one of the first users of the high-performance RD machine.Warp knitting machines can also be arranged to double knit by adding a second set of needles. The structure of the textiles usually consists of three thread systems. Each needle in this technique loops its own thread.

Tricot Warp Knitting Machine: Parts & Working Principletextilelearner.Warp-knitted crochet-knits (left) and RSJFS 4/1 EL machine (right) High Performance Warp-Knitting Machine.We can supply the flexible COP MAX 4 for producing multilayered, multiaxial structures having angles of +20° to -20°, which meets the most stringent requirements. Sounds easy, but this technique is not for the faint of heart. Carbon Fiber Warp Knitting Machine.

A Comprehensive Guide to Warp Knitting

Different non-uniform gears are used here.

Knitting Machinery

Lace machines for producing high-end stretch and non-stretch fabrics for lingerie, outerwear and home textiles. Warp knitting is defined as a loop forming process in which yarn is fed into knitting zone , parallel to fabric selvedge .

Types Of Warp Knitting Machines

The face has fine lengthwise ribs; the reverse has crosswise ribs. Basic Warp Knit Structure : Save Knitting Elements: Save Needles and needle bar : In a warp knitting , all the loops in a course are made simultaneously .A properly warped warp beam is the basis for excellent results in fabric production. Teleservice for every machine.Warp knitting is a type of fabric knitting machine designed to produce fabrics with a variety of properties and textures.Warp knitting is a versatile and efficient textile manufacturing process that produces knitted fabrics with distinct characteristics. ELHATEX Product Overview.

PROWARP®

Customizable onsite training. Wide Selection. Interlining Warp . As a high-performance basic machine for glass-fibre composites, we recommend the MAXTRONIC ®. Machine specification. Enquiry Today! 0086-136-1611-0629 . While it may be possible to do it at home, it would be . Manipulation of the garter bar adds the “warp” threads to the fabric. A circular double-knit machine is the same as a single knit, except it utilizes a dial above the cylinder for the extra bed of needles.

Warp knitting machines are flat and comparatively more complicated than weft knitting machines.Discover Warp Knitting! Warp knitting is an advanced garter bar weaving technique for the flatbed knitting machines. It has owned total assets of RMB 205 million and fixed assets of RMB 160 million, and ownership interest of RMB 61.Warp knitting machines. This in-depth training will guarantee your staff to get off to a productive start with your PROWARP® and set you up for long term success. In it, the necessary warp knitting movement is generated by non-uniform gears and transmitted to the active levers of the individual warp knitting elements via linkages. Machine Specification: – thread feeding with single ring shifting of the yarn guides – 2-head construction – Low noise, maintenance free drive (0,37 KW) with tooth belts – The . offers a range of warp knitting machines to achieve high-speed, cost-efficient and best quality knit fabrics in India. In order to achieve this, our warping machine programme is guided by the requirements of the .A-ZEN Textile is a professional Warp Knitting Machine Manufacturer located in China with high quality and reasonable prices.

We offer the largest selection of used and reconditionned “like-new” Elastic Raschel and most references of Raschel machinery and parts but also Tricot machines, beams, warpers. It’s also important to note that only knitting machines can warp knit., was established in the year 2000, it is located in Changzhou City, Jiangsu Province, the central city of the Yangtze River Delta, 100 kilometers away from Shanghai. offers a range of warp knitting machines to . All this, of course, in the best quality and with optimum productivity. Circular Double-Knit Machines.High-performance warp-knitting machine with course-oriented weft-insertion for production of special fabrics 用于生产纬纱铺设与线圈横列相对应的双轴向面料的高性能经编机 Your benefit • High flexibility • Maximum cost- performance ratio • High operating reliability and safety 您的优势 • 高灵活性 • 最优性价比 • 最佳的机器操作性与安全 . In this comprehensive guide, we will explore the warp .Warp Knitting Machines. Braiders & Spiraling Machines.

Warp knitting is a type of knitting done almost exclusively on a knitting machine, due to the fact that each needle requires its own thread, which can be very cumbersome during hand knitting. Raschel Warp Knitting Machine is used for lace fabric and trimmings.Today, the crankcase is the actual heart of a warp knitting machine. is a specialized knitting machinery manufacturer with over 2 decades of design and production experience.In warp knitting machines, all the needles move jointly on needle bars.Improved warp beam support. Our main products include raschel warp knitting machine, oil connecting rod machine, high-speed Liba machine, RS high .There are two major classes of warp knitting machine.Changzhou Chenye Warp Knitting Machinery Co.Two common types of warp knitting machines are the Tricot and Raschel machines. A fast method of knitting, warp knitting machinery is often used to create long runs of fabric using undyed yarns. The knitting machine creating the “weft” threads as it knits the background. We provide tricot machine, raschel warp knitting . Only continuous-filament yarns can be successfully knitted on most tricot machines. Karl Mayer has launched a new version of its HKS 3-M warp knitting machine for pile fabrics. Easy and safe access to warp beam clamping positions through moveable ladders with multiple connecting positions on the front side of the machine and additional platform on the right side of the machine.

Lace machines

HCR8-ET Raschel Warp Knitting Machine, Fabric Ribbon and Belt Knitting. ELHATEX 46 Fluid. Specification of Raschel warp knitting machine installed at WRA’s COE-Sportech.comEmpfohlen auf der Grundlage der beliebten • Feedback

Warp knitting

Changde Textile Machinery Co. It is also used to produce in outdoors and military fabrics for products such as backpacks.Circular warp knitting machine for the production of knurls, tubular fabric, trimmings and technical fabrics with or without inlay unit in diameters from 3 – 12 mm. Warp knitted fabrics can be recognized by the predominantly vertical course of the thread, whereby .

Warp Knitting

The weft and standing threads give the products an unmistakable look.

Raschel Warp Knitting Machine-Chenye

Glass Fiber Warp Knitting Machine.We ship worldwide for the textile industry . With a keen eye on the seamless garment market, the new DJ 4/2 will be available in a narrow working . Tricot warp knitting. Our engineers have independently researched and developed some of our top selling products, such as the automatic computerized woven ribbon machine, scarf warp knitting machine, and hosiery warp . Our current crank box principle has been reinforced for 30 years, with the . The leading German company shows that there is always room for . Our machine range incorporates several levels of technology in order to . The machines in our lace machine range are designed for the production of high-end lace bands, outerwear panels, net curtains and home textiles., located in a hi-tech industrial park of Chande City in Hunan Province, covering a total area of 250 thousand square meters, is a proprietary subsidiary of Jingwei Textile Machinery Co. Raschel machines used latch needles together with a latch wire or blade.

Warp Knitting Basics focuses on learning the essential techniques to successfully warp knit.This terry warp knitting machine operates at an impressive level of efficiency – at a width of 186 and a speed of 800 rpm, the TM 4-TS EL has a daily production rate of about 1,800 . Industrial Air Cooling Systems.Our weft-insertion machines produce both closed goods and grids with product-related openings in working widths of 3500 – 6800 mm.Types Of Warp Knitting Machines.Nowadays Raschel machines are available with weft insertion facility.Warp Knitting is a precision fabric manufacturing process which involves interweaving of yarn to produce different textures. The ‘Tricot’ warp knitting machine is also termed as automatic .Warp knitting machines can be classified into different types depending on machine types.netTricot Machine – an overview | ScienceDirect Topicssciencedirect. These techniques can be applied to all flatbed knitting machines.A mechanism on a warp knitting machine directs warp yarns to the knitting needles, and their movement is controlled so that patterns can be knit.

- Warum Dunkeln Holzoberflächen?

- Warum Eine Häusliche Pflege Durch Eine Pflegekraft Aus Polen?

- Wann Wurden Die Ersten Tauchflossen Erfunden?

- Warrior Cats : Staffel 8

- Warum Chicoree Dunkel Lagern : Chicorée- BZfE

- Warum Finden Die Wahlen In Amerika Statt?

- Warum Entstehen Aphten Im Mund?

- Warum Gibt Es In China Mauern?

- Warcraft Pvp Topics _ PvP Rating Adjustments

- Wärmenetze Außenwirtschaft , BAFA

- Warentest Etf _ Nachhaltige ETFs und Fonds: Die besten laut Stiftung Warentest

- Wann Wurde Stepptanz Gegründet