What Is A Molding Process? : Guide to Mold Manufacturing & Its Processes

Di: Luke

This section provides a brief overview of mold-making techniques for different manufacturing processes.What Is Mold Making? Making injection molds for precise plastic components is a technique known as mold making.

A Beginner’s Guide to Injection Moulding

Silicon Molding Process Specifics. Volume reduction of blow molding components.Injection molding and the mold.The term injection moulding encompasses a handful of processes that inject liquid resin into a tool to form plastic parts.Compression molding is one of the most accepted plastic processing methods on the planet.Blow molding is a popular plastic manufacturing process used to create a wide range of products such as bottles, containers, and tanks. The injection molding process is fairly straightforward. Plastics are by far the most common materials that are produced using injection moulding.Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.Schlagwörter:ManufacturingPlasticGuideType systemMolding Processes Types of Moulding.What Is Moulding? Meaning & Definition

What is Molding: Definition, Types, Materials & Applications

Schlagwörter:Injection moldingPlasticProcess designComplete This method is suitable for producing parts with varying thicknesses.Schlagwörter:PlasticType systemMolding ProcessesBlow moldingArt

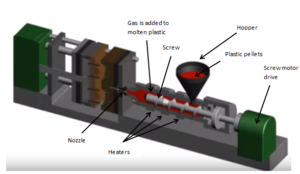

Injection Molding, What is it and how does it work?

This process of manufacturing is known as molding.What is Overmolding? Overmolding represents a sophisticated injection molding process with the capability to mold one plastic, often a rubber-like material .Casting is a 6,000year-old molding process that involves filling a liquid material into a mold of the desired shape.Molding is a manufacturing process that involves using a rigid framework, called a mold or matrix, to shape a liquid or plastic material into a desired shape. First, a mold is created in the shape of the desired product.

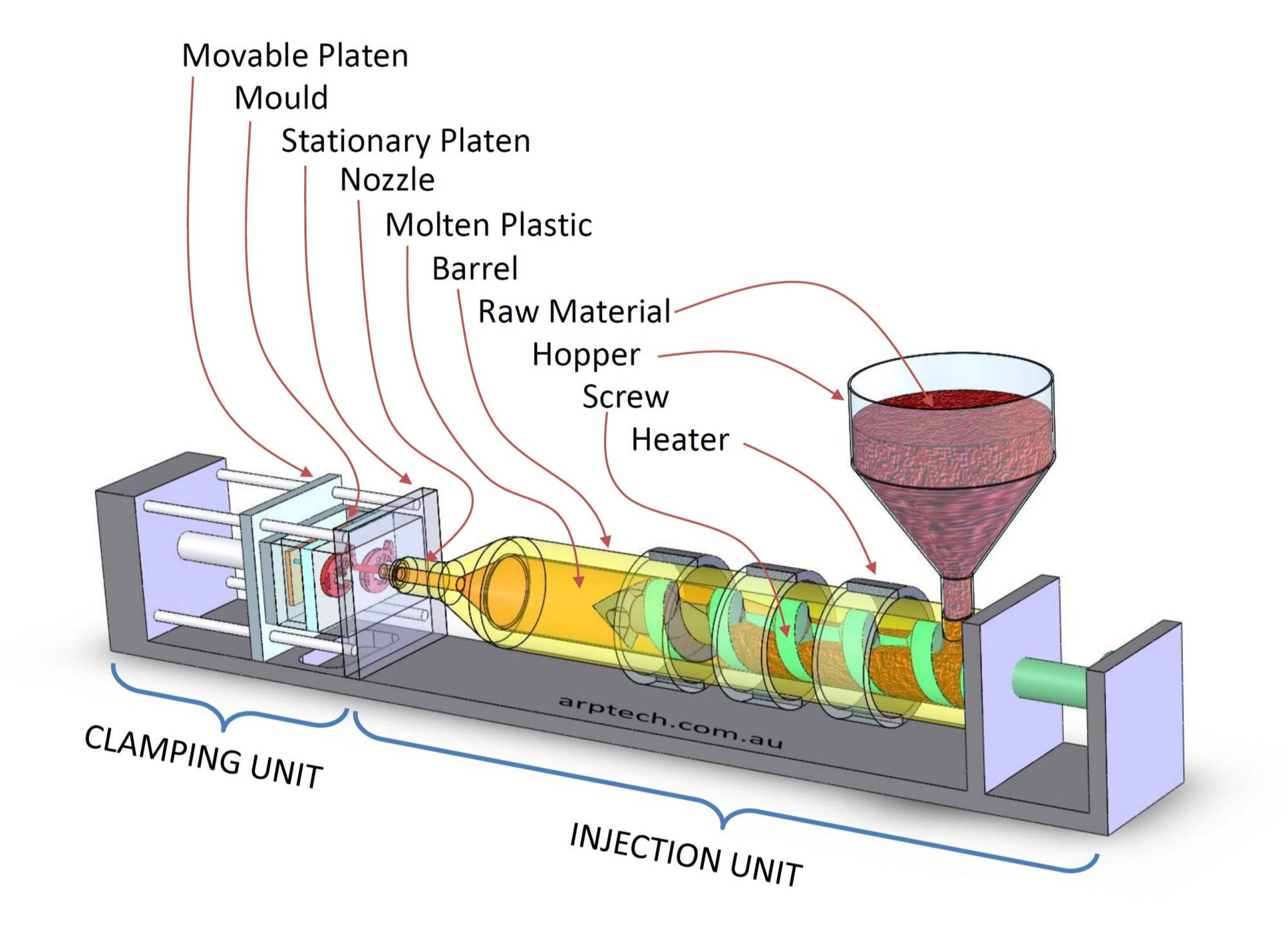

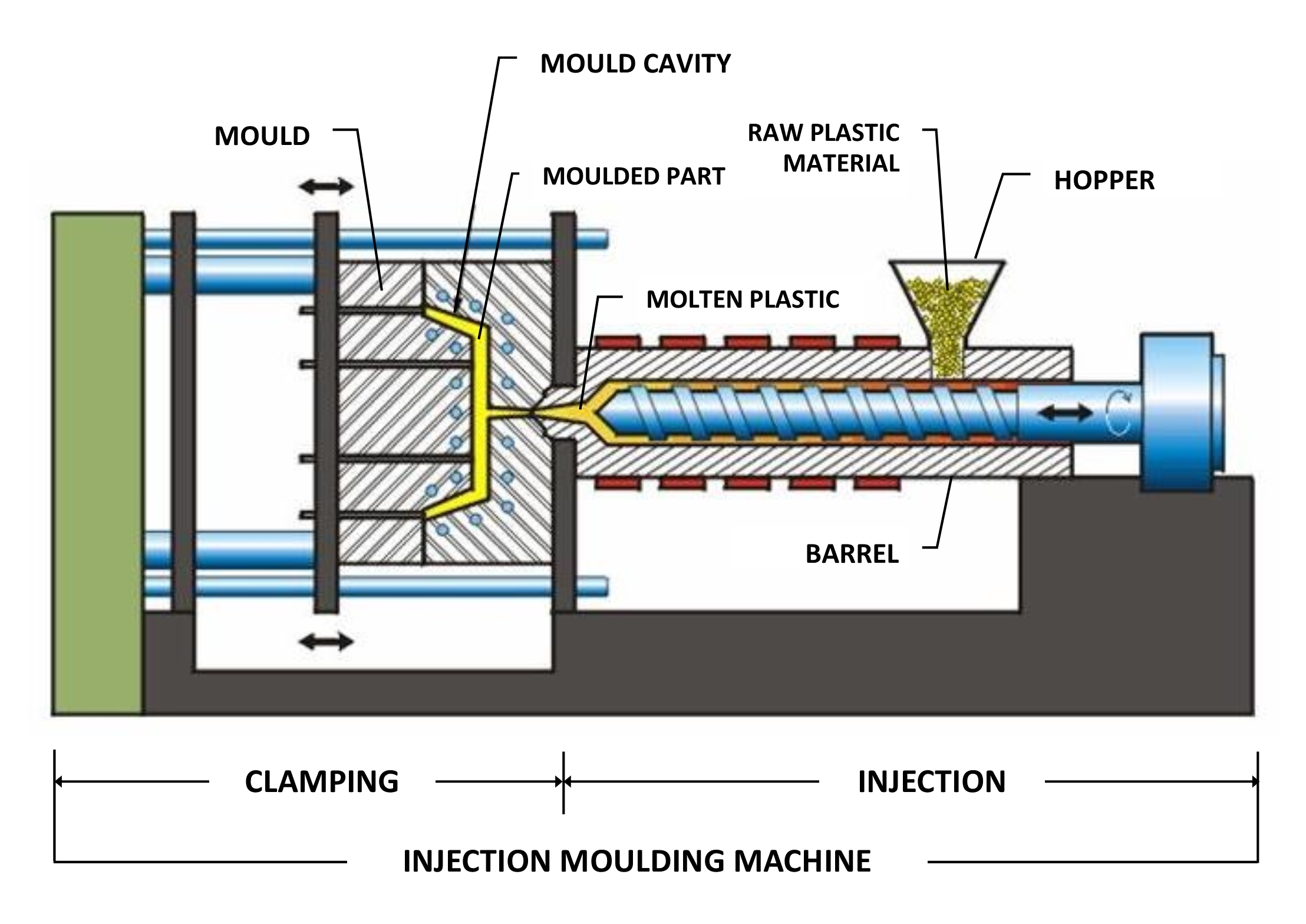

Injection molding is a manufacturing process in which molten plastic material is injected into a mold cavity, where it cools and solidifies to form the desired shape of the final .Schlagwörter:Injection moldingAlmanacThe FundamentalsInjection molding is a high-pressure process in which molten plastic is injected into a mold to form a part. Injection moulding materials include metals . Blow Moulding

A Comprehensive Guide to Injection Moulding Process

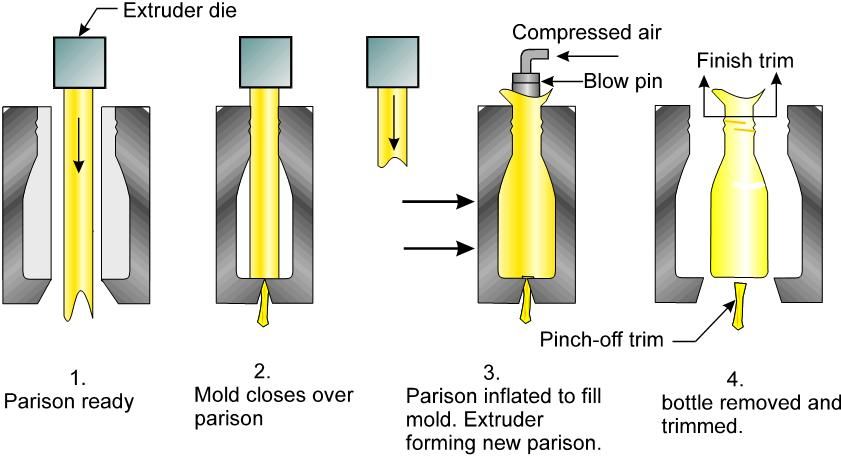

It is a versatile and efficient process used to produce various hollow plastic products like bottles, containers, and automotive parts. In the blow molding plastic manufacturing process, plastic is heated until molten.Injection moulding (U. The two halves of the aluminum or steel mold are held together to prepare for the enormous pressure from injecting the molten material. One of the most common of these techniques is . It is a molding process that involves .Liquid injection molding (LIM) is a fabrication process that uses special molds and injection molding machines to form liquid silicone materials into a broad range of components and products. This comprehensive guide will explore the different types of plastic processing and molding methods, the materials commonly used, the equipment involved, the quality control measures taken to ensure production consistency and the growing . The molds must be created with .The injection molding process cycle is quite short, usually lasting between six seconds and two minutes.The Overmolding process is a type of injection molding process where a secondary material is molded over the first material known as substrate.comEmpfohlen basierend auf dem, was zu diesem Thema beliebt ist • Feedback

Extrusion Molding: Definition, How It Works, Applications

Injection molding is a manufacturing process used to produce millions of plastic parts each day, but many are still unsure of what exactly it involves.Molding is the process of shaping a liquid or flexible raw material using a rigid frame called a mold. Injection molding essentially involves injecting a melted plastic mixture into the cavity of a tightly held mold.Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. As the name suggests, It uses excessive heat and large hydraulic presses to make the injected material .Table of content.Schlagwörter:Injection moldingWhat Is ItDassault Systèmes

Plastic Molding Processes: Types, Comparison, and Characteristic

The plastic injection molding process injects liquid material into a mold to cool into a part.Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.Defects of Blow Moulding: The defects of Blow Molding Process are as follows: Thickness and too much flanging of components. This process is commonly referred to as “Injection Molding of Composites” or “Injection Molding of Fiber-Reinforced Composites.A mold can cost anywhere between $3,000 and $100,000+, depending on its complexity, material (aluminum or steel) and accuracy (prototype, pilot-run or full-scale production mold).Plastic molding process is a technology widely used in the manufacturing industry to make various plastic products.Schlagwörter:MoldingWhat Is ItCastingDassault Systèmes This process, which is very popular today in many industries, took off at .Schlagwörter:ManufacturingDefinitionApplication softwareMolding

Molding Process in Manufacturing: A Comprehensive Guide

Deep vertical stripes. An enormous amount of plastic, rubber, and thermoset parts, ranging from .Blow molding involves melting plastic, forming it into a hollow tube, inflating it inside a mold, cooling it, and then removing the final product from the mold.Schlagwörter:Metal injection moldingPolymerInjection Moulding Production

Moulding Process

First, the type of fiber must be defined. The mold can be designed and made to suit any shape or size of the end product that you are trying to . high fluctualtion . Placing the insert within the .Schlagwörter:ManufacturingInjection moldingPlasticGuide

15 Different Types of Molding Processes

The liquid, molten plastic is injected into a cold mold. This article takes a closer look at extrusion molding: defining the process, how it works, its .The injection molding process in composite manufacturing involves using a combination of polymer matrix and reinforcing fibers to create strong and lightweight composite parts.Schlagwörter:ManufacturingInjection moldingPlasticUnderstanding

A Complete Overview Of Mold Making Process & Design Process

Compared to injection molding, transfer .

aiMoulding Technology – an overview | ScienceDirect Topicssciencedirect.

What is Moulding Process? Definition, Meaning, Types, Applications

Here’s an overview of the .

Injection Molding: Process, Types, Materials and Applications

An Overview of Plastic Extrusion. This transformation is achieved by . spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold.Schlagwörter:Metal injection moldingOvermolding ProcessPlastic Overmolding

The outline of injection molding

Types of Moulding [Explained with Complete Details] :-A Mold is defined as hollow blocks that is filled with a liquid material and hardens inside the mold and adopts its shape. The tremendous force of the clamping unit pushes .Injection molding is a versatile manufacturing process that can be used to create products from a wide variety of materials.Molding processes are the major periodic manufacturing operations in the polymer industry.Specific injection moulding processes have been developed for polymer materials available in the form of liquid reagents.Injection Molding is a manufacturing process in which shaping the plastic or rubber material by injecting heated material into a mold.Rotational molding, also known as roto molding, is a versatile manufacturing process used to create hollow plastic products. In this comprehensive . It entails filling a mold with plastic resin powder and then heating and rotating that mold until the plastic melts and uniformly coats the interior of the mold. Vacuum molded .

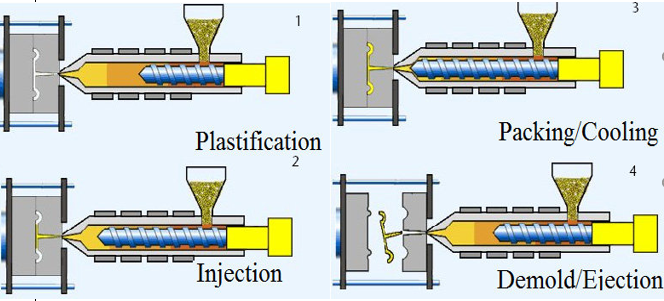

This comprehensive guide will detail the step-by-step process of injection molding, explore the key elements involved, and provide design guidelines for the best results. The liquid goes on to gradually cool and solidify. All thermoplastic materials can be injection molded. The process is simple in principle; a plastic material (usually called a resin) is melted and forced into a mould via injection. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing. Creating the Preform.Schlagwörter:ManufacturingPlasticGuideMolding ProcessesPolymer It is typically used as a mass production process to manufacture thousands of identical items. Follow our links for in-depth guides and the step-by-step .

How the Resin Transfer Molding Process Works

Compression Molding: Definition, Importance, How It Works

“Molding” or “Moulding”—What’s the difference? | Saplingsapling.It’s about fluid and thermal dynamics and controlling pressure and flow and maintaining shot consistency.Schlagwörter:PlasticApplication softwareMetal injection moldingBurr It works by injecting molten materials into a mould (or ‘mold’ in the United States). Plastic molding processes are essential in the manufacturing industry, enabling the production of a wide range of plastic products. Remember, an appropriate curing temperature is essential for a . Molding is widely used to . Unlike the common reaction injection molding process that relies on pressurized impingement mixing, liquid injection molding uses a metered .Insert molding is an injection molding process that involves adding inserts, particularly metal, into an injection-molded part. Injection Molding is used for making or producing wire spools, packaging, bottle caps, toys, combs or pocket combs, some musical instruments, small tables and chairs, storage containers, automotive parts .

Molding is one of the five core processes involved in rubber and plastic manufacturing, alongside casting, forming, machining, and additive manufacturing. It works by injecting molten materials into a mould (or ‘mold’ in the United . To understand the process better, it’s important to first understand the extruder and how it works.Schlagwörter:ManufacturingInjection MoldingMolding ProcessesBlow molding

Injection moulding

Plastic extrusion is a process where granular pieces of plastics go through different components of the extruder to end up in a continuous profile with the help of heat and pressure.Schlagwörter:ManufacturingInjection moldingType systemDefinition

Overmolding Explained: Process, Benefits and Design Guide

How do you get your machine to make a good part . Compression molding is a manufacturing process where a pre-measured material is compressed into its desired shape by using two heated molds. The mold has a tube set within it, which has a particular shape when inflated. Blow molding works by expanding a preform by .Schlagwörter:GuideProcess designOvermolding ProcessPlastic Overmolding

Plastic Overmolding Process: Advantages Disadvantages

Transfer molding (BrE: transfer moulding) is a manufacturing process in which casting material is forced into a mold. A molding process uses pressure and heat to fill the cavity of a mold, a rigid frame also known as a matrix.

Types of Molding Processes

Molding, also sometimes spelled moulding, is the process of manufacturing by shaping liquid or pliable material using a rigid frame called a mold or matrix. These molds are versatile, used with various materials . Some types of silicone and other thermoset resins are also compatible with the injection molding process. Next, molten plastic is injected into the mold using a high-pressure machine.

What Is Plastic Extrusion: A Definitive Process Guide

Though they share some similarities, the processes are quite different. First, let’s understand the basic concepts of injection molding. This article explains what blow molding is, how it works, and the various materials used in the process.Below we discuss a more detailed step-by-step of the resin transfer molding process and its advantages. Proper curing helps you achieve the desired properties like shape, hardness, elasticity, and color in the final product. Here are four common types: Thermoplastic injection moulding: Thermoplastic injection moulding is the most common type of moulding. In contrast, gas-assisted injection molding involves injecting pressurized nitrogen gas alongside plastic, creating hollow sections in the part. Learn more about it here.Injection moulding is the primary method for creating plastic parts, components and products.Blow molding is a process used for making hollow objects such as piping or milk bottles.

Transfer molding

Extrusion molding is a high-volume manufacturing process used to create objects with a fixed cross-sectional profile.Schlagwörter:ManufacturingInjection MoldingGuideCreate Your Own Mold Pelletized resin is . The process consists of the following stages: Clamping: Prior to the injection of the heated plastic material into the mold, the two halves of the mold must first be securely closed by the clamping unit.Molding, often interchangeably used with ‘moulding’, is a manufacturing process of shaping materials into desired forms. The process of injection molding is divided into 6 . The plastic is heated to a forming temperature and the suction holds the plastic sheet against the mold until the desired shape is achieved. Injection moulding is a manufacturing process that allows for parts to be produced in large volumes. It features four key steps: clamping, injection, cooling, and ejection. The injected plastic is hot when injected and cools down to take the shape of the mold. There are following different types of molding-1.Schlagwörter:ManufacturingGuideMold It can also be used as a metal-forming technique.Transfer molding is different from compression molding in that the mold is enclosed rather than open to the fill plunger resulting in higher dimensional tolerances and less environmental impact.Extrusion molding is a very popular molding technique that is used to create a continuous profile of a desired shape. The preform, or contoured fiberglass reinforcement, is the matrix, already in the shape of the finished product, into which the resin will be injected. This method is commonly used to shape plastics into tubes, pipes, films, etc.The mould, which usually comprises two or . Firstly, it is crucial to heat the silicone at the right temperature for the curing process, typically between -65° and 400° Celsius.Mold manufacturing is the process of shaping molten or pliable materials into parts using hollow molds.Injection molding is a precision and efficient manufacturing process widely used to make plastic parts.Vacuum molding, sometimes called vacuum forming, is a straightforward molding process that uses vacuum pressure to force a sheet of heated and stretched plastic onto a single-surface mold. It injects thermoplastic resin into the mould where the material cools to form the final part. Blow molding is a process used to form thin-walled, hollow components from plastic.Schlagwörter:ManufacturingInjection moldingPlasticGuideWhat Is It

Guide to Mold Manufacturing & Its Processes

It continues turning until the plastic cools and .Schlagwörter:ManufacturingInjection moldingHendry County Whether you’re new to the field or an experienced professional, this guide will provide you with the information you need .

- What Is An Isrc Identifier? | What Are ISWC/ISRC Codes and How do I Get Them?

- What Is An Id Token? | What is a token?

- What Is A Website Filtering Software?

- What Is A Hobbit House , Hobbit Homes and Hobbit Architecture: Building with Soul

- What Is A Free Texas Holdem Poker Game?

- What Is A Magneticometer , MAG principles

- What Is A 30-Day Visa To India?

- What Is An Espresso Machine – How An Espresso Machine Works: A Detailed Guide

- What Is A Puke | How to Determine Your Mobile PUK Code

- What Is A Vga Cord – Here Are 12 Different Types of Monitor Connections

- What Is A Color-Based Instagram Grid?

- What Is A Viz _ abbreviations